2 unstable zero, Unstable zero -4 – Yokogawa ADMAG CA User Manual

Page 74

IM 1E8B0-01E

9-4

9. MAINTENANCE

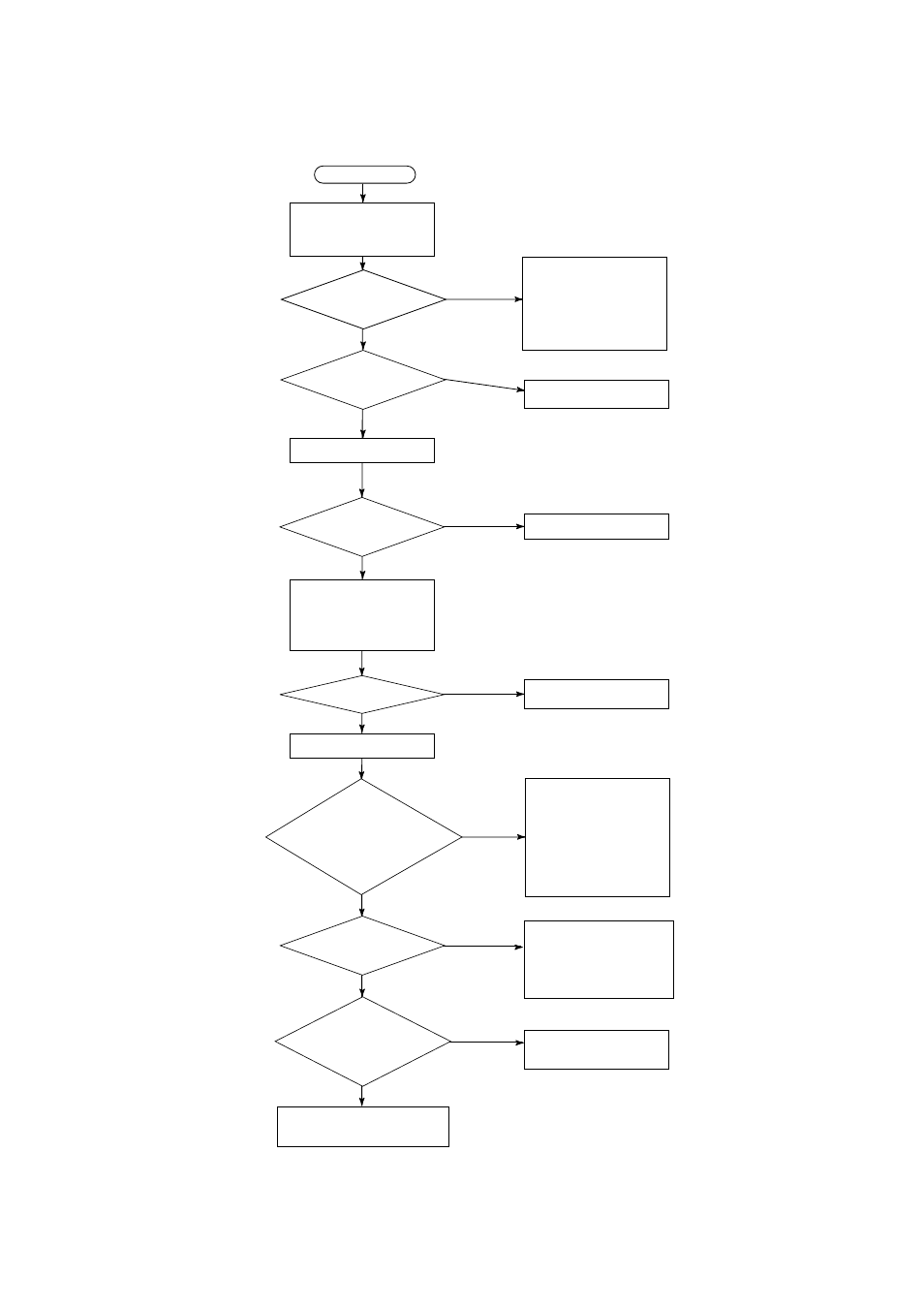

9.3.2 Unstable Zero

NO

Examine whether or not the

meter tube is filled with liquid

and the liquid does not contain

bubbles.

Examine whether or not the

valves leak.

Recheck liquid property.

Replace valves.

Sufficiency shield the meter.

Locate the meter as far as

possible from this equipment.

NO

NO

NO

YES

NO

NO

NO

YES

YES

YES

YES

YES

YES

It is convenient to provide a gas

vent hole on the downstream

side of the meter to check for

bubbles.

In particular, be careful for

horizontal meter mouting,.

Change mounting position or

change to vertical mounting

with upward flow so that the

tube is completely filled with

liquid.

Mount a deforming device on

the upstream side of the meter

· Confirm the meter grounding.

· Confirm whether or not the

grounding wire is

disconnected from the earth

flange.

a, Insure that the liquid

conductivity does not change

beyond fluid limits.

b, Do not use the meter with

liquid conductivity below the

specified value.

c, Decrease flow velocity near

the conductivity low limit as

much as passble.

• Remove dirt and scale on

and near electrodes.

• Change to vertical meter

mounting.

• Change the measuring mode

to the standard mode.

START

Are bubbles contained in the

liquid?

Is the meter tube filled with

liquid completely?

Are valves leaking?

• Does the fluid

conductivity vary or is

it easy to change?

• Is Liquid conductivity

sometimes below the

specified value?

Is the liquid likely to cause

deposit?

Is the flowmeter located

near mortors, transformers, or

other electric equipment?

*

*

Is grounding complete?

Insulation deterioration is suspected.

Examine the meter.

Grounding resistance must be

100

Ω

or less.