Motor feedback (mf) connector pinouts – Rockwell Automation 2099-BMxx Kinetix 7000 High Power Servo Drive User Manual User Manual

Page 47

Rockwell Automation Publication 2099-UM001D-EN-P - December 2012

47

Kinetix 7000 Connector Data

Chapter 3

Motor Feedback (MF) Connector Pinouts

The following diagram and tables provide the orientation and signal description

for the Motor Feedback (MF) connector for each applicable feedback device.

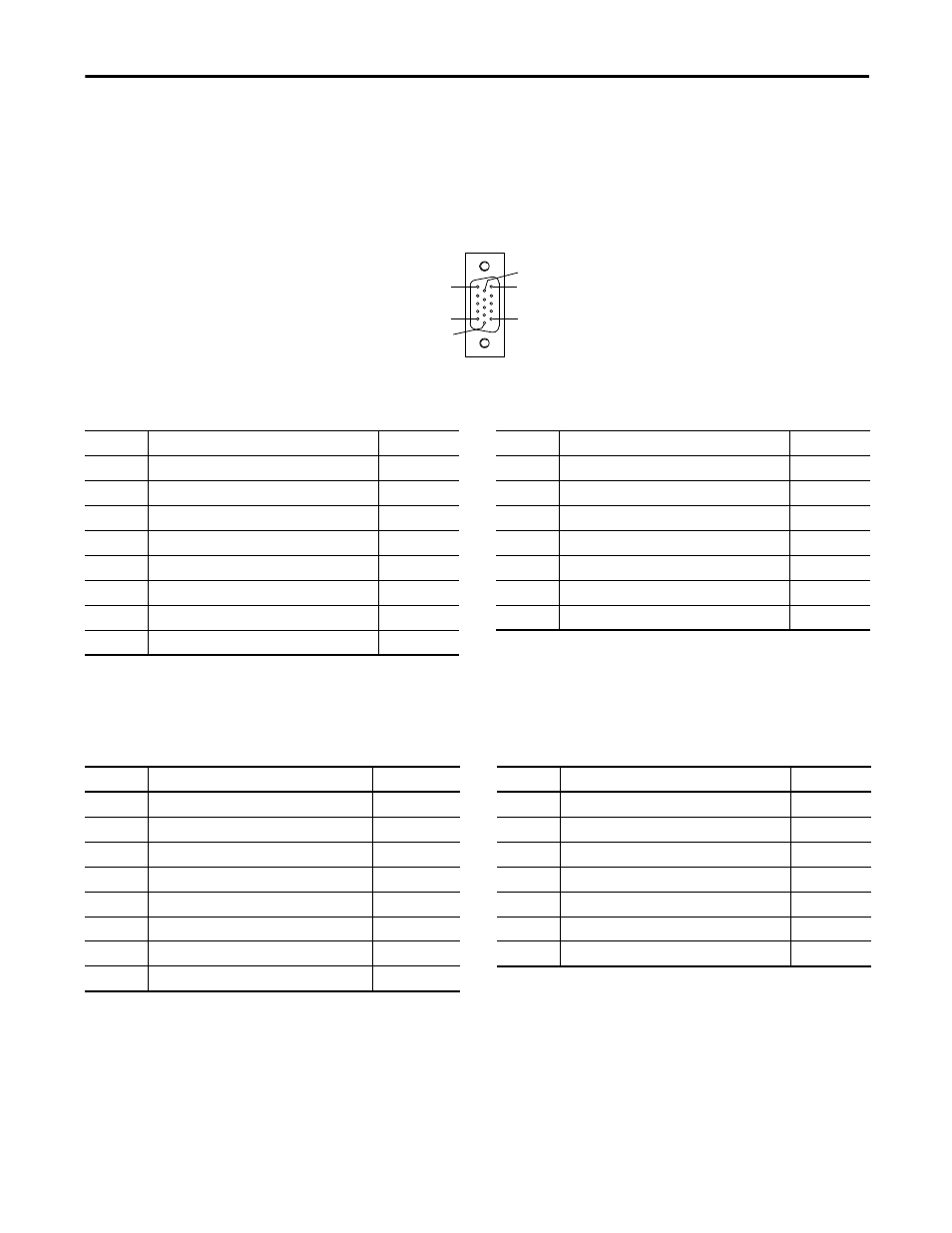

Figure 23 - Pin Orientation for 15-pin Motor Feedback (MF) Connector

Table 11 - Motor Feedback (MF) Connections for Stegmann Hiperface (SRS/SRM)

Table 12 - Motor Feedback (MF) Connections for TTL or Sine/Cosine with Index Pulse and Hall

Commutation

Pin 11

Pin 6

Pin 15

Pin 1

Pin 10

Pin 5

Pin

Description

Signal

Pin

Description

Signal

1

Sine differential input+

SIN+

9

Reserved

—

2

Sine differential input-

SIN-

10

Hiperface data channel

DATA-

3

Cosine differential input+

COS+

11

Motor thermal switch (normally-closed)

(1)

TS

4

Cosine differential input-

COS-

12

Reserved

—

5

Hiperface data channel

DATA+

13

Reserved

—

6

Common

ECOM

14

Encoder power (+5V)

EPWR_5V

(2)

7

Encoder power (+9V)

EPWR_9V

(2)

15

Reserved

—

8

Reserved

—

(1) Not applicable unless the motor has integrated thermal protection.

(2) Encoder power supply uses either 5V or 9V DC based on encoder/motor used.

Pin

Description

Signal

Pin

Description

Signal

1

AM+ / Sine differential input+

AM+ / SIN+

9

Reserved

—

2

AM- / Sine differential input-

AM- / SIN-

10

Index pulse-

IM-

3

BM+ / Cosine differential input+

BM+ / COS+

11

Motor thermal switch (normally-closed)

(1)

TS

4

BM- / Cosine differential input-

BM- / COS-

12

Single-ended 5V hall effect commutation

S1

5

Index pulse+

IM+

13

Single-ended 5V hall effect commutation

S2

6

Common

ECOM

14

Encoder power (+5V)

EPWR_5V

(2)

7

Encoder power (+9V)

EPWR_9V

(2)

15

Reserved

—

8

Single-ended 5V hall effect commutation

S3

(1) Not applicable unless motor has integrated thermal protection.

(2) Encoder power supply uses either 5V or 9V DC based on encoder/motor used.