Filter time constant, Sensor selection, Scale high and scale low – Watlow EZ-ZONE RM-Scanner-Modul User Manual

Page 90

Watlow EZ-ZONE

®

RMS Module

•

87

•

Chapter 6 Features

2. Record the Calibration Offset [`i;CA] parameter

value in the Operations Page [oPEr] , Analog In-

put Menu [``Ai] then set value to zero.

3. Wire the precision source to the appropriate con-

troller input terminals to be calibrated. Do not

have any other wires connected to the input ter-

minals. Please refer to the Install and Wiring sec-

tion of this manual for the appropriate connec-

tions.

4. Ensure the controller sensor type is programmed

to the appropriate Sensor Type [`SEn] to be uti-

lized in the Setup Page [`SEt] , Analog Input

Menu

[``Ai]

.

5. Enter Factory Page [FCty] , Calibration Menu

[`CAL] via RUI or EZ-ZONE Configurator Soft-

ware.

6. Select the Calibration [CAL] input instance to be

calibrated. This corresponds to the analog input to

be calibrated.

7. Set Electrical Input Slope [ELi;S] to 1.000 and

Electrical Input Offset [ELi;o] to 0.000 (this will

cancel any prior user calibration values)

8. Input a Precision Source Low value. Read Elec-

trical Measurement value [`Mu] of controller via

EZ-Configurator or RUI. This will be referred to

as Electrical Measured Low.

Record low value ______________

9. Input a Precision Source High value.

10. Read Electrical Measurement value [`Mu] of

controller via EZ-Configurator or RUI. This will

be referred to as Electrical Measured High.

Record high value ______________

11. Calculated Electrical Input Slope = (Precision

High – Precision Low) / (Electrical Measured High

– Electrical Measured Low)

Calculated Slope value ___________

12. Calculated Electrical Input Offset = Precision

Low – (Electrical Input Slope * Measured Low)

Calculated Offset value ___________

13. Enter the calculated Electrical Input Slope

[ELi;S] and Electrical Input Offset [ELi;o] into

the controller.

14. Exit calibration menu.

15. Validate calibration process by utilizing a calibra-

tor to the analog input.

16. Enter calibration offset as recorded in step 2 if re-

quired to compensate for sensor error.

Setting Electrical Input Slope [ELi;S] to 1.000 and

Electrical Input Offset [ELi;o] to 0.000, restores fac-

tory calibration as shipped from factory.

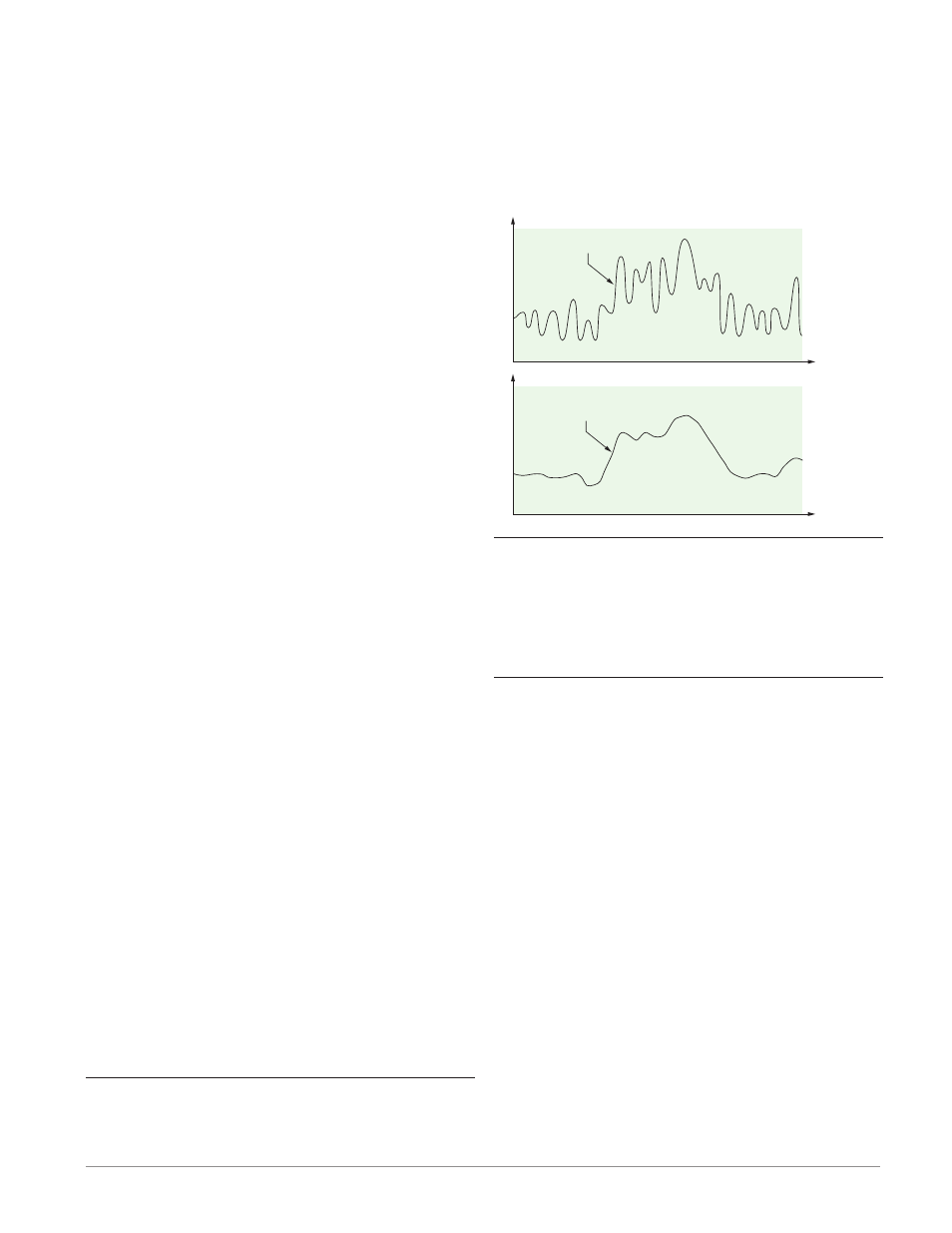

Filter Time Constant

Filtering smoothes an input signal by applying a

first-order filter time constant to the signal. Filter-

ing the displayed value makes it easier to monitor.

Filtering the signal may improve the performance of

PID control in a noisy or very dynamic system.

Adjust the filter time interval with Filter Time

[`FiL]

(Setup Page, Analog Input Menu). Example:

With a filter value of 0.5 seconds, if the process input

value instantly changes from 0 to 100 and remained at

100, the display will indicate 100 after five time con-

stants of the filter value or 2.5 seconds.

Filter Time Constant

Unfiltered Input Signal

Time

Temperature

Filtered Input Signal

Time

Temperature

Sensor Selection

You need to configure the controller to match the in-

put device, which is normally a thermocouple, RTD or

process transmitter.

Select the sensor type with Sensor Type [`Sen]

(Setup Page, Analog Input Menu).

Scale High and Scale Low

When an analog input is selected as process voltage

or process current input, you must choose the value

of voltage or current to be the low and high ends. For

example, when using a 4 to 20 mA input, the scale

low value would be 4.00 mA and the scale high value

would be 20.00 mA. Commonly used scale ranges are:

0 to 20 mA, 4 to 20 mA, 0 to 5V, 1 to 5V and 0 to 10V.

You can create a scale range representing other

units for special applications. You can reverse scales

from high values to low values for analog input sig-

nals that have a reversed action. For example, if 50

psi causes a 4 mA signal and 10 psi causes a 20 mA

signal.

Scale low and high low values do not have to match

the bounds of the measurement range. These along

with range low and high provide for process scaling

and can include values not measureable by the con-

troller. Regardless of scaling values, the measured val-

ue will be constrained by the electrical measurements

of the hardware.

Select the low and high values with Scale Low

[`S;Lo]

and Scale High [`S;hi]. Select the displayed

range with Range Low [`r;Lo] and Range High