KROHNE ALTOSONIC V EN User Manual

Page 99

ALTOSONIC V

Operating Manual rev02 E

7.30850.34.00

Page 99 of 106

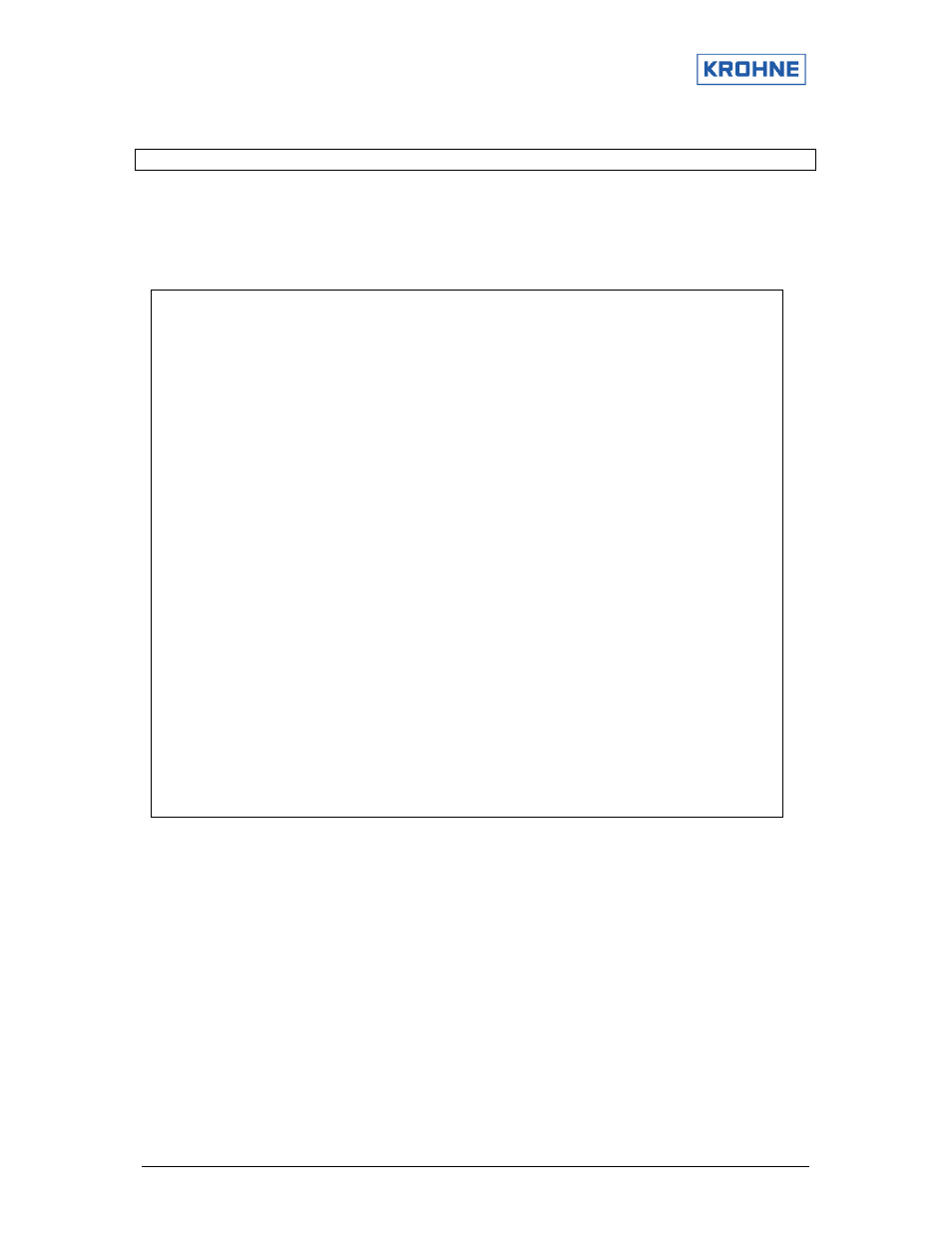

10.4.3 Measurement alarms batch validation error values input

Depending on the application the batch validation error values can be changed.

For example if the temperature input can not differ more from the measured value than for example

100°C, than the validation error on that input can be changed to 10% of 25% (250°C difference).

Also the weighing method as described in chapter 6 can be changed.

CLNT0300.DAT excerpt

21 [BATCH VALIDITY PERCENTAGES]

The following percentages [0..100] are used (if batching is enabled) to

calculate if the batch has an acceptable error volume.

(Worst case batch volume error calculation in relation to the total

batch volume for all occured errors.)

See the Altosonic-V Operator manual for a more detailed explanation of

the calculation being utilized for this.

Discuss/verify the batch error percentage (21.16) with you local DTI!

21.01 Weight (%) for Temperture Body

c=#1.00

21.02 Weight (%) for Temperture Process

c=#25.00

21.03 Weight (%) for Temperture External

c=#25.00

21.04 Weight (%) for Temperture Density

c=#25.00

21.05 Weight (%) for Pressure Process

c=#2.50

21.06 Weight (%) for Pressure External

c=#2.50

21.07 Weight (%) for Pressure Density

c=#2.50

21.08 Weight (%) for Density

c=#100.00

21.09 Weight (%) for Density Standard

c=#100.00

21.10 Weight (%) for Viscosity

c=#7.00

21.11 Weight (%) for 1-4 channels down

c=#0.50

21.12 Weight (%) for All channels down

c=#100.00

21.13 Weight (%) for API group mismatch

c=#100.00

21.14 Weight (%) for System Alarms

c=#10.00

21.15 Weight (%) for RealTimeProfiel OOR

c=#3.50

21.16 Weight (%) for allowed batch error

c=#0.06

21.17 Method of weighing

c=#2 //1=Weighing on Max Flow only

//2=Weighing on Actual Flow when

// possible