Seam-loc 24, Caution – Metal Sales Seam-Loc 24 Installation User Manual

Page 53

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Office) • www.metalsales.us.com

52

SEAM-LOC 24

®

INSTALLATION NOTES

S

CULPTURED

G

UTTER

O

VER

R

IGID

I

NSULATION

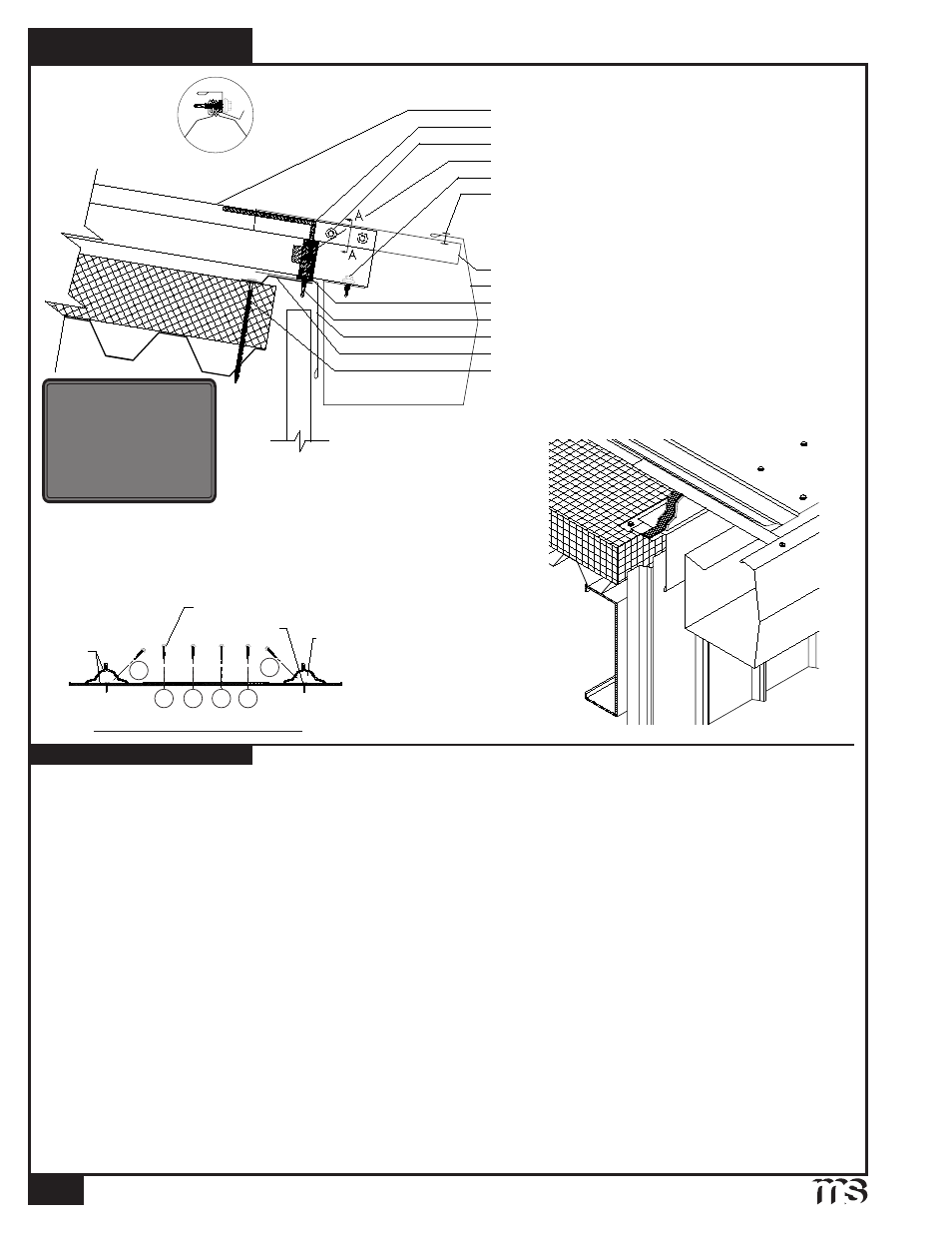

#12-14 x 1

1

/

2

" Self Driller XL (2 per gutter support)

1

/

8

x

13

/

16

" Pop Rivet (1 per gutter support)

Gutter Support (located at every rib)

Double Bead Tape Sealant

Seam-Loc 24 Panel

Gutter Drip

Eave Plate

Seam-Loc 24 Sculptured Gutter

#

1

/

4

-14 x

7

/

8

" Stitch Screw XL (2 per panel)

#12-14 x 1" Self Driller N/W (see below)

Tube Sealant

A - A

1

/

4

:12 Slope

Minimum

Seam-Loc 24 Fastening Pattern

D. B. T. S.

#12-14 x 1" SD N/W

Metal

Inside

Closure

#12-14 x 1

1

/

4

" SD XL

2

6

5

4

1

3

CAUTION

In locations where heavy

rainfall or severe ice and

snow may occur, Metal Sales'

standard gutters may not be

suitable for use.

#14-13 x (X") Dekfast (1'-0" o.c.)

Seam-Loc 24 Metal Inside Closure (see below)

Note: Lengths of Dekfast screws are

dependent on the assembly thickness

(see page 17 for lengths).

Gutter Drip Flashings must be installed prior to panel installation.

1. Install Gutter Drip back against previously installed Eave Plate, (see page 25 for Eave Plate installation). To hold Gutter

Drip in place fasten to substrate with #10-16 x 1" Pancake Head fastener, 4'-0"o.c.

2. Apply a row of Double Bead Tape Sealant across Gutter Drip so that sealant is centered over top leg of Eave Plate.

3. If two or more flashings are required, lap the flashing over the previously installed flashing by a minimum of 2"

placing a bead of Tube Sealant between the flashings and securing with Pop Rivets, 2

1

/

2

"

4. Once panels and inside closures have been installed and properly sealed, (see page 26), fasten through panel, Double

Bead Tape Sealant, and Gutter Drip into Eave Plate with (6) #12-14 x 1

1

/

4

" Self Driller XL screws per panel.

5. Attach the SSR Gutter Support to the panel rib every other panel (48"o.c.) with (2) #12-14 x 1

1

/

4

" Self Driller XL

screws. Fasteners must be applied down slope of the sealant line. Do not apply screws up slope of the sealant line. The

SSR Gutter Supports can be adjusted in or out to allow the gutter to be installed in a straight line, even if the edge of the

roof is not straight.

6. Prepare the first gutter section with a Sculptured Gutter End. Consider rake to gutter connection for proper placement of

Sculptured Gutter End and the gutter flashing. Fasten with (8) #

1

/

4

-14x

7

/

8

" Stitch XL screws or Pop Rivets.

7. Position the gutter over the SSR Gutter Supports with one end against the Rake flashing and rotate gutter into position.

8. Clamp the top of the back lip of the gutter in position with a C-clamp. Install a #

1

/

4

-14 x

7

/

8

" Stitch XL screw or Pop

Rivet where the front lip of the gutter rests on the SSR Gutter Support, and fasten the back lip of the gutter to the panel

flat with (2) #

1

/

4

-14 x

7

/

8

" Stitch XL screw per panel.

9. Field miter the rake trim to fit the gutter contour at the corner of the building or install a SSR Sculptured Corner Box.

10. If two or more flashings are required, lap the flashing over the previously installed flashing by a minimum of 2" placing a

bead of Tube Sealant between the flashings and securing with #

1

/

4

-14 x

7

/

8

" Stitch XL screws or Pop Rivets, 2

1

/

2

" o.c.