Yokogawa ADMAG CA User Manual

Page 75

IM 1E8B0-01E

9-5

9. MAINTENANCE

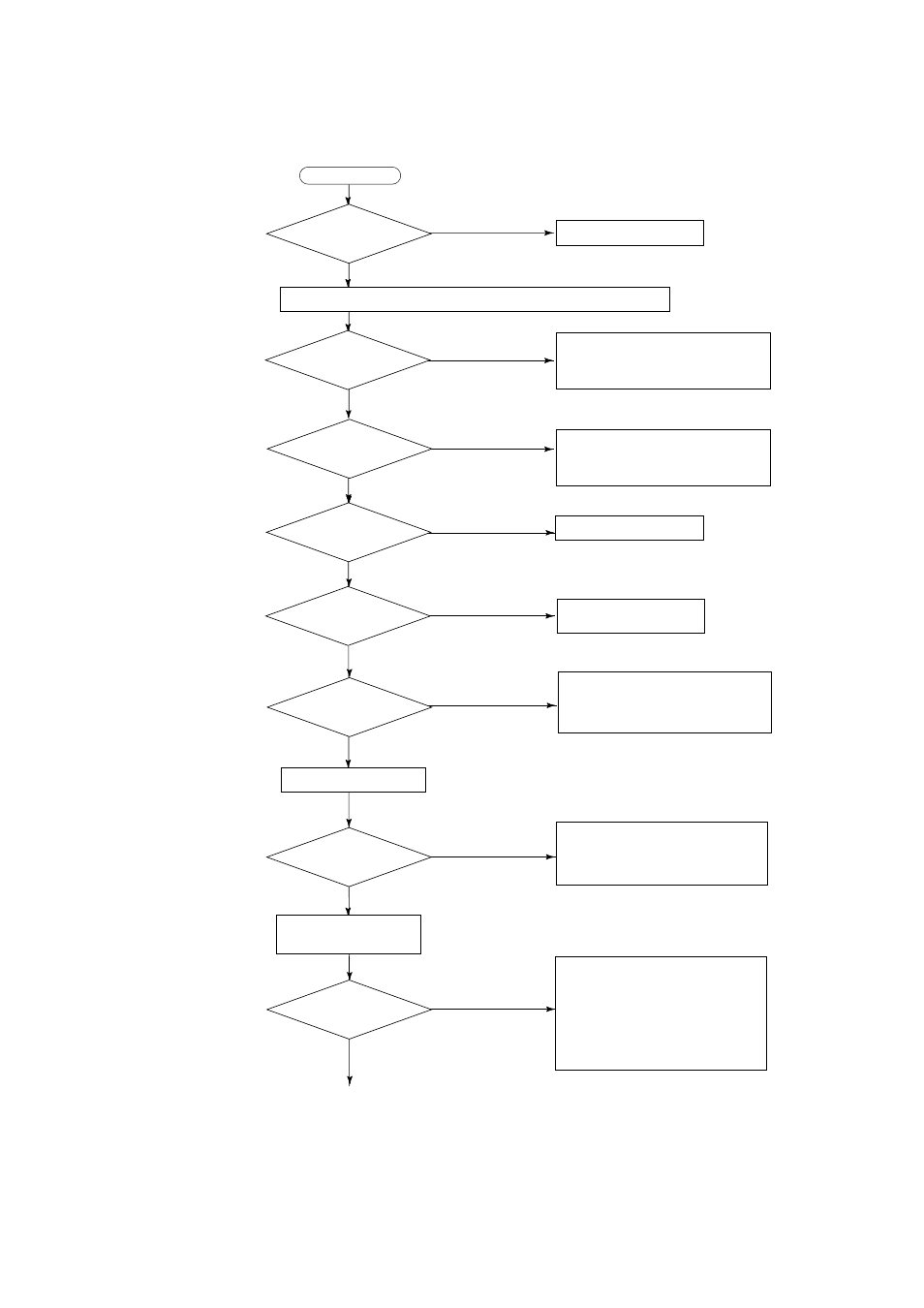

9.3.3 Disagreement of Indication with Actual Flow Result

NO

NO

NO

YES

NO

NO

CONTINUE

YES

YES

YES

NO

YES

YES

NO

YES

Set the parameters correctly.

Examine liquid filling in the meter tube, bubbles present, and grounding status.

Adjust zero when the meter tube is

compleltely filled with liquid and is

standing still.

Recheck the liquid property.

• Change the meter mounting position or

piping so that the meter tube is completely

filled with liquid.

• Mount the meter vertically with upward flow.

Provide a defoaming device on

the upstream side of the meter.

Grounding resistance must be

100

Ω

or less.

Completely perform end-treatment of the signal

cable with PVC tubes or insulation tape so that

the conductors, inner shields, and outer shield

do not contact each other or with the case.

a. Remove scales. Especially clean the

electrodes and their vincinity.

b. Remove scales with a soft brush or a piece

of soft cloth. Never claw or scratch the

lining.

NO

YES

a. If a valve located immidiately upstream of

the meter is used half opened, the

indication may be affected with flow

turbulency.

b. Move the valve downstream of the meter.

c. If the valve must be located on the

upstream side, allow for a minimum

distance to the meter of 10 times the meter

diameter or use the valve fully open.

Examine whether or not a valve

exists immidiately before rhe

meter (on the upstream side).

START

Are parameters correctly set?

Is zero adjustment

correctly done?

Is the meter tube completely

filled with liquid?

Does the liquid contain bubbles?

Is grounding complete?

Is the signal cable completely

end-treated?

Is the liquid likely to cause

deposits?

Is a valve located

immidiately upstream of

the meter?