6 basic operation> 6-6 – Yokogawa Extractive Oxygen Gas Analyzer TDLS220 User Manual

Page 36

<6 BASIC OPERATION> 6-6

IM 11Y01B02-01E-A 4th Edition September 11, 2012-00

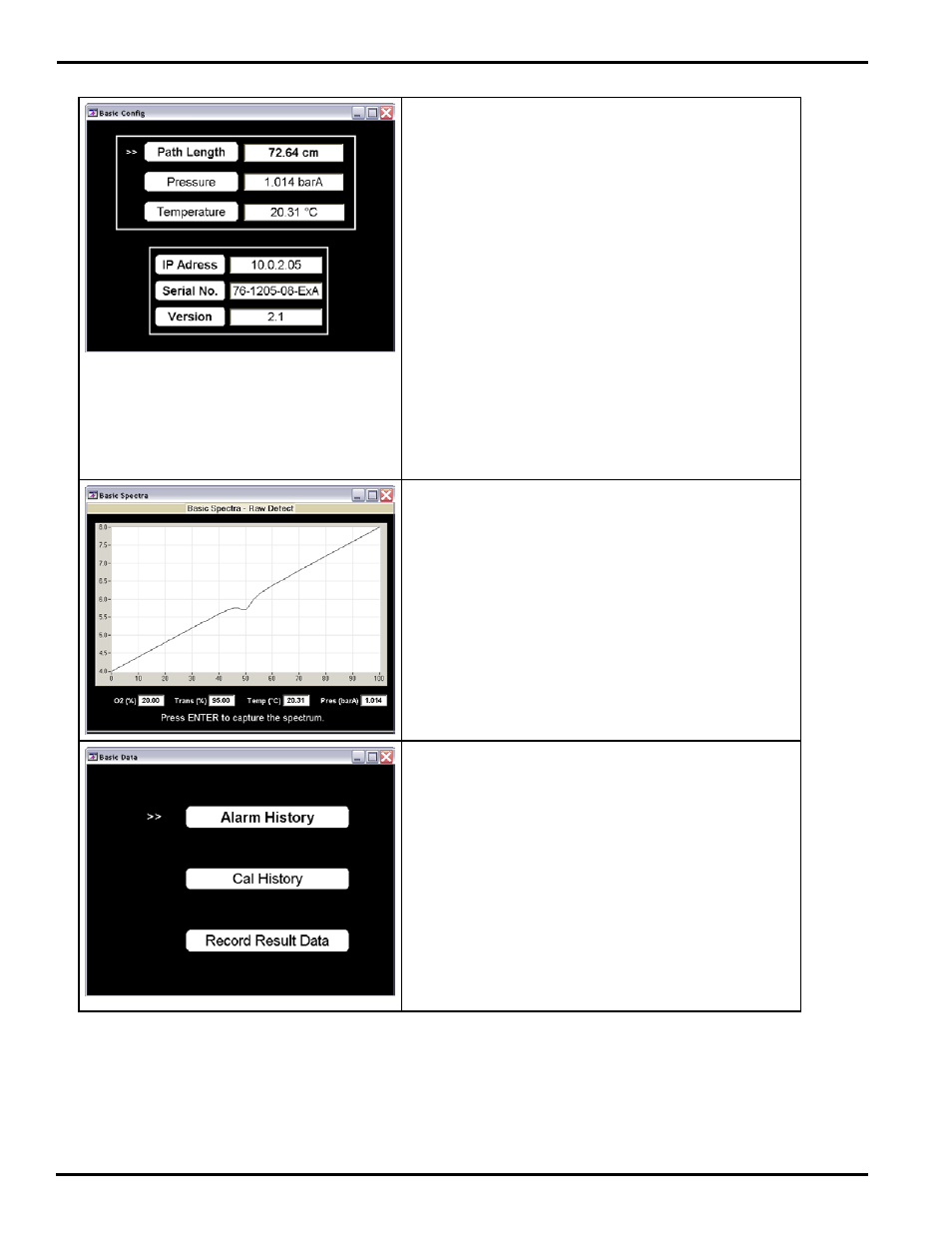

BASIC CONFIGURE

PATH LENGTH – Factory set, do not adjust. Typical

40” (distance the laser beam is exposed to the process

gas)

PRESSURE – allows adjustment of the gas pressure

value if using fixed pressure. If the analyzer is using

active pressure compensation, no changes are allowed.

Active pressure compensation settings are found in

Advanced Menu.

TEMPERATURE – allows adjustment of the gas

pressure value if using fixed pressure. If the analyzer

is using active temperature compensation, no changes

are allowed. Active temperature compensation settings

are found in Advanced Menu.

IP ADDRESS – displays the analyzer IP address

SERIAL NO. – displays analyzer serial number

VERSION – software version number

The spectra screen (raw detect or absorption) allow

capture and view of current spectra.

The screen auto scales the vertical axis, which will

result in a visually noisy absorption spectrum when at

low gas levels. In fact the spectra may not be noisy,

but simply that the display range is extremely low.

The BASIC DATA MENU allows the user to select:

ALARM HISTORY – displays the last 50 alarms and

faults with brief description, date and time

CALIBRATION HISTORY - displays the last 50

calibration events with adjustment amount, date and

time

RECORD RESULT DATA – The default setting during

normal operation is “User Data”. The system should

only be switched to “Factory Data” when advised by

Yokogawa Laser Analysis Division. Note: recording

Factory Data is only for specific diagnostic purposes

and should not be selected under normal operation.