Troubleshooting guide - direct charge, Ransburg, Mma-570 direct/indirect charge - maintenance – Ransburg MMA-570 Direct_Ind Charge Atomizer A13366 User Manual

Page 79

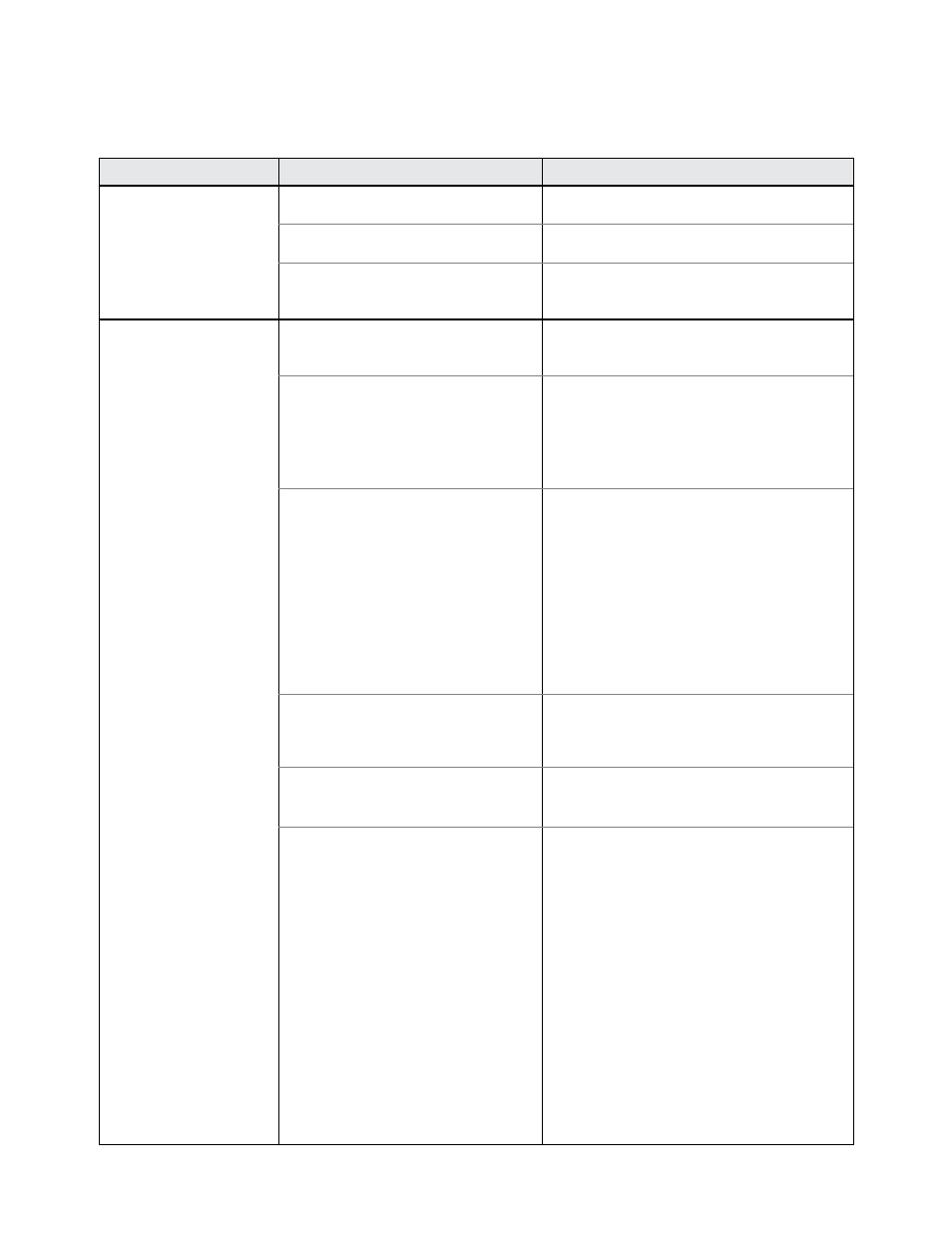

TROUBLESHOOTING GUIDE - DIRECT CHARGE

Bell cup damaged

Low voltage

Paint lodged in shaping air ring

High current draw

Solvent valve is actuated

Loss of low voltage cable

connection between robot and

bell plates

Improperly mounted air

turbine

Improper limiting current and

voltage settings high voltage parts

Atomizer grounding out (usually

indicated by high current draw or by

MicroPak over-current fault light)

Replace bell cup.

See “Low or No High Voltage” below.

Disassemble and clean

(see “Maintenance” section).

a. Paint resistivity to be .1 MW to h.

b. Replace coiled fluid line.

Remove solvent valve air pilot signal

(high voltage must be interlocked with

the solvent valve air pilot signal to pre-

vent solvent flow while high voltage is

energized).

a. Remove atomizer and inspect low volt-

age connections on both plates. Verify

bell plates alignment marks between

connectors and plates and verify that

connector face is flush with plate.

Verify that set screws are secure, but

not too tight, as this will prevent the

spring-loaded pins on the robot plate

from extending and making contact.

b. Faulty low voltage cable.

Verify correct orientation of air turbine so

that high voltage spring makes contact

with metal pad on turbine assembly.

To readjust settings, refer to “MicroPak”

operating manual.

a. Clean atomizer externally with non-po-

lar solvent.

b. Check the atomizer externally with

non-polar solvent.

c. Check for fluid leaks at quick discon-

nect mounting (between bell plate and

robot plate).

d. Check for internal arcing (usually indi-

cated by internal sparking sounds).

e. Make sure cascade low voltage con-

nection is properly shielded.

General Problem

Possible Cause

Solution

Bad Spray Pattern

Low or No High

Voltage

MMA-570 Direct/Indirect Charge - Maintenance

Ransburg

LN-9279-13

76