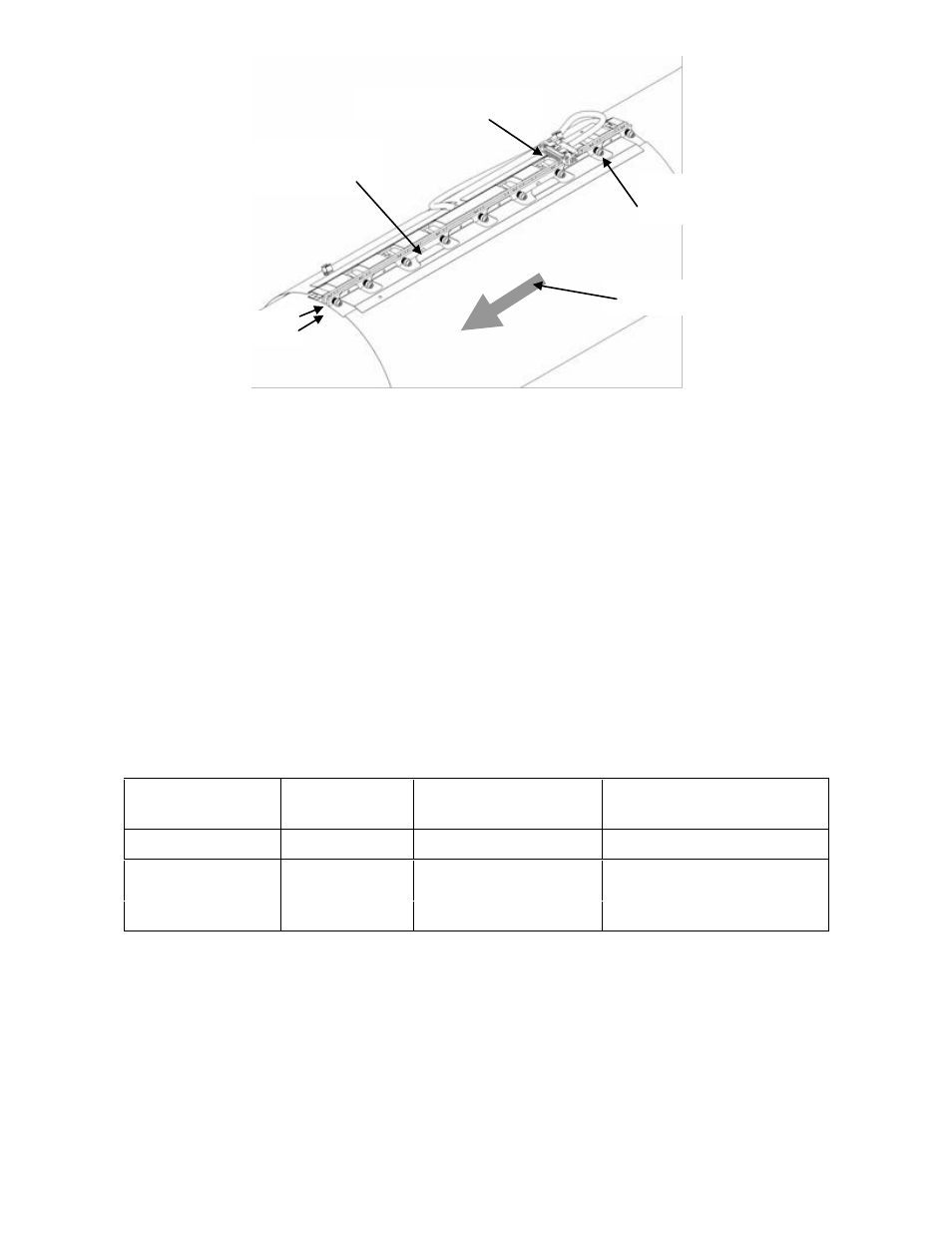

Figure 1, Sensor band screw and alignment pins -9, Table 4 – CiDRA SONARtrac PW VF-100 User Manual

Page 27: Gauge block and screw size -9

20831-01 Rev 05

Page 5-9

Figure 1

Sensor Band Screw and Alignment Pins

Wrap the sensor band around the pipe and slide the alignment pins on

the attachment rail through their mating holes on the opposite

attachment rail. If the process pipe has a welded seam, align the gap

between the sensor attachment rails along the pipe weld seam. Final

positioning can be made after the sensor screws have been started.

Note: When installing the sensor band keep in mind the requirement

for transmitter connector socket assembly orientation as described in

Section 5.7. If necessary, due to cover installation constraints, wrap

the sensor band over the weld seam.

Carefully start threading the screws into their screw holes (avoid cross

threading) by using the hex driver until each screw is engaged about 2

turns. Once all screws are engaged make final positioning of the

sensor assembly with respect to pipe weld seam or desired orientation

on the pipe. The following table provides guidance for selecting the

proper hex tool and spacer gauge.

Table 4

Gauge Block and Screw Size

Sensor Band P/N

Spacer Gauge

P/N

Socket Head Screw

Hex Size (inch)

Band Attachment Rail

Size (Ref)

20380- ALL SIZES

20143-01

7/64

1/8 x 3/8

20409- ALL SIZES

20143-02

7/64

1/8 x 3/8

20686- ALL SIZES

20143-04

5/32

1/4 x 1/2

Sensor attachment screw

assembly (typical 9 places)

Alignment pins

(typical 2 places)

Flow direction arrow

Attachment rails

Sensor band shorting plug