6 basic operation> 6-14 – Yokogawa Extractive Oxygen Gas Analyzer TDLS220 User Manual

Page 44

<6 BASIC OPERATION> 6-14

IM 11Y01B02-01E-A 4th Edition September 11, 2012-00

6.3 Non-Process Parameters (required when Instrument Air Purging)

Non-Process Parameters is the Yokogawa Laser Analysis Division term used to define regions of the op-

tical path that may be purged with a gas containing the actual target (measured) gas. The most common

application of this is to use Instrument Air (~20.9% O2) as the purge gas for analyzers measuring Oxy-

gen in the process. The Laser & Detect measurement unit will contain some oxygen molecules which

must be mathematically cancelled out using the Non-Process process parameters.

In order for the analyzer to measure correctly under these purge conditions, the analyzer must know the

correct parameters such that the measured output value has been compensated i.e. the oxygen in the

purge gas has been taken into account when determining the process oxygen concentration.

Calibration – The analyzer MUST be calibrated (Zero and Span) as per the normal methods outlined

in the standard User’s Guide. When performing a Zero Calibration, ensure that the entire optical path is

purged with Nitrogen. When performing a Span Calibration, ensure the correct procedures are followed!

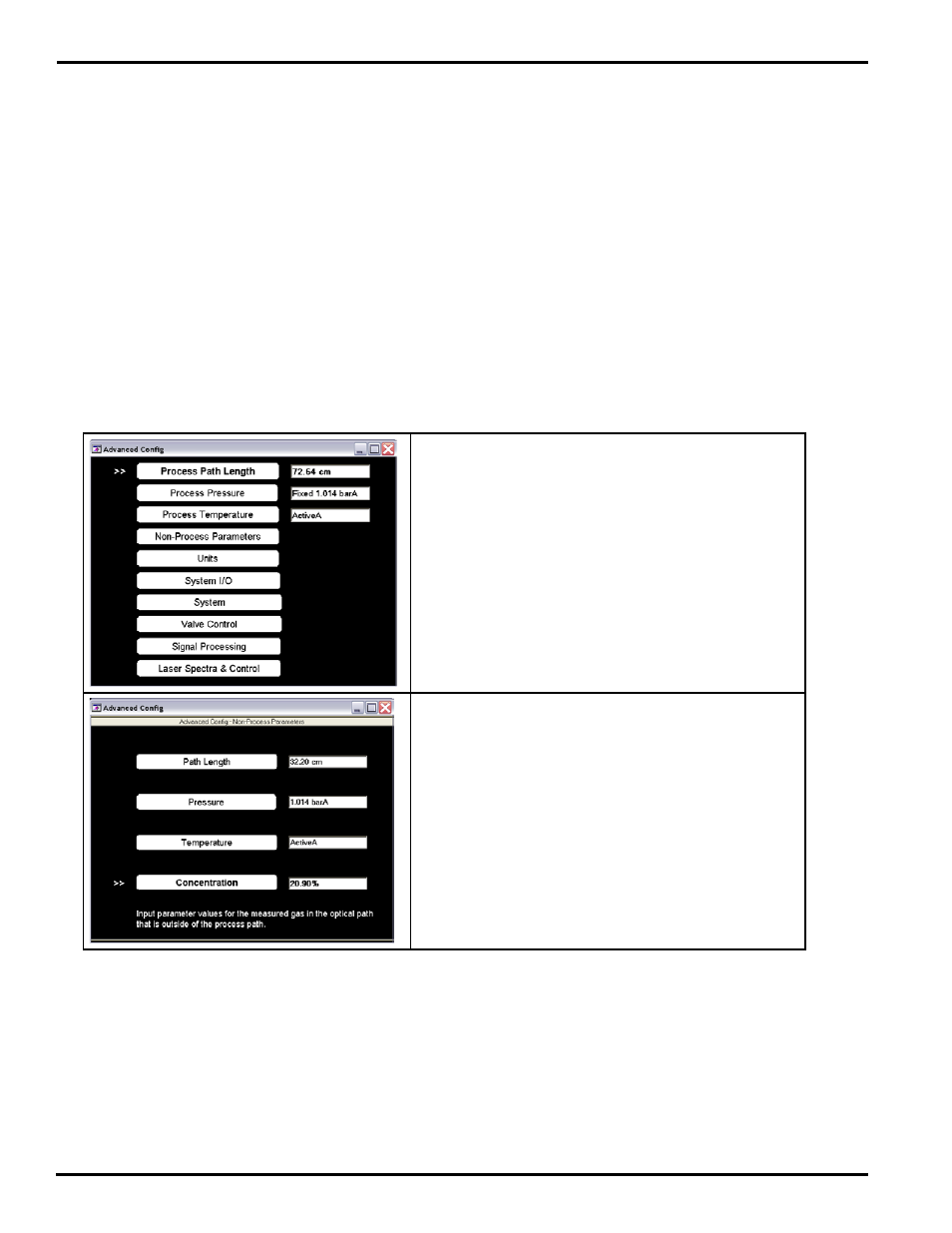

ADVANCED CONFIGURE MENU (UPDATED)

The Advanced Configure Menu has been updated with

a sub-section titled Non-Process Parameters.

NON-PROCESS PARAMETERS

These non-process parameters are for the measured

gas in the optical path but outside of the process path

length.

These parameters MUST be entered for an accurate

measurement if the purge is not nitrogen (when

measuring Oxygen).