KROHNE ALTOSONIC V EN User Manual

Page 77

ALTOSONIC V

Operating Manual rev02 E

7.30850.34.00

Page 77 of 106

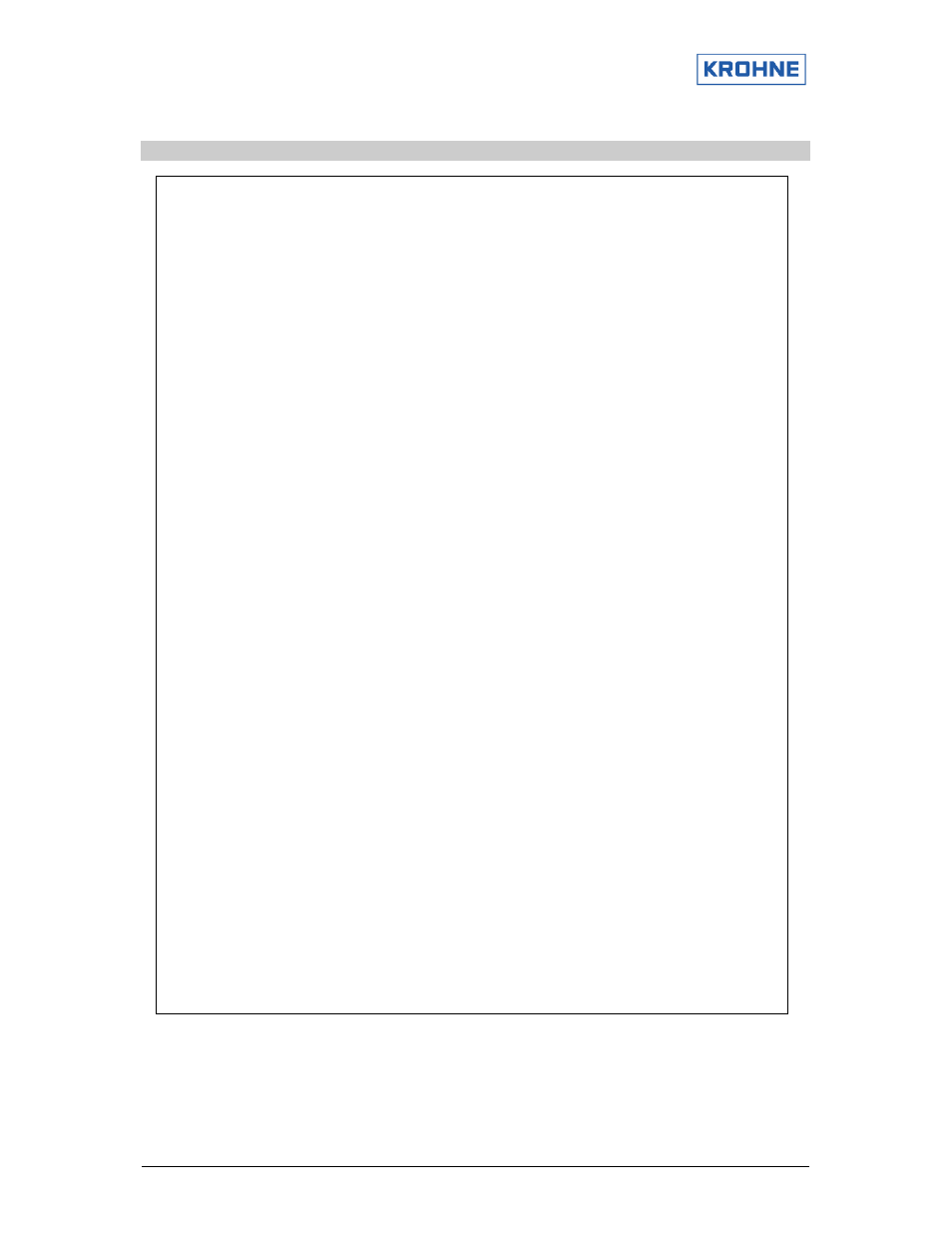

6.13 Example of ticket to output:

The alarms on Temperature Proces and Pressure Proces caused a deviation on the Standard

Volumes that will be larger then 0.06% therefore the batch is declared not valid.

The produced ticket has an incorporated crc checksum that is checked every time the ticket is

retrieved from memory to read/print. If this check fails, this is clearly stated on the ticket as ticket Not

valid due to crc checksum fail

DECISIVE PRESENTATION: NOT VALID, SYSTEM ERRORS DURING BATCH

KROHNE Altometer

IDENTIFICATION

Ticket number : 3

Start time : May 21 18:34:46 2001

Stop time : May 21 18:51:46 2001

Serial number : 98843901

Software version: 03.00.00

Tag number ID : F2501

Batch ID : Crude oil23

Batch name : Tank56C

TOTALISERS

Proces[m3] Standard[m3] Mass[tonM]

Start Cum.: 731.60 747.43 485.83

Stop Cum.: 757.43 773.82 502.99

Batch : 25.83 26.39 17.15

BATCH FLOW WEIGHTED AVERAGES

Temperature[°C] Pressure[bar] Density [kg/m3]

Proces : 0.00 0.00 664.072

Densito meter: 0.00 0.00 500.000

Standard : 15.00 650.000

CONFIGURATION ON STANDARD VOLUME CALCULATION

Calculation Method : API2540

Temperature standard [°C]: 15.00

Density standard by : Manually

Api group fluid type : Crude

API correction factor K0 : 613.9723

API correction factor K1 : 0.0000

API correction factor K2 : 0.00000000

ALARMS Measured[s] Override[s]

Temperature Body : 0.0 0.0

Temperature Proces : 51.7 0.0

Temperature Densitometer : 0.0 0.0

Pressure Proces : 51.7 0.0

Pressure Densitometer : 0.0 0.0

Density Proces : 0.0 0.0

Density Standard : 0.0 0.0

General Flow 1-4 channels down : 0.0

General Flow all channels down : 0.0

Calculation API group mismatch : 0.0

System runtime alarms occurred : 0.0

Realtime Profile out of range : 0.0

ERROR IN BATCH BY:

-during batch: measurement alarms possibly cause > 0.06 percent deviation

CRC-CHECKSUMS:EXE00000 UFS35374 UFP04625 DAT53611 TICxxxxx