5 optional specifications, Optional specifications -8 – Yokogawa ADMAG CA User Manual

Page 84

IM 1E8B0-01E

10-8

10. OUTLINE

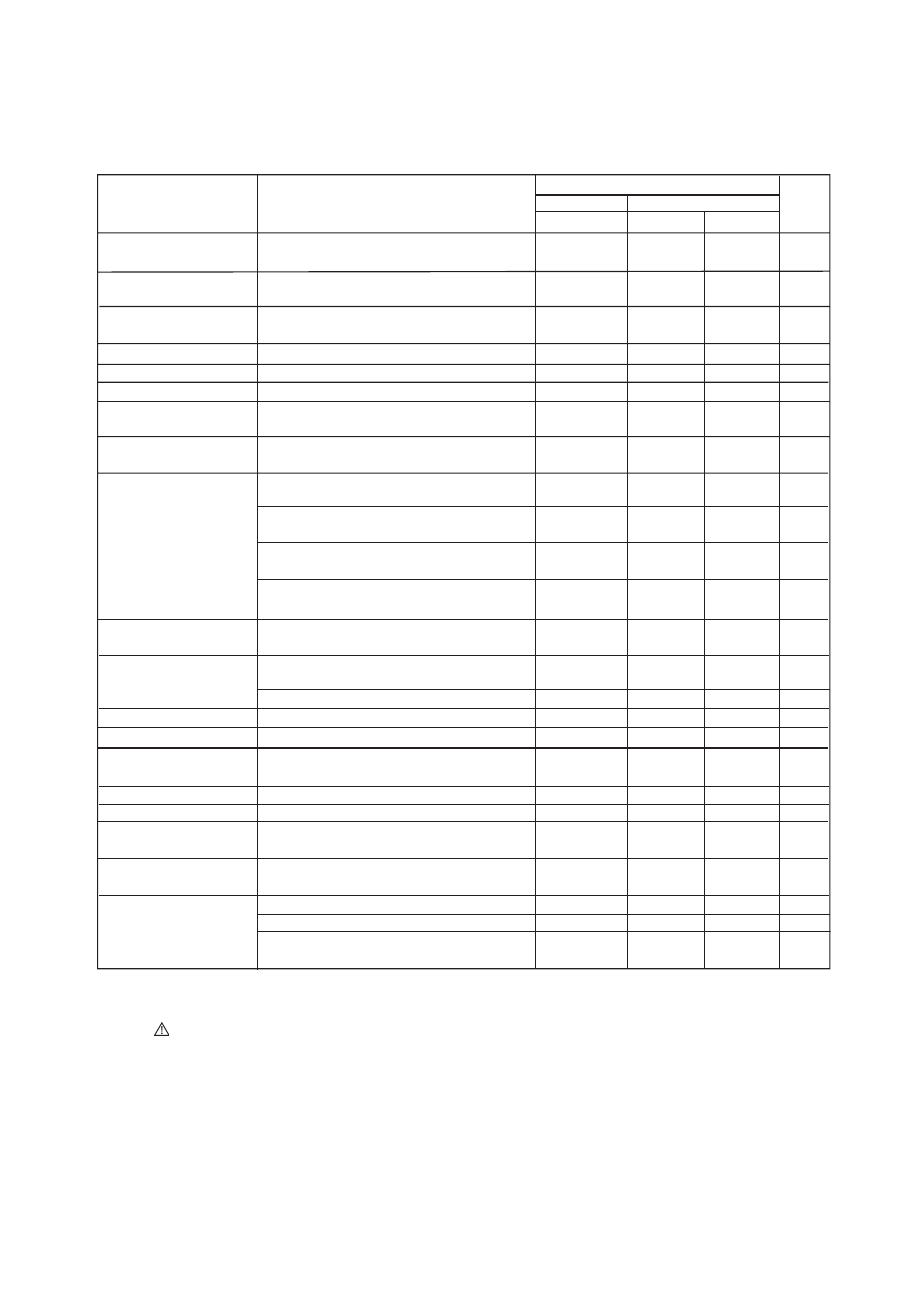

10.5 Optional Specifications

ITEM

Waterproof Gland

Waterproof Gland with

Union Joint

Gasket for PVC pipe

(Note 4)

Lightning Protector

BRAIN Communication

Epoxy Coating

High Anti-corrosion Coating

Material Certificate

Bolt & Nut Assembly

(Note 1)

TIIS(JIS) Flameproof

(Note 2) (Note 3)

Flameproof Packing Adapter

for JIS Flameproof(Note 3)

FM Approval (Note 2)

CSA Certification (Note 2)

Specification

Waterproof Glands are attached to Power and

signal wiring ports. For JIS G1/2 only.

Waterproof Glands(union joint) are attached to

Power and signal wiring ports. For JIS G1/2 only.

Gaskets are attached between earth ring

and flow tube.

Built-in Lightning Protector(Only for 24VDC version)

Digital communication with BRAIN protocol

Coating is changed to Epoxy coating.

Coating is changed to three-layer coating

(Urethane coating on two-layer epoxy coating)

Reproduced material certificate for earth ring.

Carbon steel bolts/nuts and chloroprene gaskets

assembly.

Carbon steel bolts/nuts and non-asbestos PTFE-

wrapped gaskets assembly.

Stainless steel bolts(SUS304)/nuts(SUS403)

and chloroprene gaskets assembly.

Stainless steel bolts(SUS304)/nuts(SUS403)

and non-asbestos PTFE-wrapped gaskets assembly.

TIIS(JIS) Flameproof type

One Flameproof Packing Adapter and a blind plug are

attached.

Two Flameproof Packing Adapters are attached.

FM Explosion proof/FM Non-incendive type

CSA Explosion proof/CSA Non-incendive type

Use

General Purpose Ex.Proof

CA***SG

CA***SC CA***SN

Code

A : Available N : Not available

A

A

A

A

A

A

A

A

A

A

A

A

N

N

N

N

N

A

A

A

A

A

A

A

A

Mirror Finished Ceramics

180deg. Rotate Converter

Oil-prohibited Use

Oil-prohibited Use with

Dehydrating Treatment

Hydrostatics Test Certificate

Calibration Certificate

Mirror Finishing on the inside of ceramic tube

(Rmax. <= 1micro-meter)

180deg. rotate converter for reversed flow direction

Degreased cleansing treatment

Degreased cleansing treatment; Packing with

desiccant

Test pressure depends on process connection (Test

duration 10minutes) Test result is full in NOTE of QIC.

Level2: Declaration and Calibration Equipment List

Level3: Declaration and Primary Standard List

Level4: Declaration and YOKOGAWA Measuring

Instruments Control System

N

N

A

A

A

A

A

A

A

A

A

A

Note3

Note3

Note3

N

N

A

A

A

A

A

A

A

A

N

N

A

A

A

A

A

A

A

A

A

A

N

N

N

A

A

A

A

A

A

A

A

A

A

/ECG

/ECU

/FRG

/A

/BR

/EPF

/X2

/M01

/BCC

/BCF

/BSC

/BSF

/JF3

/G11

/G12

/FF1

/CF1

/MRR

/CRC

/K1

/K5

/T01

/L2

/L3

/L4

Note 1: It is available only for JIS 10K wafer, JIS 20K wafer or ANSI 150 wafer type.

2: It is available only for size 15 to 100mm (0.5 to 4 in).

3: Select optional code /JF3 with /G11 or /G12 in case of requirement of JIS Flameproof type.

/G11 is selectable only for DC power supply and 4-conductor cable use.

4:

Users must consider the characteristics of selected wetted parts material and the influence of process fluids. The use of

inappropriate materials can result in the leakage of corrosive process fluids and cause injury to personnel and/or damage to plant

facilities. It is also possible that the instrument itself can be damaged and that fragments from the instrument can contaminate the

user's process fluids.

Be very careful with highly corrosive process fluids such as hydrochloric acid, sulfuric acid, hydrogen sulfide, sodium hypochlorite,

and high-temperature steam (150

°

C [302

°

F] or above).

Contact Yokogawa for detailed information of the wetted parts material.