Saving and restoring user settings, Inputs, Saving and restoring user settings inputs – Watlow EZ-ZONE RM-Scanner-Modul User Manual

Page 89: Calibration offset, Calibration

Watlow EZ-ZONE

®

RMS Module

•

86

•

Chapter 6 Features

Saving and Restoring User Settings

Recording setup and operations parameter settings

for future reference is very important. If you uninten-

tionally change these, you will need to program the

correct settings back into the controller to return the

equipment to operational condition.

After you program the controller and verify prop-

er operation, use User Save Set [USr;S] (Setup Page,

Global Menu) to save the settings into either of two

files in a special section of memory. If the settings

in the controller are altered and you want to return

the controller to the saved values, use User Restore

Set [USr;r] (Setup Page, Global Menu) to recall one

of the saved settings. A digital input or the Function

Key can also be configured to restore parameters.

Note:

Starting with firmware release 6, there is only one

user set.

Note:

Only perform the above procedure when you are

sure that all the correct settings are programmed

into the controller. Saving the settings overwrites

any previously saved collection of settings.

Be sure to document all the controller settings.

Note:

When restoring factory defaults, I/O assemblies for

Modbus, DeviceNet, Profibus and Ethernet along

with the zone address will be overwritten when re-

storing factory defaults.

Inputs

Calibration Offset

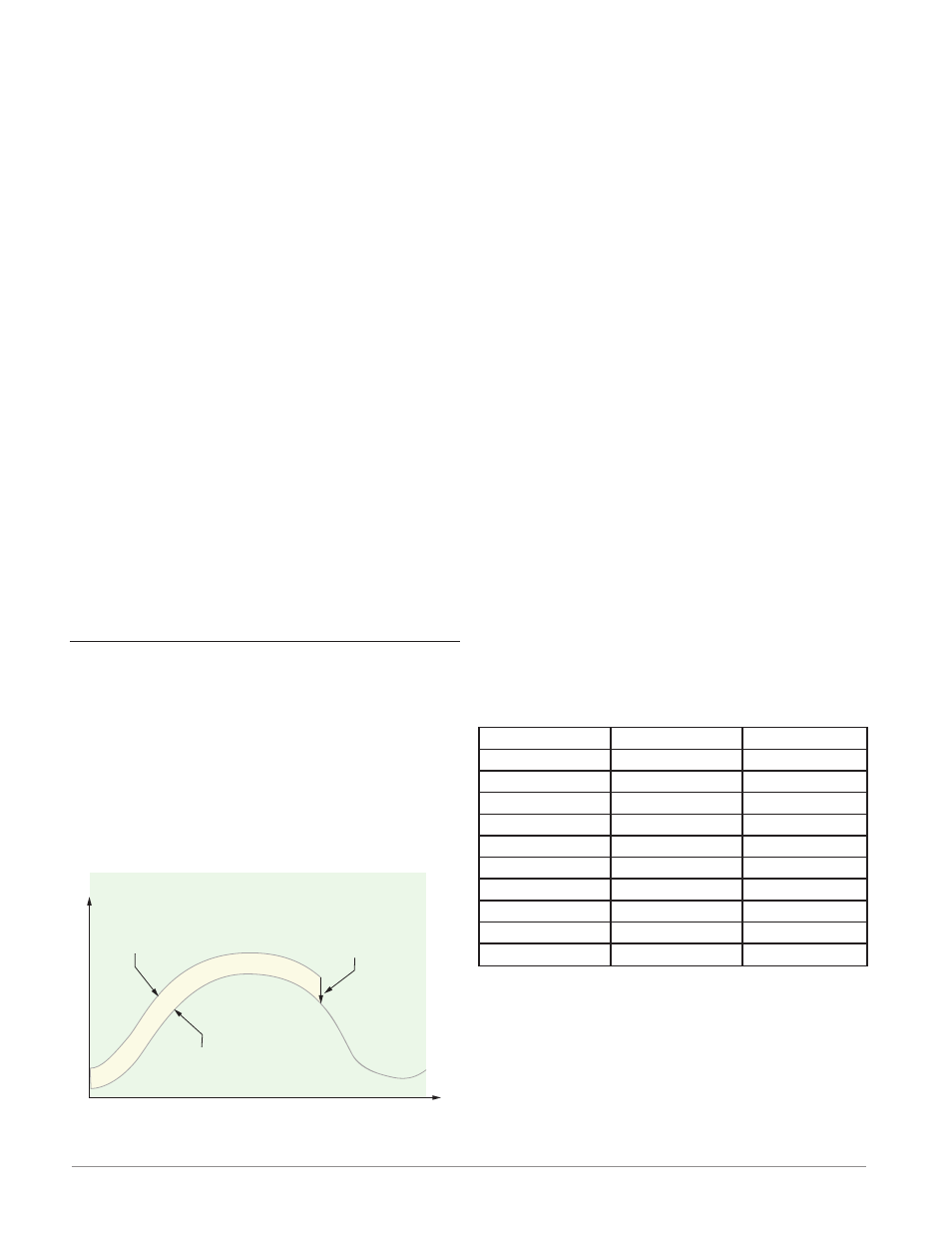

Calibration offset allows a device to compensate for

an inaccurate sensor, lead resistance or other factors

that affect the input value. A positive offset increases

the input value, and a negative offset decreases the

input value.

The input offset value can be viewed or changed

with Calibration Offset [`i;CA] (Operations Page,

Analog Input Menu).

Time

Temperature

Temperature Reading

from Sensor

Actual Process Temperature

Negative Calibration Offset will

compensate for the difference

between the Sensor Reading and

the Actual Temperature

Calibration

Before performing any calibration procedure, verify

that the displayed readings are not within published

specifications by inputting a known value from a pre-

cision source to the analog input. Next, subtract the

displayed value with the known value and compare

this difference to the published accuracy range speci-

fication for that type of input.

Use of the Calibration Offset [`i;CA] parameter

found in the Operations Page [oPEr] , Analog Input

Menu [``Ai] shifts the readings across the entire

displayed range by the offset value. Use this param-

eter to compensate for sensor error or sensor place-

ment error. Typically this value is set to zero.

Equipment required while performing calibra-

tion: Obtain a precision source for millivolts, volts,

milliamperes or resistance depending on the sensor

type to be calibrated. Use copper wire only to connect

the precision source to the controller’s input. Keep

leads between the precision source and controller as

short as possible to minimize error. In addition, a

precision volt/ohm meter capable of reading values to

4 decimal places or better is recommended. Prior to

calibration, connect this volt/ohm meter to the preci-

sion source to verify accuracy.

Actual input values do NOT have to be exactly the

recommended values, but it IS critical that the actual

value of the signal connected to the controller be ac-

curately known to at least four digits.

Calibration of Analog Inputs:

To calibrate an analog input, you will need to provide

a source of two electrical signals or resistance values

near the extremes of the range that the application is

likely to utilize. See recommended values below:

Sensor Type

Low Source

High Source

thermocouple

0.000 mV

50.000 mV

millivolts

0.000 mV

50.000 mV

volts

0.000V

10.000V

milliamps

0.000 mA

20.000 mA

100 Ω RTD

50.00 Ω

350.00 Ω

1,000 Ω RTD

500.00 Ω

3,500.00 Ω

Thermistor 5K

50.00 Ω

5000.00 Ω

Thermistor 10K

50.00 Ω

10000.00 Ω

Thermistor 20K

50.00 Ω

20000.00 Ω

Thermistor 40K

50.00 Ω

40000.00 Ω

Note:

The user may only calibrate one sensor type. If the

calibrator interferences with open thermocouple

detection, set Sensor Type [`SEn] in Setup Page

[`SEt]

, Analog Input Menu [``Ai] to millivolt

[`Mu]

instead of Thermocouple [``tC] to avoid

interference between the calibrator and open ther-

mocouple detect circuit for the duration of the cali-

bration process. Be sure to set sensor type back to

the thermocouple type utilized.

1. Disconnect the sensor from the controller.