1 quick start> 1-1, 1 quick start – Yokogawa Extractive Oxygen Gas Analyzer TDLS220 User Manual

Page 8

IM 11Y01B02-01E-A 4th Edition September 11, 2012-00

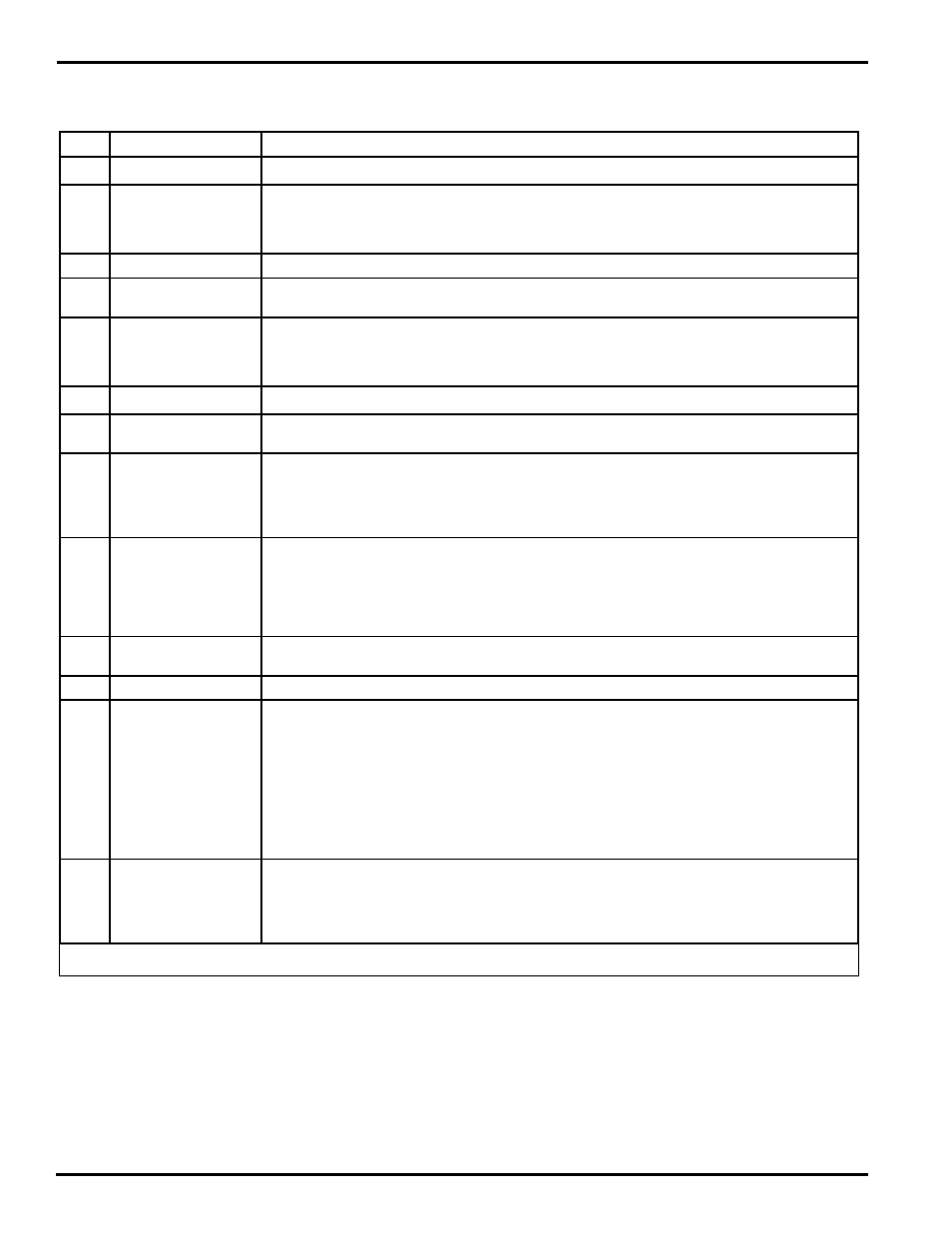

<1 QUICK START> 1-1

Step

Title

Description

1.0

Preparation

Carefully un-pack and check equipment for any obvious damage.

1.1

Ensure the appropriate utilities are available and ready for connection. These may include electri-

cal power, nitrogen purge gas, instrument air, validation gas, etc. Make sure the sample handling and

conditioning system meets the sample inlet and outlet requirements for TDLS220. Refer to Section XX

“Installation” for details.

1.2

Ensure you comply with any local and/or site specific safety requirements.

1.3

Read the appropriate sections of the Instruction Manual BEFORE starting any installation work – Contact

Yokogawa Laser Analysis Division or Local Agent if any doubts!

2.0

Installation

Ensure there is sufficient physical space to mount the analyzer and allow suitable space for any future

maintenance access. Mount the analyzer/panel to a secure vertical surface using appropriate style

shake-proof fasteners. Avoid areas prone to vibration to ensure long term reliability – the analytical mea-

surement itself is not affected by vibration.

3.0

Wiring

Ensure that all wiring will meet local codes and site requirements

3.1

Connect protective ground wire to the protective ground terminal of TDLS220. Use minimum 14 AWG

wire or equivalent.

3.2

Connect the appropriate single phase AC electrical power supply.

• 110/240 50/60 Hz to the terminal block located in the power/Temperature Controller box.

Refer to Part 2 (Electrical Hazard) of the “Safety” section in this manual. A suitable mains

disconnect device must be supplied. Refer to the “Installation” section of this manual for

details.

3.3

Check termination details before proceeding to prevent damage to electronics.

Connect any analog I/O signals to the optional analog I/O Board. Outputs land on TB8 and any pressure

inputs land on TB9.

Heated flow cells have the gas temperature signal already terminated at TB9.

A table of wiring terminations is included in this Instruction Manual

3.4

Connect any other equipment such as Ethernet, solenoid valves, digital I/O, etc. Note. Solenoids require

directional diode or ferrite coil on field wires at terminal block to prevent noise spikes.

3.5

Check terminations and ensure all cable shields are landed per supplied wiring details.

4.0

Utilities and

Sample

NOTE! – All purge, Validation Gas and other gas utility lines should be thoroughly cleaned, dried

and purged prior to connecting to the analyzer – Failure to do so can result in serious damage to

the TDLS220 or contamination to the internal optical elements resulting in poor performance

Connect the appropriate analyzer purge gas (nitrogen for oxygen analyzers) and make site connections

per the supplied purge gas sequence details (including any Hazardous area purge system). Start the

purge gas flow accordingly.

Some Oxygen analyzers may be capable of operating with Instrument Air purge alone or in conjunction

with Nitrogen purge of the measurement enclosure.

4.1

Connect process gas sample to the inlet port and the process sample return/vent to the flow cell outlet

port.

Ensure all inlet lines are clean and dry before connecting to prevent contamination of the flow cell and

flow cell window/mirror.

1 Quick Start