6 basic operation> 6-7 – Yokogawa Extractive Oxygen Gas Analyzer TDLS220 User Manual

Page 37

<6 BASIC OPERATION> 6-7

IM 11Y01B02-01E-A 4th Edition September 11, 2012-00

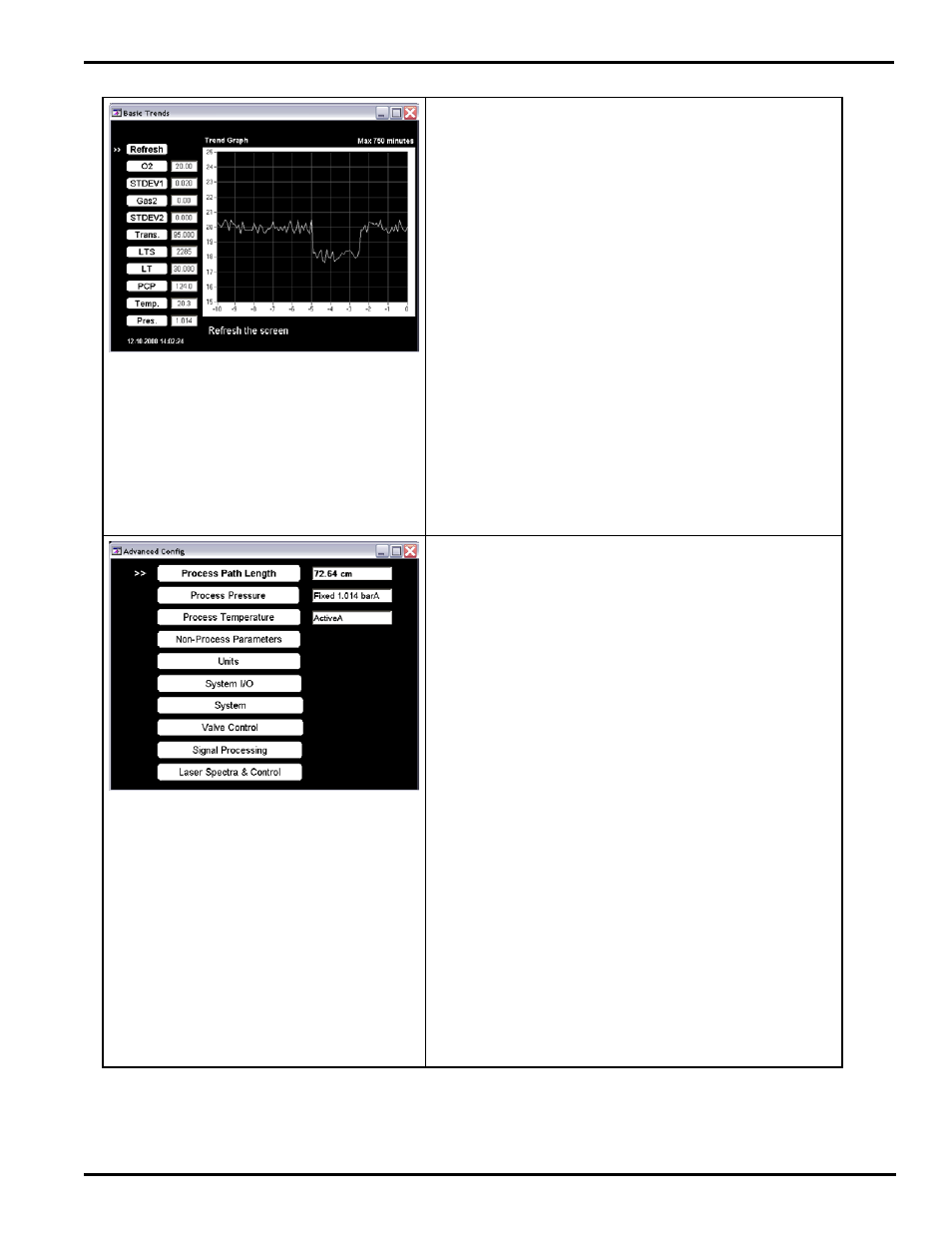

The TREND SCREEN is identical for BASIC or

ADVANCED MENUS. It allows the user to trend up to the

last 750 minutes (of current day) of data for:

REFRESH - The trend will not update automatically, use

the refresh button to update the trend

GAS 1 – analyzer reading of gas 1 concentration

STDEV1 – the standard deviation of 25 consecutive

concentration readings of Gas 1

GAS 2 – analyzer reading of gas 2 concentration

STDEV2 – the standard deviation of 25 consecutive

concentration readings of Gas 2

TRANS. – transmission % of laser light through the

process

LTS – analyzer laser temperature set point

LT – analyzer laser temperature

PCP – peak center position for the absorption peak

TEMP – process gas temperature

PRES – process gas pressure

Alongside the selection buttons the current value is

displayed. When selecting the information to trend user

will be prompted to enter minimum value, maximum value

and time to trend.

ADVANCED CONFIGURE MENU

PROCESS PATH LENGTH – DO NOT ADJUST, factory

set typical 40” (distance laser beam is exposed to

process gas).

PROCESS PRESSURE – allows selection of FIXED (value

entered into software), ACTIVE (analyzer fed pressure

value from external transducer), or CONTROL (cell

pressure controlled at a desired value with a proportional

valve and pump). In Active mode, a Back-Up value can be

entered, in case of active input failure.

TEMPERATURE – allows selection of FIXED (value

entered into software), ACTIVE INPUT (analyzer fed

temperature value from external transducer), ACTIVE

AMBIENT (ambient gas temperature derived from internal

sensor), ACTIVE PEAKS (value calculated from the

measurement spectrum), or CONTROL (cell temperature

controlled at a desired value with a heater and relay). In

Active Input mode, a Back-Up value can be entered, in

case of active input failure.

NON-PROCESS PARAMETER – if the analyzer is not

purged with a gas that is free of the component being

measured (i.e. oxygen), this allows user to enter the Path

Length, Pressure, Temperature and Concentration of

the purge gas that is present in the non-measurement

optical path (internal analyzer optical path).. For details,

see section 4.4. Use this feature if the TDLS220 is being

purged with Instrument Air (I/A)