KROHNE ALTOSONIC V EN User Manual

Page 55

ALTOSONIC V

Operating Manual rev02 E

7.30850.34.00

Page 55 of 106

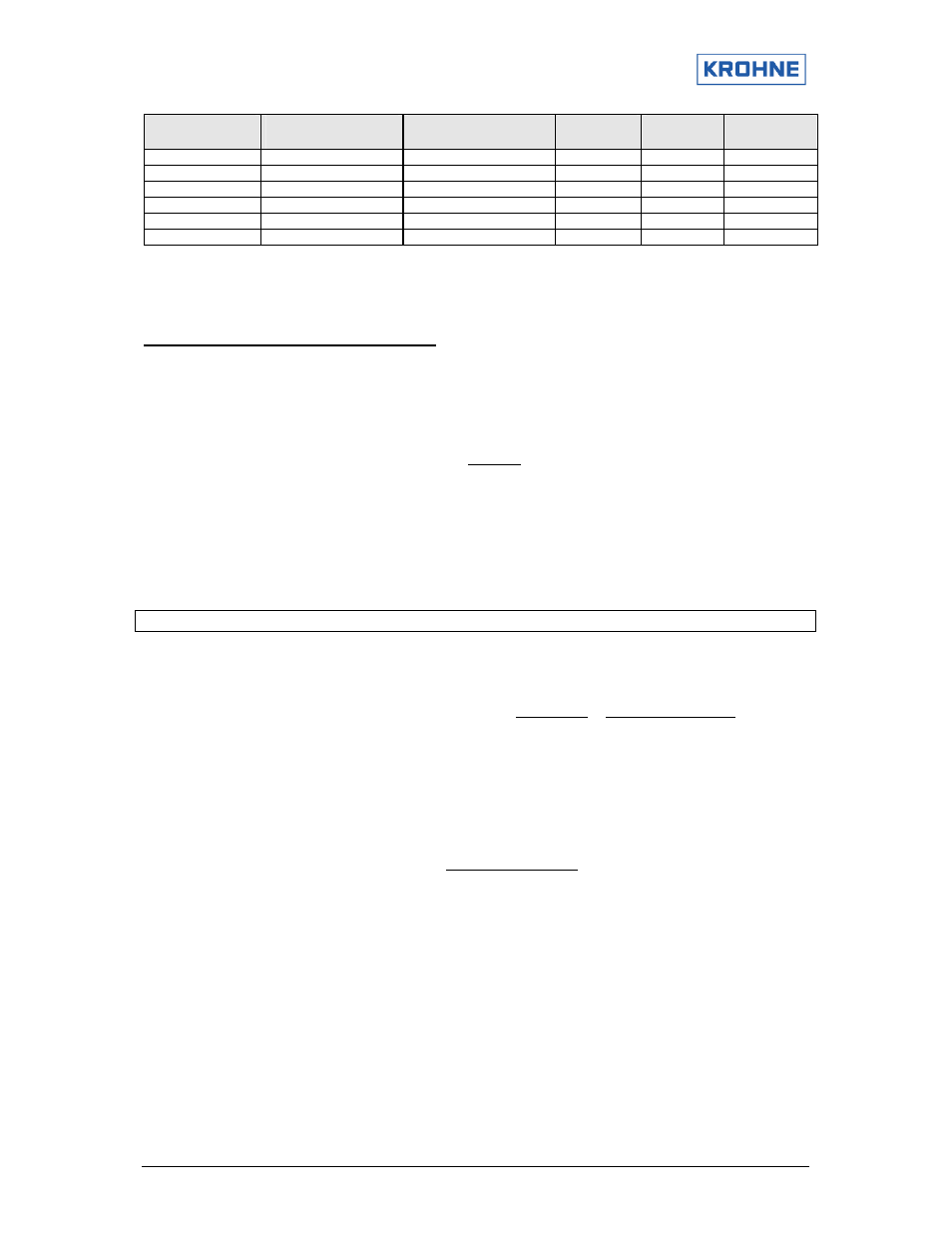

Type of product

Low limit

ρ

ρ

ρ

ρ

15

[kg/m3]

High limit

ρ

ρ

ρ

ρ

15

[kg/m3]

K

0

K

1

K

2

Crude

610.5

1075.0

613.9723

0

0

Gasoline

653.0

770.0

346.4228

0.4388

0

Trans.area

770.5

787.5

2680.3206

0

-0.00336312

Jet group

788.0

838.5

594.5418

0

0

Fuel oil

839.0

1075.0

186.9696

0.4862

0

Free fill in

500.0

2000.0

0

0

0

Practical rule: The correction per °C is approximately 0.05% - 0.15% depending on conditions and type

of product.

Standard temperature different from 15°C:

The method is based on a reference standard of 15°C. For example if the proces temperature is 65°C.

15

65→

=

tl

tl

C

C

If the required standard temperature is different from 15°C the correction for the difference is

introduced. For example if the standard temperature is 20°C,

15

20

15

65

→

→

=

tl

tl

tl

C

C

C

Note: If the standard temperature is different from 15°C the density limits per product type also

change. The UFP-V calculates the limitations for the installed standard temperature. A density can not

be filled in beyond limitations. The Free Fill product type is for uncommon products, K0, K1 K2 are

adjustable.

5.1.2

Calculation of correction pressure dependency C

pl

The basic mathematical model, used to develop this standard, relates the compressibility factor

exponentially to temperature and the square of the molecular volume. That is:

]

10

0042092

.

0

10

87096

.

0

00021592

.

0

62080

.

1

[

6

2

15

6

2

15

−

−

⋅

⋅

+

⋅

+

⋅

+

−

=

ρ

ρ

process

process

T

T

EXP

F

F

: Compressibility factor, [1/kPa]

T

proces

: Temperature proces [°C]

ρ

15

: Density at 15 °C [kg/m

3

]

The compressibility factor F is used in the normal manner of volume correction to make the correction

for the pressure effect:

4

10

1

1

−

⋅

⋅

−

=

process

pl

P

F

C

C

pl

: Pressure correction factor

F

: Compressibility factor

P

proces

: Pressure proces [bar]

Practical rule: The correction per bar is approximately 0.005% - 0.015% depending on conditions and

product.