KROHNE ALTOSONIC V EN User Manual

Page 22

ALTOSONIC V

Operating Manual rev02 E

7.30850.34.00

Page 22 of 106

4.3

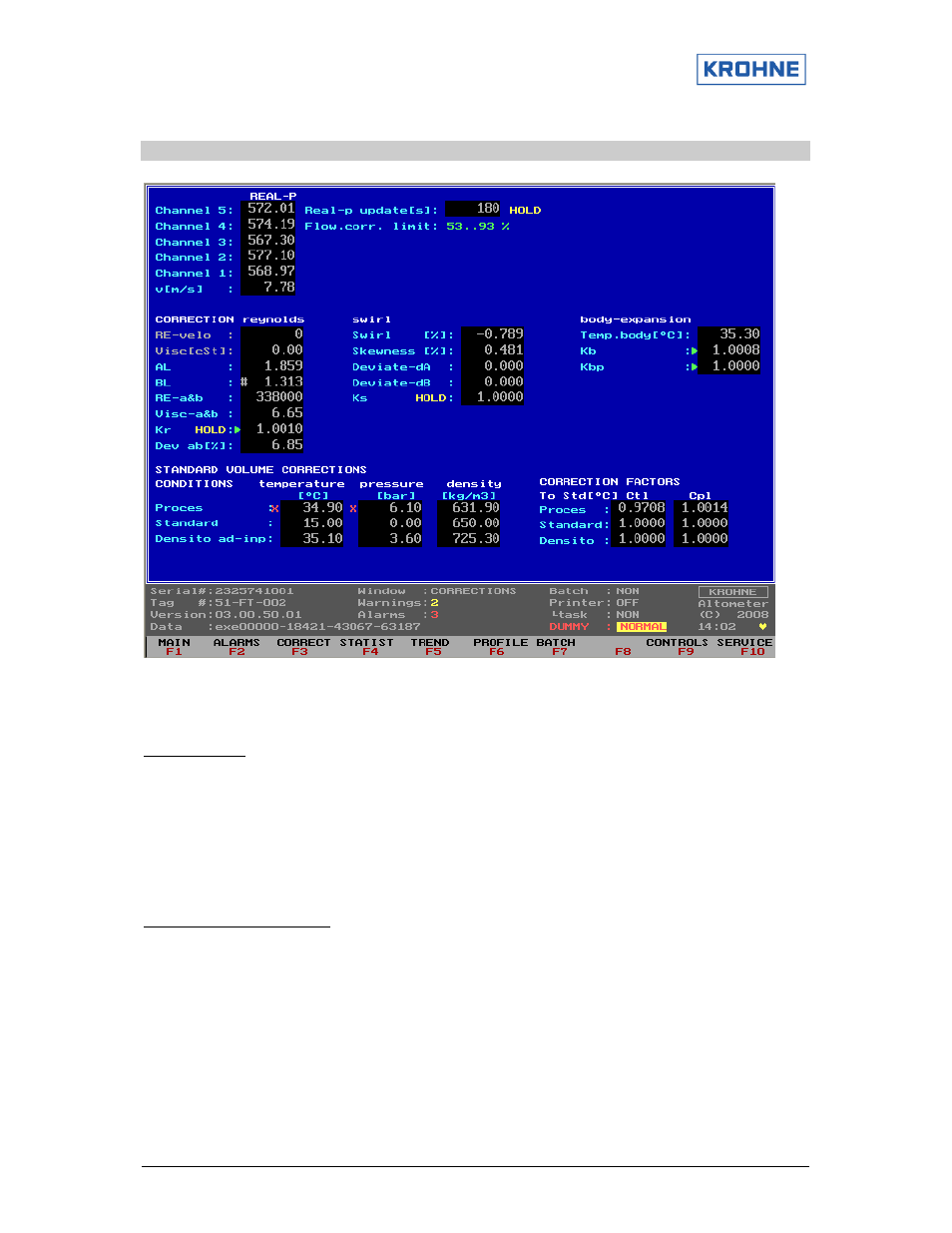

Main menu: F3 Corrections window

The Corrections window monitors the corrections.

Explanation of the Corrections window layout:

REAL-P shows:

•

The previously sampled profile.

•

The remaining update time to make the new REAL profile.

•

The sampling goes on hold if:

- Channel errors occur

- Less than 5% flow rate

This will show in yellow colour as HOLD.

•

The validity range in flow rate percentage of the sampled REAL profile. Out of this range an alarm

condition is activated

CORRECTION REYNOLDS:

There are three methods in using the Reynolds correction (method 1 is normally used).

1. Through ratio measured numbers AL and BL the profile belonging to a certain Reynolds Number

and its correction factor Kr is recognized in a calibrated lookup table. This the default used method

2. The kynematic viscosity is measured and the Reynolds number is calculated from F(Viscosity,

Diameter, Velocity). By a calibrated Reynolds table the correction factor Kr is found. Note that

Viscosity needs to be measured by the UFP or inputted by Modbus communication for this

method.

3. Input the Viscosity under reference conditions and the UFP corrects the viscosity for temperature

proces condition. Possible to have up to 6 liquids with choice by measured sound velocity.

This method is normally not used.

See the configuration file Reyn0300.ufs for further details.