Ransburg, Troubleshooting guide - direct charge, Cont.) – Ransburg MMA-570 Direct_Ind Charge Atomizer A13366 User Manual

Page 82: Mma-570 direct/indirect charge - maintenance

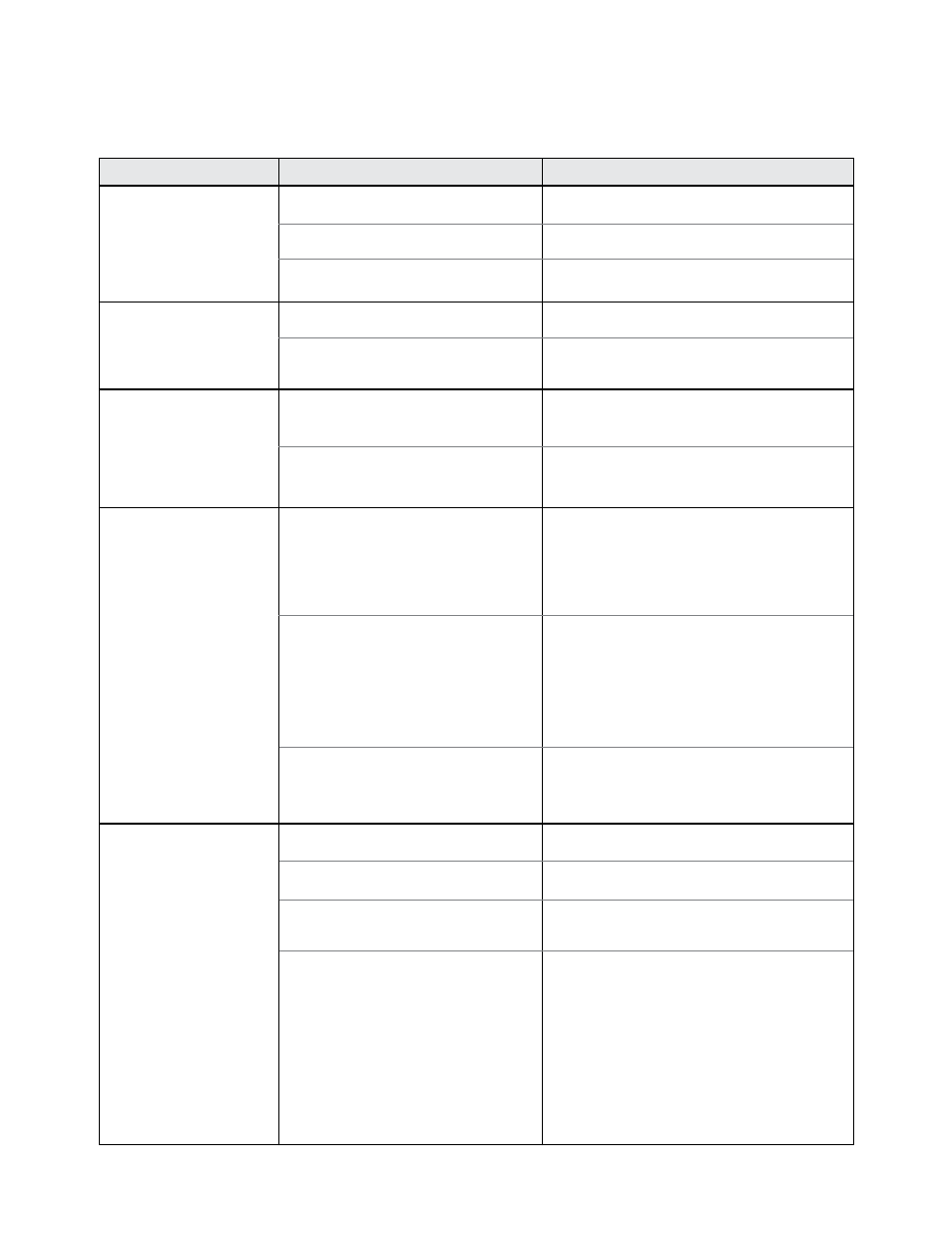

TROUBLESHOOTING GUIDE - DIRECT CHARGE

(Cont.)

Atomizer mounting ring is loose

O-ring is missing

O-ring is damaged

O-ring is damaged

Fluid tubing not properly installed

or tightened.

Damaged o-ring(s) on outer

diameter of valve body

Damaged or worn needle

seals inside valve assembly

Excessive vibration

Low or no bearing air

Loss of fiber optic/no feed

back

Bent of kinked supply tube

No fluid flow

Blocked fluid tip or external

nozzle.

Ferrules holding tubing over

-tightened.

Tighten mounting ring.

Install O-ring.

Visually inspect for damage and replace.

Replace O-ring.

Inspect and retighten.

Replace o-ring(s).

Replace valve assembly.

a. Check bell cup for damage

b. Check bell cup for excessive paint buildup

c. Bell cup loose - tighten to proper torque

d. Check cup and shaft tapers for cleanliness

e. Have manufacturing check bell cup balance

a. Check bearing air pressure (minimum 80

psi) (352 kPa)

b. Check filters for contamination

c. Check for bent or damaged bearing air line

d. Poor turbine air pressure - plant air

e. Damaged speed control cards

Damaged fiber optic sensor, bad cable, too

many splices. Maximum three (3) slices

per-mitted.

Replace.

Check microvalve, check fluid supply source.

Clean parts, remove obstruction.

Replace tubing and ferrule assembly.

General Problem

Possible Cause

Solution

Fluid and/or Air

Leakage Between

the Robot and Bell

Manifold Plates

Fluid Leakage In

Fluid Manifold or

Bell Plate

Fluid Leakage

Around Fluid Valve

Turbine Cannot

Attain Desired

Speed

Loss of Exterior/

Interior Cup Wash

or Lack of Flow

MMA-570 Direct/Indirect Charge - Maintenance

Ransburg

LN-9279-13

79