Installation, 1 piping design precautions, Installation -1 – Yokogawa ADMAG CA User Manual

Page 10: Piping design precautions -1, Warning important important important important

4.INSTALLATION

IM 1E8B0-01E

4-1

4. INSTALLATION

This instrument must be installed by expert engineer or skilled personnel.

The procedures described in this chapter are not permitted for operators.

4.1 Piping Design Precautions

Please design the correct piping referring to the followings to prevent

damage for flowmeter and to keep correct measuring.

(1) Location

Please install the flowmeter to the location where it is not exposed to direct

sunlight and ambient temperature is -20 to +50˚C (-4 to 122˚F) .

(2) Noise Rejection

• The instrument should be installed away from large electrical motors,

transformers and other power sources in order to avoid interference with

the measurement.

• In case several capacitance Magnetic Flowmeters are installed, please

install them 1 m (40 in) or more apart.

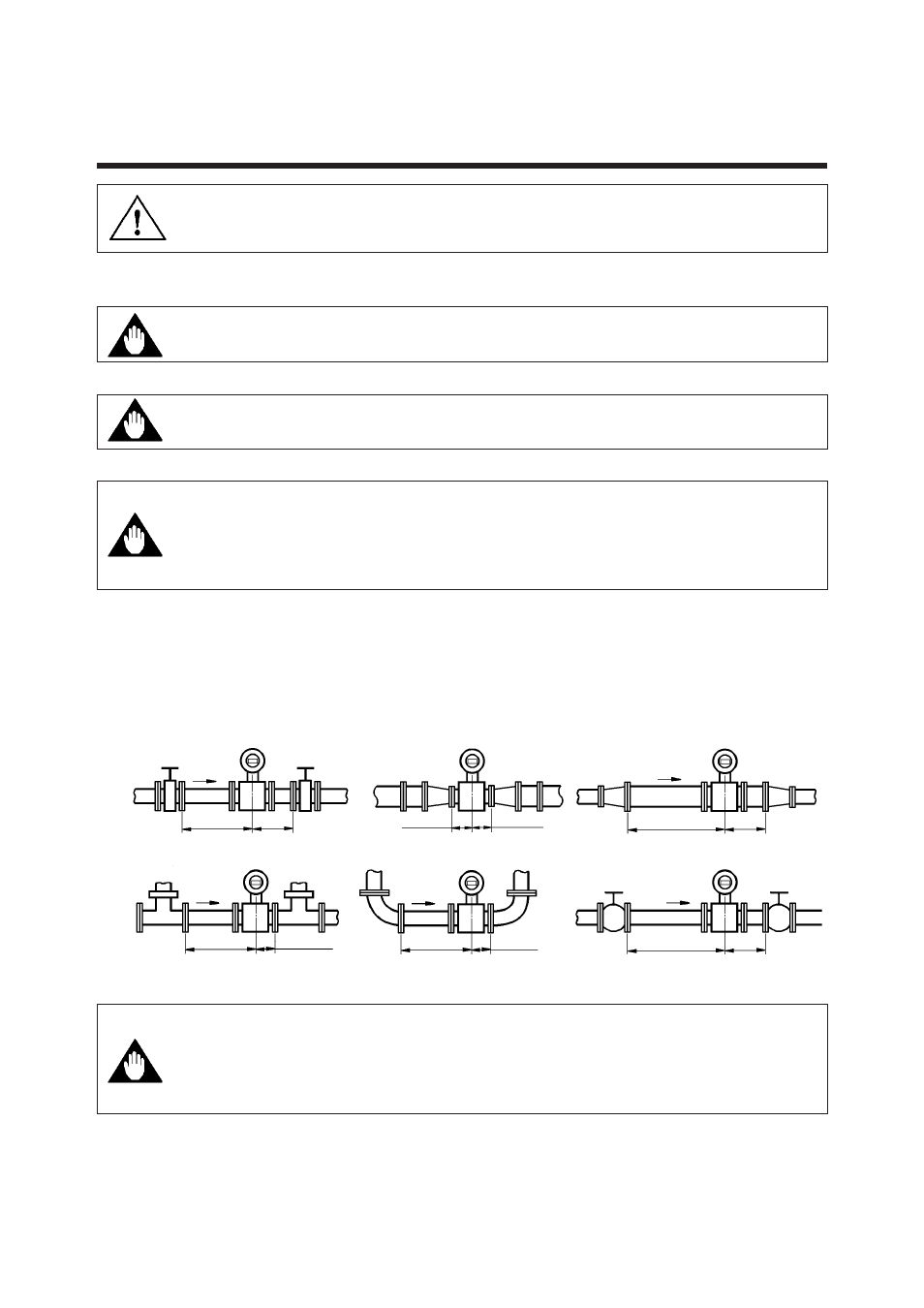

(3) Length of Straight Run

To keep accurate measuring, JIS B7554 “Electro Magnetic Flowmeters” explains about

upstream piping condition of Magnetic Flowmeters.

We recommend to our customers about the piping conditions shown in Figure 4.1.1

based on JIS B7554 and our piping condition test data.

D:Internal diameter of flowmeter

Gate valve fully open

Reducer pipe

90 degrees bent

Various type of valves

5D or more

5D or more

2D or more

Expander pipe

10D or more

2D or more

10D or more

2D or more

Do not care to 0D

Do not care to 0D

5D or more

Do not care to 0D

Tee

Figure 4.1.1

Minimum Length of Required Straight Run

In the application for pure water, pure alcohol and other fluids which have

low conductivity with low viscosity, we recommend the upper stream length

of straight run of magmeter be 20D ( where D denotes size of flow tube) or

more. Please be careful that gasket material dose not protrude in pipe

inner surface.

Notes : 1. Nothing must be inserted or installed in the metering pipe that may interfere with the magnetic

field, induced signal voltages, and flow velocity distribution.

2. These straight runs may not be required on the downstream side of the flowmeter. However, if

the downstream valve or other fittings cause channeling on the upstream side, provide a straight

run of 2 D to 3 D on the downstream side.

WARNING

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT