Yokogawa ADMAG CA User Manual

Page 21

4.INSTALLATION

I

M 1E8B0-01E

4-12

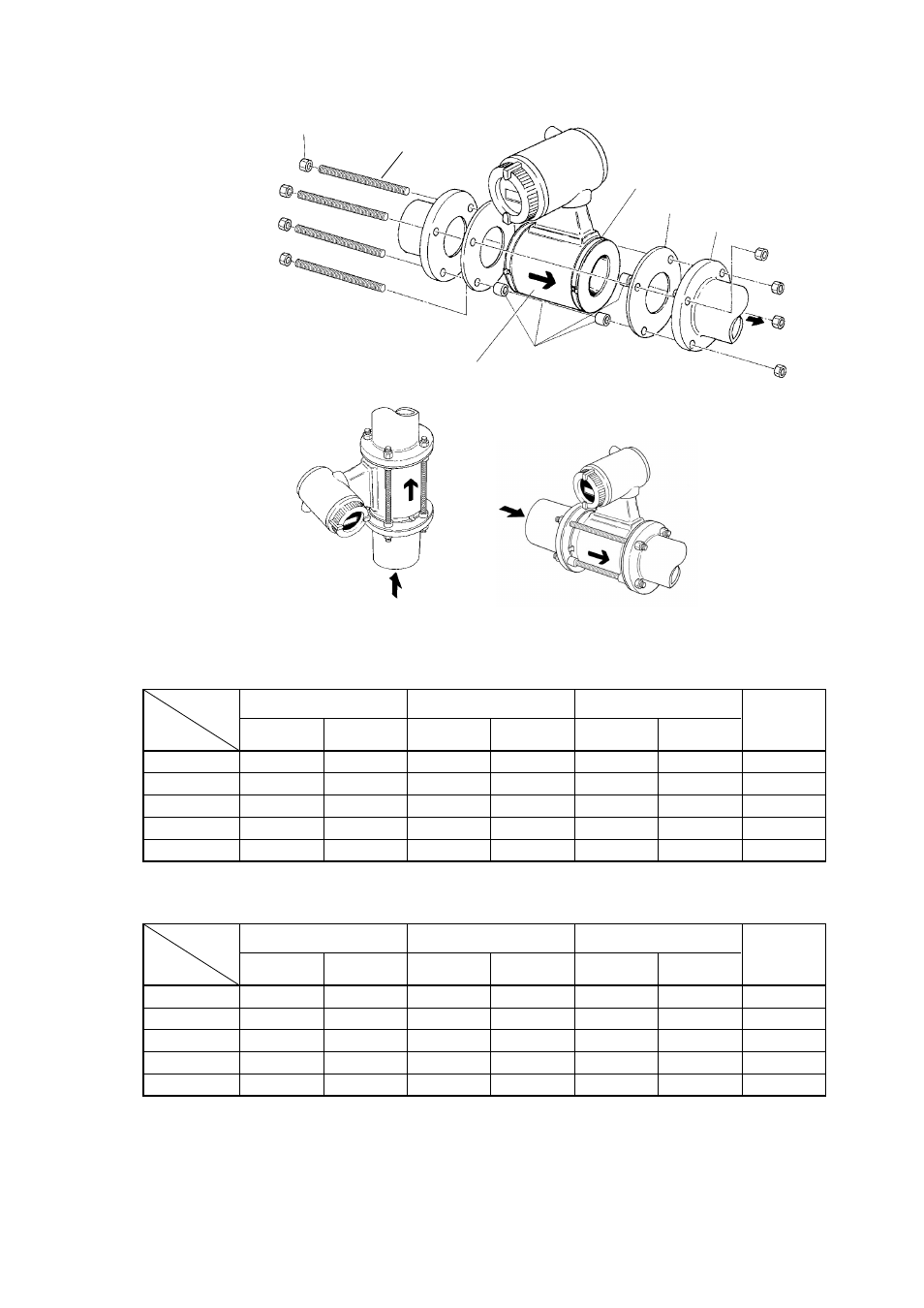

Nuts

Through bolts

Mini-Flange

Gaskets

Flange

Housing

Centering devices (four)

Please use appropriate

bolts and nuts according to

process connection.

Vertical Mounting

Horizontal Mounting

Figure 4.3.3 Mounting Procedure

Table 4.3.3

Maximum Torque Value for Metal Piping N·m {kgf·cm} [in-lbf]

Flange

Rating

Size

mm(inch)

JIS

10K

20K

150

300

PN 10

PN 16

ANSI

DIN

JIS G3451

F12(75M)

50(2)

80(3)

100(4)

150(6)

200(8)

50{510}[442]

36{367}[319]

48{490}[425]

79{806}[699]

70{714}[619]

27{276}[239]

44{449}[389]

58{592}[513]

55{561}[487]

76{776}[673]

50{510}[442]

75{765}[664]

49{500}[434]

66{673}[584]

102{1041}[903]

27{276}[239]

44{449}[389]

56{571}[496]

43{439}[381]

76{776}[673]

—

—

—

—

103{1051}[911]

63{643}[558]

36{367}[319]

48{490}[425]

76{776}[673]

67{684}[593]

—

80{816}[708]

105{1071}[929]

84{857}[743]

102{1041}[903]

* Please use compressed non-asbestos fiber gasket, PTFE gasket or the gasket which has equal elasticity.

Table 4.3.4

Maximum Torque Value for PVC Piping N·m {kgf·cm} [in-lbf]

Flange

Rating

Size

mm(inch)

JIS

10K

20K

150

300

PN 10

PN 16

ANSI

DIN

JIS G3451

F12(75M)

50(2)

80(3)

100(4)

150(6)

200(8)

8.2{84}[73]

6.2{63}[55]

8.0{82}[71]

19.8{202}[175]

17.5{179}[155]

—

—

—

—

—

8.2{84}[73]

12.4{127}[110]

8.1{83}[72]

18.9{193}[167]

25.1{256}[222]

—

—

—

—

—

—

—

—

19.8{202}[175]

26.2{267}[232]

8.2{84}[73]

6.2{63}[55]

8.0{82}[71]

19.8{202}[175]

17.5{179}[155]

—

12.3{126}[109]

16.1{164}[142]

21.6{220}[191]

28.7{293}[254]

* Please select optional code /FRG and use rubber gasket or others which has equal elasticity.