Required equipment and software, Example ladder logic program – Rockwell Automation 1203-CN1 ControlNet Communications Module 1203-CN1 User Manual

Page 63

Publication 1203-5.13 – February, 2002

PLC Ladder Logic Programming

5-3

Required Equipment and Software

Before creating a PLC ladder logic program, your PC should be:

•

Running RSLogix5 and RSLinx applications. Refer to

http://www.software.rockwell.com for more information on these

products.

•

Connected to and communicating with the ControlNet network

using a 1784-KTCX card, 1784-PCC card or 1770-KFC adapter.

Example Ladder Logic Program

The following is an example ladder logic program for a 1305 drive or

a 1336 PLUS drive.

Important: Consult your SCANport product’s user manual for I/O

patterns. Different SCANport products have different Logic

Command Data and Logic Status Data patterns.

The 1305 or 1336 PLUS drive in this example accepts the following

Logic Command Data from the PLC.

!

ATTENTION: The example ladder logic program

shown in this manual is intended solely for purpose

of example. Because there are many variables and

requirements associated with any particular

installation, Rockwell Automation does not assume

responsibility or liability (to include intellectual

property liability) for actual use based upon the

example shown in this publication.

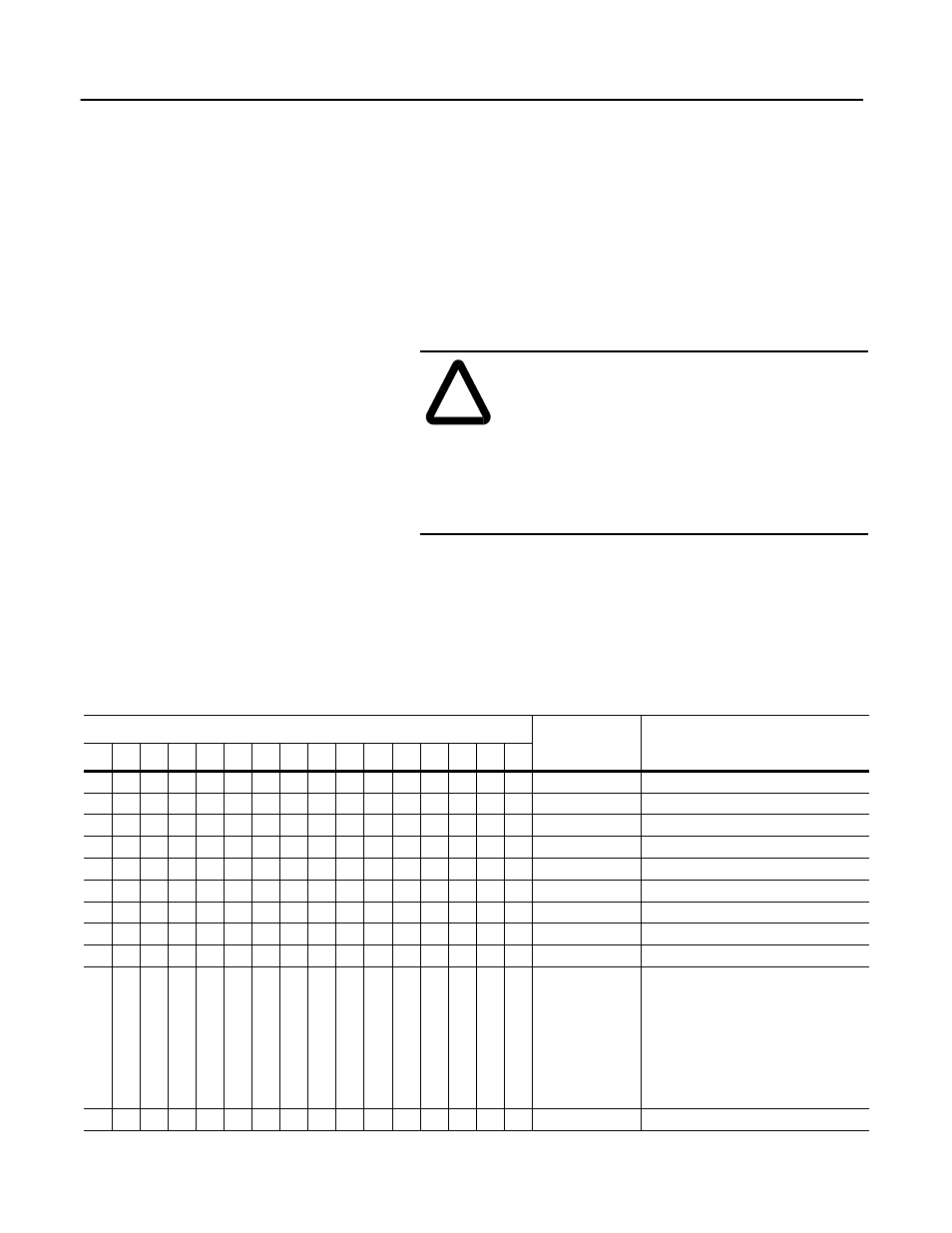

Logic Status Bits

Function

Description

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

X Stop

1=Stop, 0=No Operation

X

Start

1=Start, 0=No Operation

X

Jog

1=Jog, 0=No Operation

X

Clear Faults

1=Clear, 0=No Operation

X

X

Direction

00=No Operation, 01=Forward, 10=Reverse

X

Local

1=Local, 0=Multiplexed

X

MOP Increment

1=Increment MOP, 0=No Operation

X

X

Accel Rate Select

00=No Operation, 01=Rate 1, 10=Rate 2

X

X

Decel Rate Select

00=No Operation, 01=Rate 1, 10=Rate 2

X

X

X

Reference Selection 000=No Operation

001=External Reference 1 (Par 5)

010=External Reference 2 (Par 6)

011=Preset 3

100=Preset 4

101=Preset 5

110=Preset 6

111=Preset 7

X

MOP Decrement

1=Decrement MOP, 0=No Operation