Otton, Roubleshooting, Able – Ag Leader InSight Cotton Harvest Insert Ver.6.0 Users Manual User Manual

Page 54: Continued

InSight™

User Guide - Cotton Harvest Insert

626

PN: 2002881 Rev.F

C

OTTON

T

ROUBLESHOOTING

T

ABLE

(

CONTINUED

)

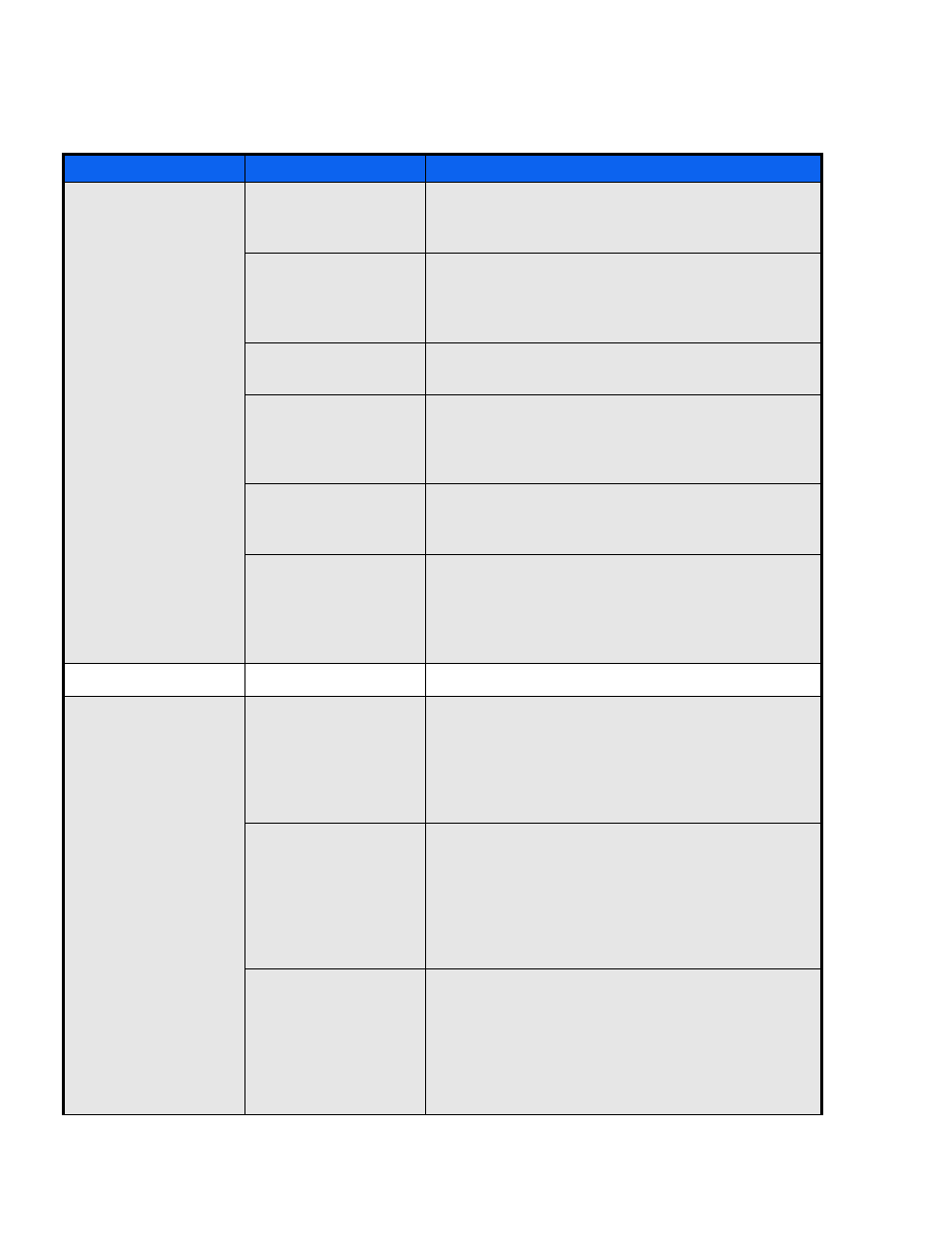

Problem

Possible Cause

Solution

The InSight monitor

is displaying

inaccurate yields (all

picker models).

Calibration was not

performed properly.

Check calibration loads to ensure that a minimum

of three loads were recorded and have an average

error below 5% and a maximum error below 10%.

Speed reading is

inaccurate.

If using GPS as your ground speed source, check the

signal to ensure that the InSight monitor is getting

DGPS. If using a ground speed sensor, perform a

ground speed calibration to verify speed accuracy.

Area count is not

correct.

See the Incorrect Area Count problem and solution

described under

“Incorrect area count.” on page 627

Cotton may snag on

loose or jagged

edges and give false

readings.

Remove any stringers. After installation, file any

jagged edges below the sensors or seal the edges

for a smooth finished edge.

Excess light in chutes.

Make sure the chutes are sealed properly and that

excess light is not reflecting into the chutes which

can cause false readings.

Change in field

conditions.

If a field condition change leads to incorrect yield

values, a new calibration may be needed to

continue recording accurate values. For more

information about retiring calibrations, see

“Adding a New Calibration” on page 605

.

Monitor displaying

zero flow or zero

yield.

(see also following

page).

Fan speed is not

above 2500 RPM or

below 4000 RPM.

Verify that the fan speed is above 2500 RPM and

below 4000 RPM. If the speed is above or below

this value, no yield will be recorded. For further

troubleshooting tips, see

low (RPM must be between 2400 and 4000).” on

page 627

Module is not

communicating

properly.

Check the module communication by going to the

Run screen and selecting the System button in the

upper right-hand corner. Select the CAN Tab and

verify that the speed module and all cotton flow

modules are detected in the CAN device list. If a

module is not shown on the list, then check the

modules to see if their indicator lights are flashing.

Modules are not on

correct firmware.

Check the firmware for modules by going to the

Run screen on the InSight monitor and selecting

the System button and CAN Tab. Make sure all the

modules and the InSight monitor itself are all on

the correct firmware. The current firmware is

available on the InSight Support web page at

www.agleader.com.