5 installation and wiring> 5-5, Purge inlet n, Purge vent – Yokogawa Extractive Oxygen Gas Analyzer TDLS220 User Manual

Page 28

<5 INSTALLATION AND WIRING> 5-5

IM 11Y01B02-01E-A 4th Edition September 11, 2012-00

5.4 Purge Gas Requirements and Hazardous Area Systems

The TDLS220 Analyzer requires a continuous nitrogen (optionally instrument air) gas purge to prevent ambient

oxygen ingress to the optical path, when oxygen is the measured gas. The flow rate can be minimized as long

as it prevents any ambient oxygen ingress to the measurement optical path. Other purge gases may be used as

long as they do not contain any of the measured gas and a clean, dry, etc.

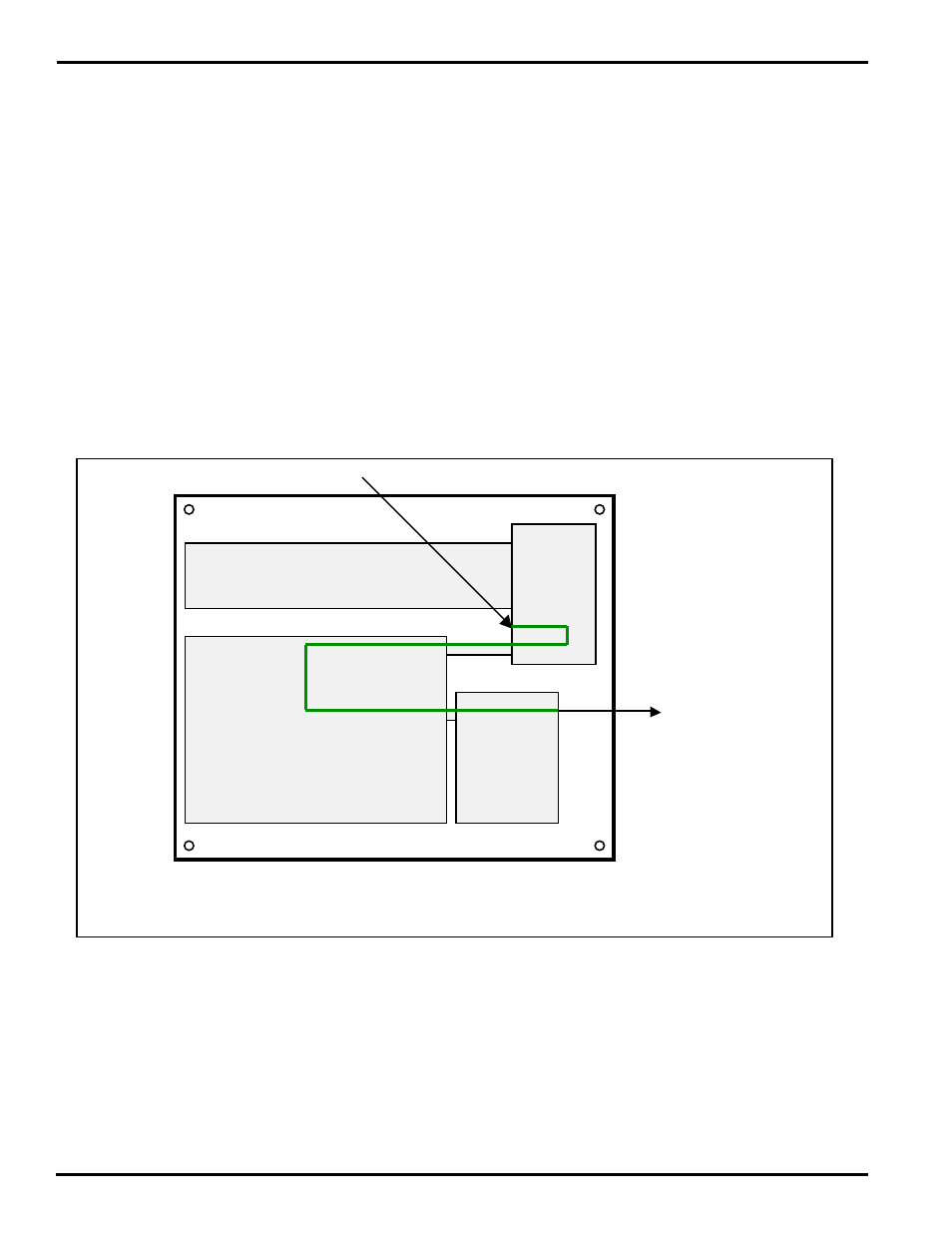

For hazardous area operation, the same nitrogen purge gas is used to purge the entire analyzer (including non-

optical path sections such as the electronics). Refer to purge diagrams below.

In some applications, Instrument Air (I/A) may be used as the purge gas. Special software configurations must

be set-up under the “Configure” section called “Non-Process Parameters” – refer to software section of this

manual for further details.

The flow rate can be minimized as long as it prevents any ambient oxygen ingress to the measurement optical

path. Other purge gases may be used as long as they do not contain any of

ELECTRONICS

CONTROLLER

FLOW CELL

POWER

HEAT

TRACE

LASER &

DETECT

N2 Purge Inlet

N2 Purge Vent

Figure 10 – Safe Area/General Purpose N

2

Analyzer Purge Schematic

N

2

Purge Inlet

N

2

Purge Vent