Step 6, Seam-loc 24 – Metal Sales Seam-Loc 24 Installation User Manual

Page 31

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Office) • www.metalsales.us.com

30

SEAM-LOC 24

®

Seam-Loc 24

Peak Panel

Pull up panel

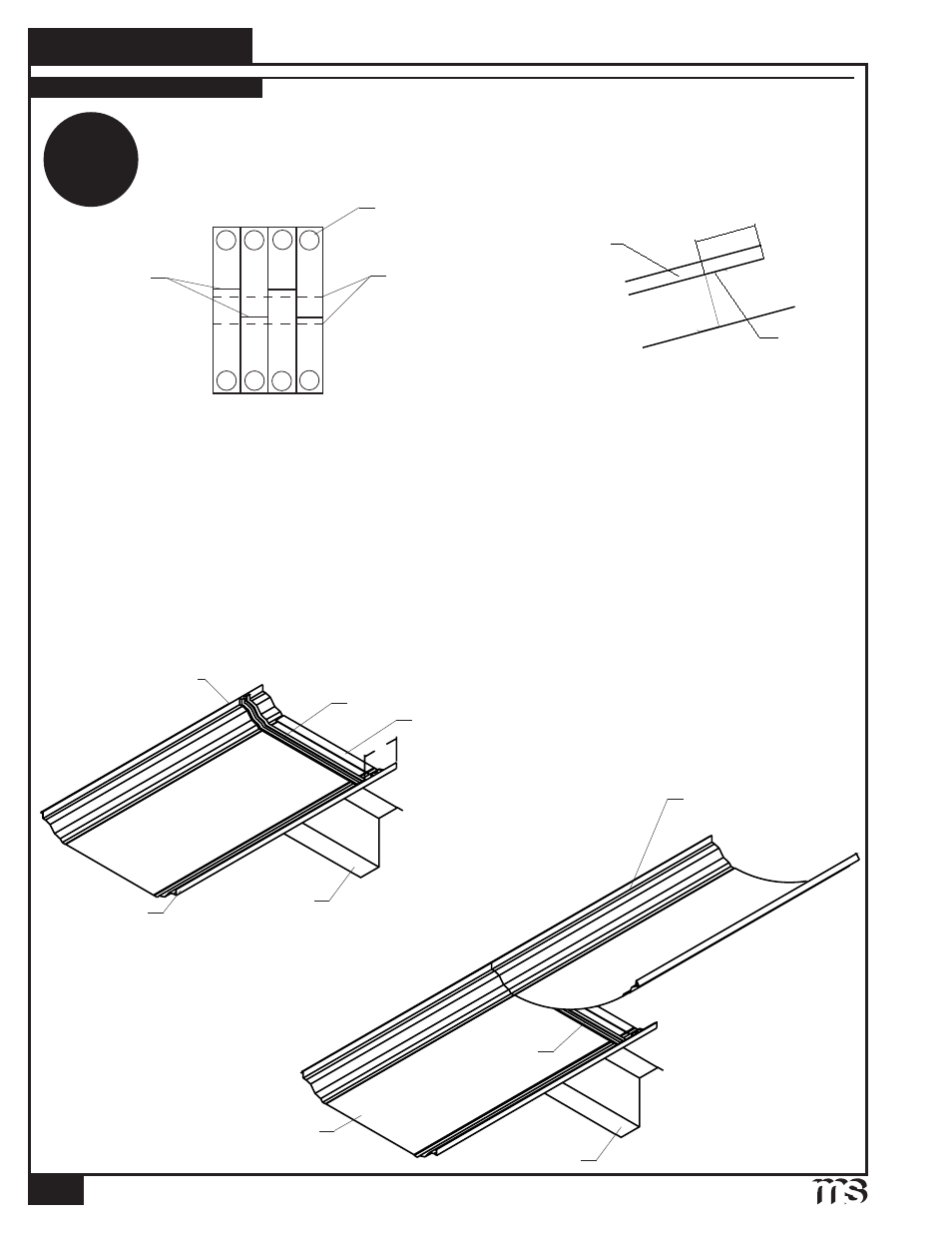

Endlap

Pad

Note: It is critical that purlins at the ridge and endlap be exactly located as detailed on construction

drawings. Panels with endlaps must be fixed at the eave. Endlap splices are to be staggered as shown.

The following procedures also apply to panel runs with multiple laps.

Steps:

ENDLAPPING OF PANEL

6" or 9"

Endlap

Purlin

Seam-Loc 24

Panel

STEP

6

End of factory notch

Seam-Loc 24

Eave Panel

Endlap Sealant

Endlap Purlin

I

NSTALLATION

OF

P

ANEL

(

CONT

.)

1. The installed eave panel should measure 6" or 9" from the web of the endlap purlin to the end of the

eave panel. (6" for panels produced in Longmont, CO / 9" for panels produced at all other

branches) This dimension must be verified. If the panel exceeds this, verify that the eave overhang

dimension is correct.

2. Slide Compression Plate under panel in center of endlap and cee clamp to panel to hold in place for

attachment.

3. The male and female legs of the high end of the eave panel are factory notched to allow the peak panel

to nest inside the eave panel.

4. Apply Endlap Pad on the notched end of the eave panel down male leg, across panel flat, and up the female

leg 1⁄2" to 3⁄4" from the end of the panel.

5. Lap the female leg of the peak panel into the female leg of the eave panel lapping the proper 3" or 6".

Eave

Peak

Staggered Endlapping

Endlap Purlins

Panel Installation Sequence

1

2

4

6

8

3

5

7

Panel Endlaps

Compression Plate

Endlap Purlin

Seam-Loc 24

Eave Panel

3" or 6" Lap