Hmt315 for high temperatures, Figure 10, Marking the nut – Vaisala HMT310 User Manual

Page 29

Chapter 3 ________________________________________________________________ Installation

VAISALA ________________________________________________________________________ 29

4.

Mark both the fitting screw and the nut hex.

5.

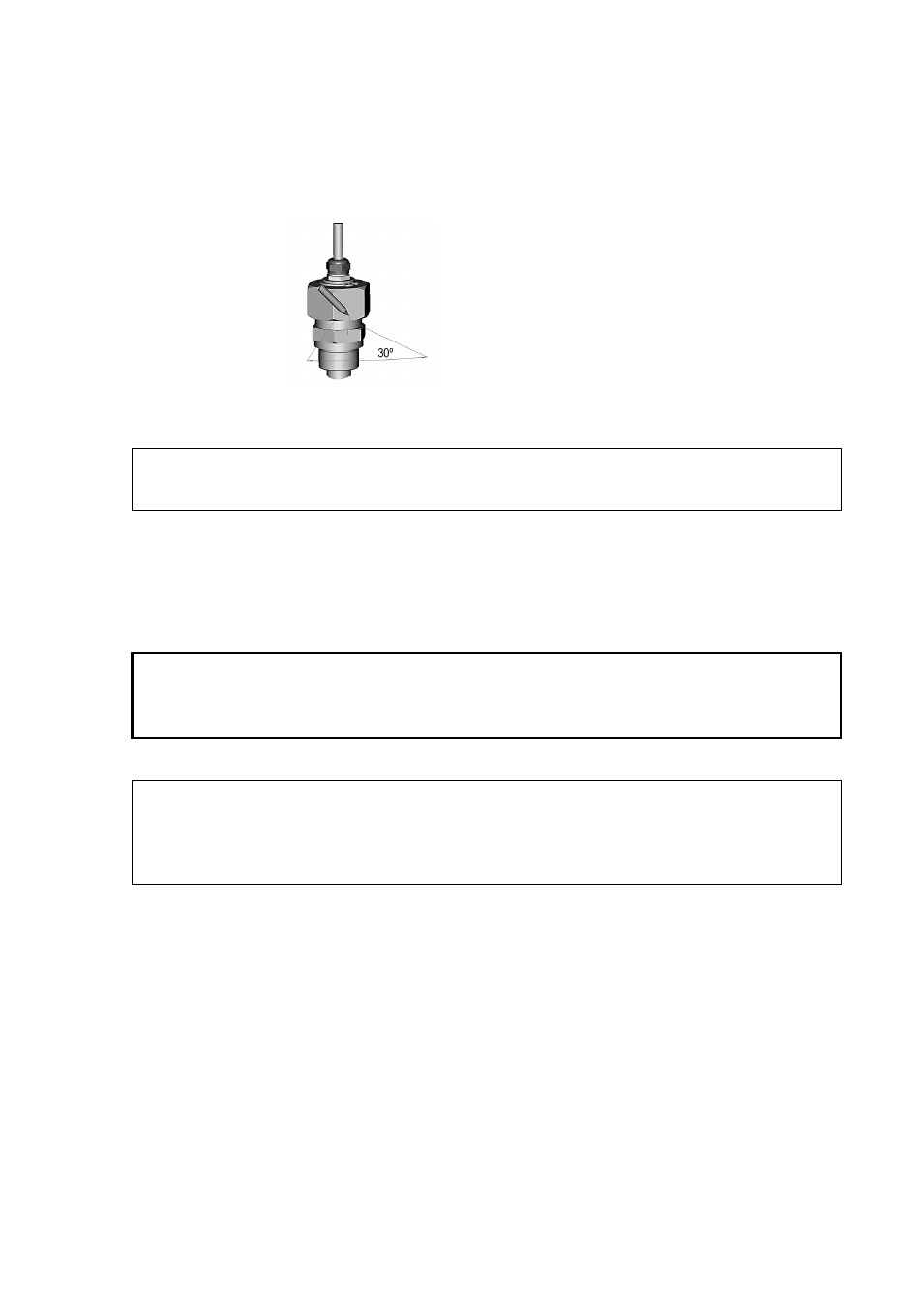

Tighten the nut a further 30° (1/12 turn) or if you have a torque

wrench tighten it with a torque of 80 ± 10 Nm (60 ± 7 ft-lbs).

0505-273

Figure 10

Marking the Nut

NOTE

When re-tightening the nut after detachment the nut must be tightened

without increased effort.

6.

Clean and grease the tightening cone of the fitting screw after every

tenth detachment. Change the sealing washer every time the fitting

screw is detached. Use high-vacuum grease (for example; Down

Corning, Europe) or a similar grease.

See also section Measuring at Overpressure, on page 21.

CAUTION

In pressurized processes it is essential to tighten the supporting nuts and

screws very carefully to prevent loosening of the probe by the action of

pressure.

NOTE

When HMT314 is installed in a process with pressure differing from

normal atmospheric pressure, enter the pressure value of the process (in

hPa or mbar) into the transmitter memory via the serial line (see Set

Ambient Pressure for Calculations on page 51).

HMT315 for High Temperatures

HMT315 is installed similarly than the HMT313 probe but without the

supporting bar. Refer to Appendix A on page 99 for more information on

the duct installation kit for HMT315.

To avoid incorrect humidity readings, the temperature differences

between inside and outside of the duct must not be remarkable.