Step 2, Seam-loc 24 – Metal Sales Seam-Loc 24 Installation User Manual

Page 26

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Office) • www.metalsales.us.com

25

SEAM-LOC 24

®

STEP

2

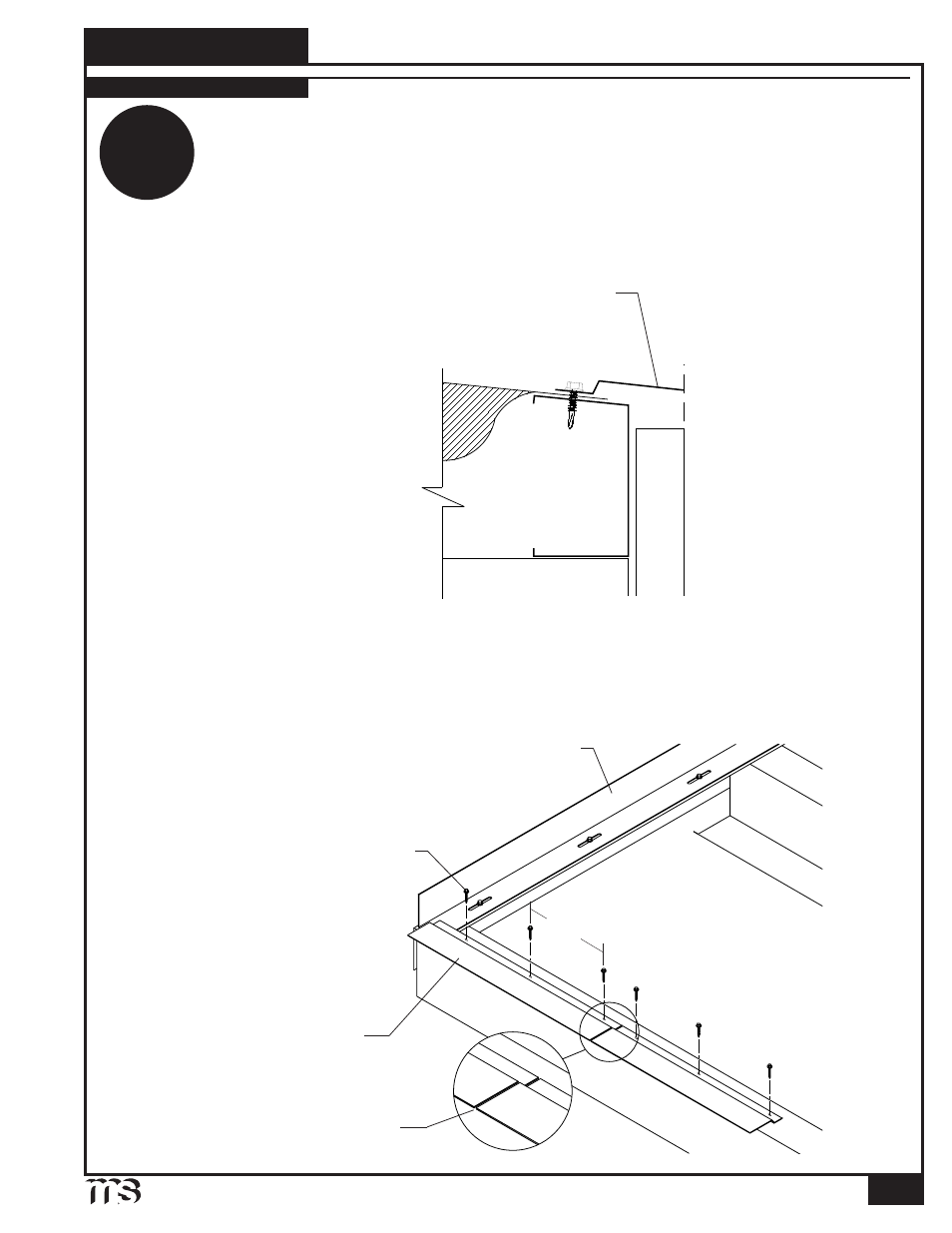

Note: The Eave Plate serves as an extension of the structure to support and fasten the panel at the eave

and valley on applications utilizing the Low, Mid, or High Floating Clip Systems. Size of Eave Plate can

vary, (see System Components list on page 20).

Steps:

1. If using blanket insulation, the Eave Plate may be used to secure the insulation at the eave. Be sure to remove

the fiberglass and fasten only the vapor barrier to avoid wicking.

2. Place pre-punched leg of Eave Plate on top of eave framing member. Align the top leg of the Eave Plate

flush with the finished wall surface at the eave of the building.

Align Eave Plate With

Finished Wall Surface

I

NSTALLATION

OF

P

ANEL

(

CONT

.)

3. Fasten Eave Plate to eave framing member with #12 -14 x 1" Self Driller No Washer screws 1'0" o.c.

Do not fasten through Eave Plate into Floating Rake Angle. Movement of the Floating Rake Angle is

imperative for proper installation of roof system.

4. If two or more Eave Plates are required, butt ends of the Eave Plates (Do Not Overlap) and continue

fastening.

INSTALLING EAVE PLATE

Floating Rake Angle

Eave Plate

Butt ends

Self Driller no Washer

1'-0"