Rockwell Automation 1203-CN1 ControlNet Communications Module 1203-CN1 User Manual

Page 66

Publication 1203-5.13 – February, 2002

5-6

PLC Ladder Logic Programming

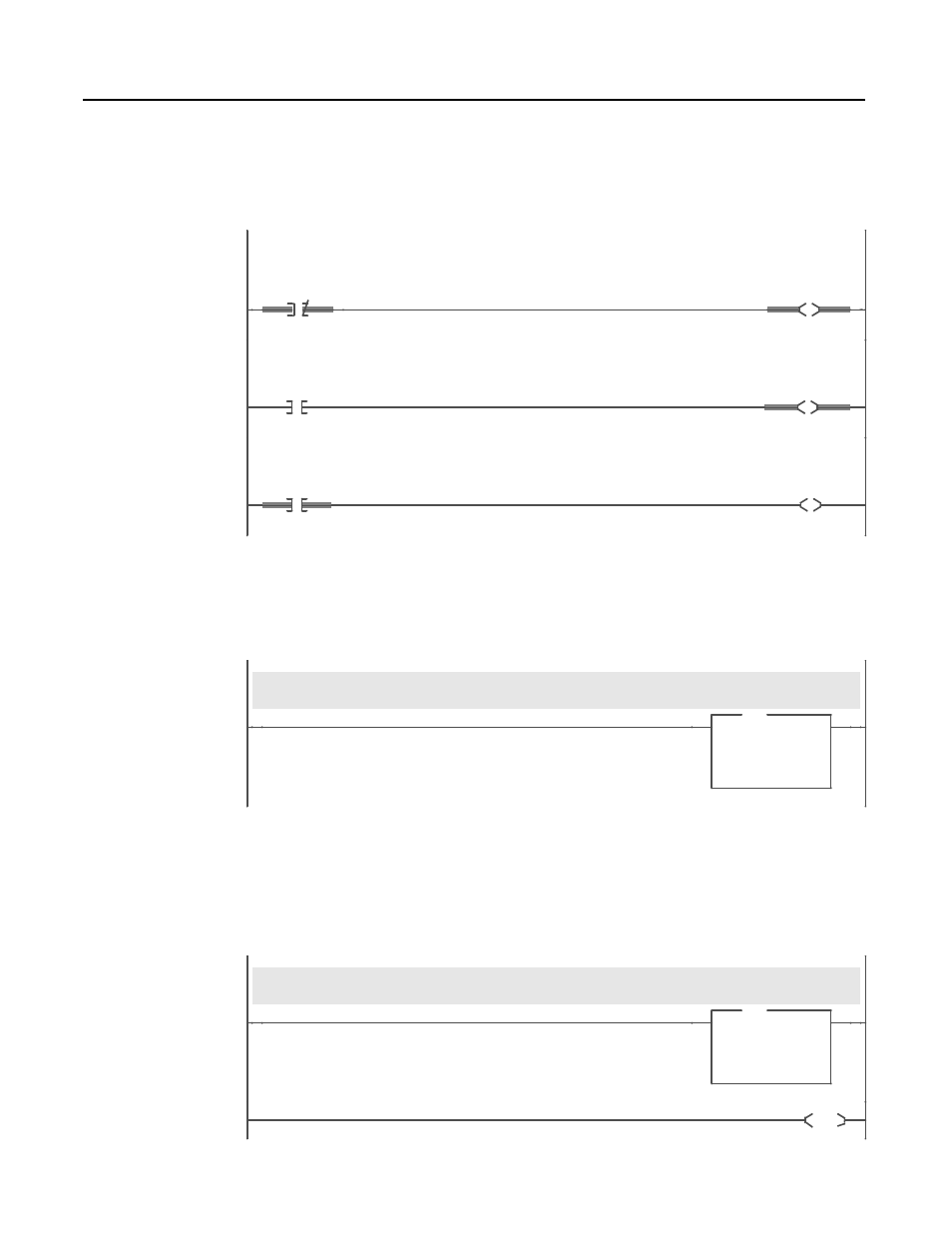

The portion of the program shown in Figure 5.4 displays the status of

the drive by reading the status information in the drive’s logic status

word and displaying it at the operator’s station.

Figure 5.4

Drive Status Display logic

The portion of the program shown in Figure 5.5 moves a Frequency

Reference to the drive. The word is scaled 0 to 32767 equals 0 to

maximum frequency. Scaling may differ for other products.

Figure 5.5

Drive Frequency Reference

The portion of the program shown in Figure 5.6 moves the drive’s

Frequency Feedback from the drive’s feedback word to the PLC. The

word is scaled 0 to 32767 equals 0 to maximum frequency. This

scaling may differ on other SCANport products.

Figure 5.6

Drive Frequency Feedback Display

Status Display Logic

0003

N12:0

0

Drive

ENABLED

Status

Bit

O:000

0

Operator

Drive Enabled

Status

Display

0004

N12:0

1

Drive

RUNNING

Status

Bit

O:000

1

Operator

Drive Running

Status

Display

0005

N12:0

7

Drive

FAULTED

Status

Bit

O:000

2

Operator

Drive Faulted

Status

Display

Frequency Reference

This rung moves a frequency reference from N7:0 to the drive's FREQUENCY REFERENCE input word at N13:1.

Frequency scaling on the 1305 AC Drive is such that 0 - 32767 = zero - max frequency.

0006

MOV

Move

Source

N7:0

16383<

Dest

N13:1

16383<

MOV

Frequency Feedback

This rung moves the drive's FREQUENCY FEEDBACK from the drive's feedback word at N12:1 to N7:1.

Frequency feedback scaling on the 1305 AC drive is such that 0 - 32767 = zero to max frequency.

0007

MOV

Move

Source

N12:1

0<

Dest

N7:1

0<

MOV

0008

END