Rockwell Automation 2099-BMxx Kinetix 7000 High Power Servo Drive User Manual User Manual

Page 141

Rockwell Automation Publication 2099-UM001D-EN-P - December 2012

141

Troubleshoot the Kinetix 7000 Drive System

Chapter 6

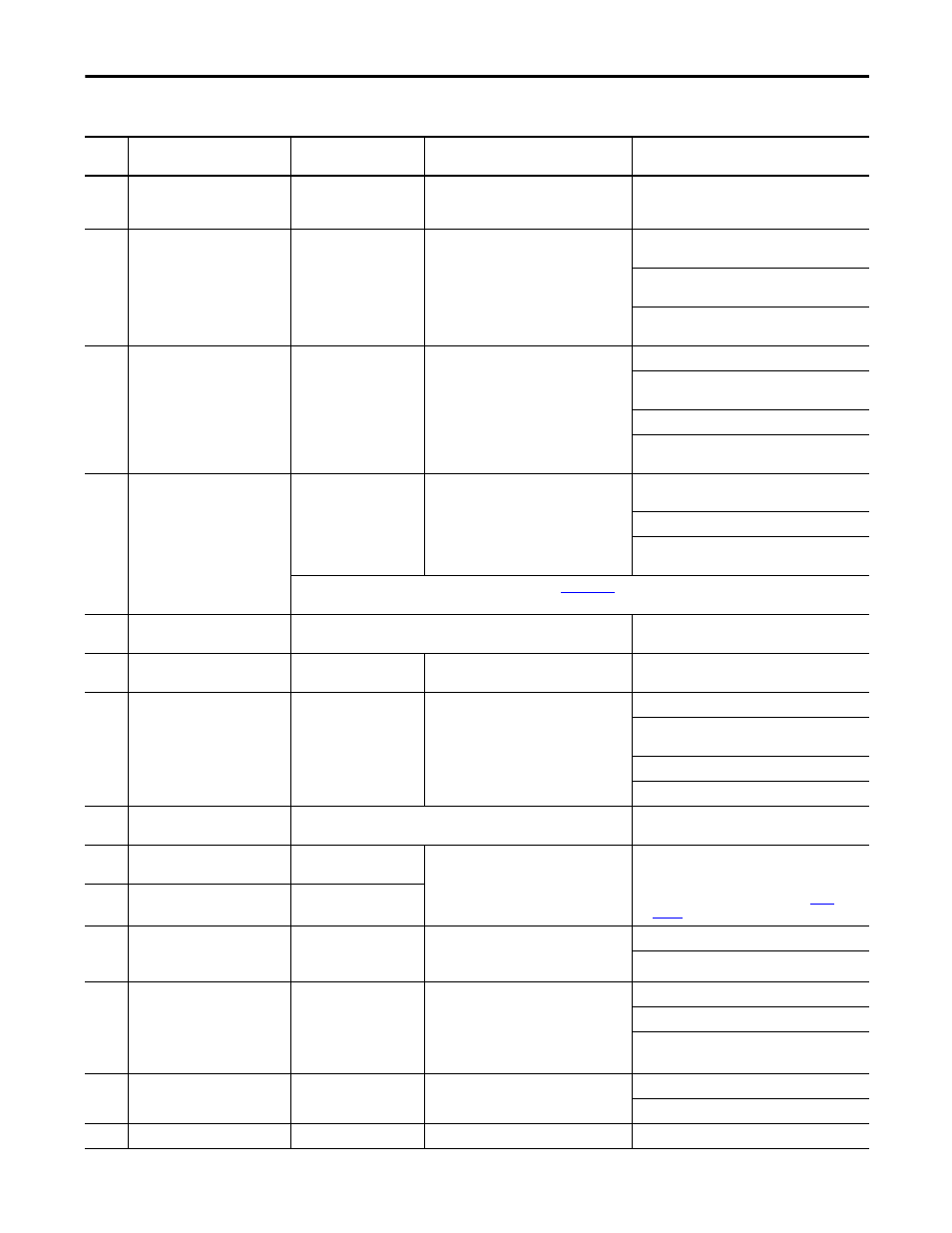

E38

SERCOSFault

The SERCOS ring is not active

after being active and

operational.

Cable disconnected.

Check that fiber-optic cable is present and properly

connected.

E39

DriveHardFault

Self-sensing Commutation

Startup Error.

Obstruction prevents motion required for self-

sensing startup commutation.

Verify that there are no impediments to motion at

startup, such as hard limits.

Increase self-sensing current if high friction or load

conditions exist.

Check motor or encoder wiring using wiring

diagnostics.

E43

DriveEnableInputFault

Missing Drive Enable input

signal.

Attempted to enable the axis through

software while the Drive Enable hardware

input was inactive.

The Drive Enable input transition from active

to inactive occurred while the axis was

enabled.

Disable the Drive Enable Input fault.

Verify that Drive Enable hardware input is active

whenever the drive is enabled through software.

Verify wiring and shielding.

If error persists, return the drive to Rockwell

Automation.

E49

DriveHardFault

Safe-off function mismatch.

Drive will not permit

motion.

Loose wiring at SO connector.

Cable/header not seated properly in SO

connector.

Safe-off circuit missing +24V DC.

Verify wire terminations, cable/header connections,

and +24V DC.

Reset error and run proof test.

If error persists, return the drive to Rockwell

Automation.

Refer to the Kinetix Safe-off Feature Safety Reference Manual

r additional troubleshooting information and proof test

procedures.

E50

SERCOSFault

Duplicate node address detected on SERCOS ring.

Verify that each SERCOS drive is assigned a unique

node address.

E54

DriveHardFault

Excessive Current Feedback

Offset.

Defective current feedback sensing.

If error persists, return the drive to Rockwell

Automation.

E61

AuxFeedbackFault

Auxiliary Encoder State

Error.

The auxiliary encoder encountered an illegal

transition.

Use shielded cables with twisted pair wires.

Route the feedback away from potential noise

sources.

Check the system grounds.

Replace the motor/encoder.

E62

AuxFeedbackFault

The feedback wiring is open, shorted, or missing.

Check the motor feedback cable connectors/wiring

to the drive and motor.

E63

AuxFeedbackNoise

Noise on auxiliary feedback

cable.

Recommended grounding, per installation

instructions, has not been followed.

• Verify grounding.

• Route feedback cable away from noise sources.

• Refer to System Design for Control of Electrical

Noise Reference Manual, publicatio

.

E64

MotorFeedbackNoise

Noise on motor feedback

cable.

E65

No Fault Message

(condition indicated by on-screen

message)

Hookup procedure failed.

Motor or feedback device malfunction.

Check motor power/feedback wiring.

Refer to displayed message for resolution.

E66

No Fault Message

(condition indicated by on-screen

message)

Autotune procedure failed.

Motor or feedback device malfunction.

Check motor power/feedback wiring.

Refer to displayed message for resolution.

Perform Hookup in RSLogix 5000 software.

Consult RSLogix 5000 help message.

E67

DriveHardFault

Operating system failed.

Software initialization fault detected due to

hardware failure.

Cycle power.

If fault persists, replace module.

E68

DriveHardFault

DPI communication failed.

The DPI device or cable is faulty.

Check DPI connections.

Table 50 - Seven-segment Status Indicator Error Codes (Continued)

Error

Code

Fault Message RSLogix

Anomaly or Symptom

Potential Cause

Possible Resolution