KROHNE ALTOSONIC V EN User Manual

Page 75

ALTOSONIC V

Operating Manual rev02 E

7.30850.34.00

Page 75 of 106

6.11.2 Measurement alarms batch validation

There are 2 methods for the batch validation:

1. Validation using the maximum flow. This is the method as used in previous versions of this

program. Using the maximum flow for validation has shown in practice that it can lead to

overrated Batch Error% values.

2. Validation using the current flow as long as the current flow is calculated. Since version

03.00.50.01.

The method is set in the CLNT0300.DAT file item: “21.17 Method of weighing”

6.11.2.1 Method 1 static maximum flow

To validate a batch when a measurement alarm has occurred over a period of time (Alarm in [s]) the

following calculation is used to validate the batch within a 0.04% error.

100

[%]

]

[

3600

]

/

3

[

]

3

[

_

Error

s

Alarm

h

m

MaxFlow

m

error

Volume

⋅

⋅

=

[%]

100

]

3

[

_

_

]

3

[

_

[%]

⋅

=

m

proces

Volume

Batch

m

error

Volume

Deviation

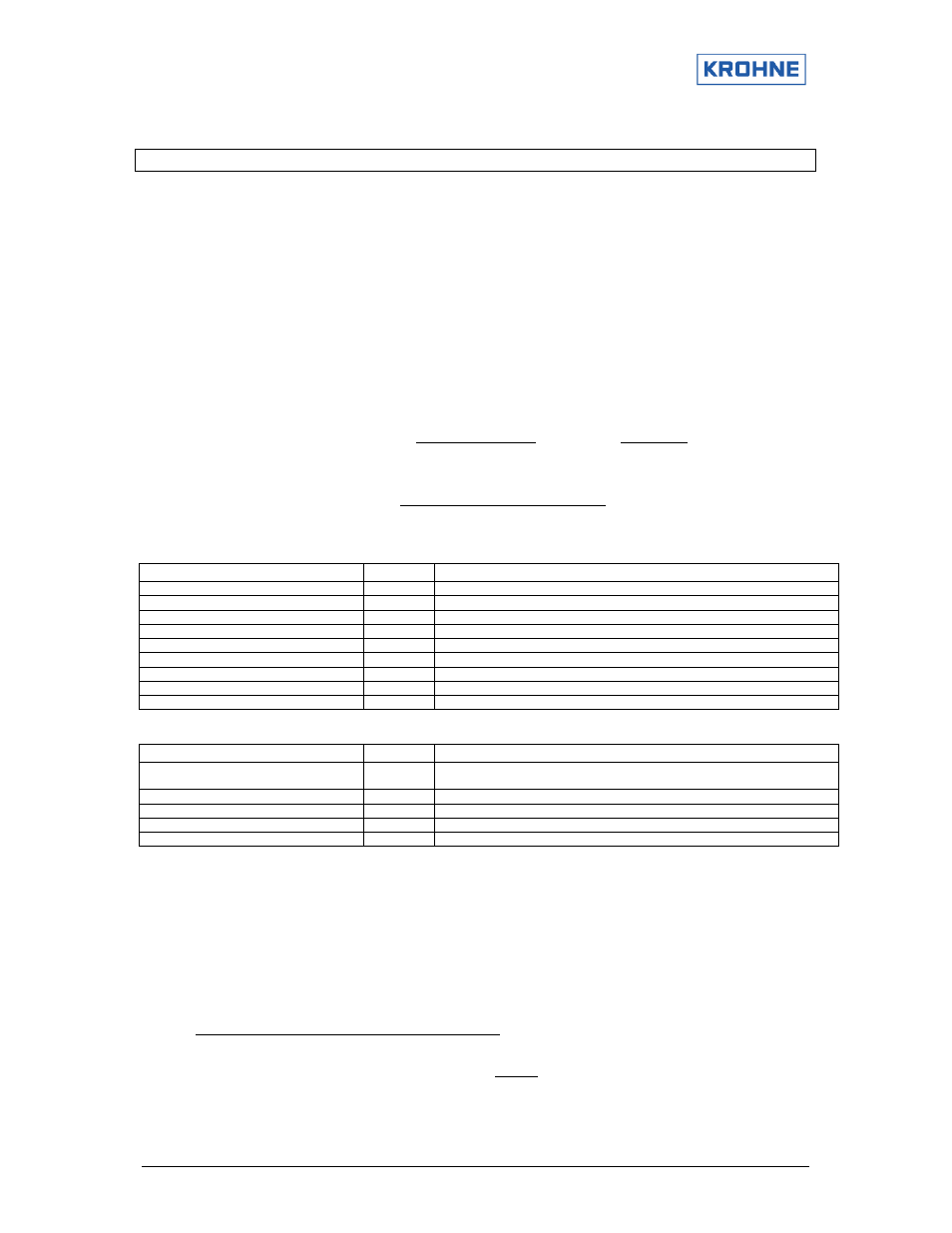

Secondary inputs measurement Error% on occurred alarm:

Secondary inputs

Error% Explanation

Temperature body

1

10°C is 0.036% deviation: 2% caused by >500°C

Temperature process

25

1°C is 0.1% deviation: 25% caused by 250°C deviation

Temperature proving external flow meter

25

1°C is 0.1% deviation: 25% caused by 250°C deviation

Temperature densito meter

25

1°C is 0.1% deviation: 25% caused by 250°C deviation

Pressure proces

2.5

1 bar is 0.01% deviation: 2.5% caused by 250 bar deviation

Pressure proving external flow meter

2.5

1 bar is 0.01% deviation: 2.5% caused by 250 bar deviation

Pressure densito meter

2.5

1 bar is 0.01% deviation: 2.5% caused by 250 bar deviation

Density densito meter

100

Standard volume correction uncertain therefore 100% errror

Density standard

100

Standard volume correction uncertain therefore 100% errror

UFP measurement Error% on occurred alarm:

Secondary inputs

Error% Explanation

1-4 channels down

0.5

Correction curve over viscosity never > 0.5%. (together with Real time

profile out of range error will lead to 4% error)

All channels down

100

System is not measuring flow therefore 100% error

API group mismatch

100

Standard volume correction uncertain therefore 100% errror

System alarms

10

Over estimated value on alarms as file not found, overrun etc

Real time profile out of range

3.50

Correction curve over viscosity never > 3.5%. To secure validity value=10%

Each alarm is measured in seconds, and the Volume_Error it causes, is calculated.

All Volume_error values are summated and the total deviation is calculated.

Example: How long may a certain error be active during a batch before the batch is Not Valid:

•

Only alarm 1-4 channels down: alarm time is x

•

Maximum flow rate is 1200m3/h

•

Batch time is 24 hours at 80% of the maximum flow rate

The batch volume in 24 hours at 80% flow rate:

]

3

[

23040

]

/

3

[

1200

100

[%]

80

]

[

24

]

3

[

Pr

_

_

m

h

m

h

m

oces

Volume

Batch

=

⋅

⋅

=