Ransburg, Troubleshooting guide - direct charge, Cont.) – Ransburg MMA-570 Direct_Ind Charge Atomizer A13366 User Manual

Page 81: Mma-570 direct/indirect charge - maintenance

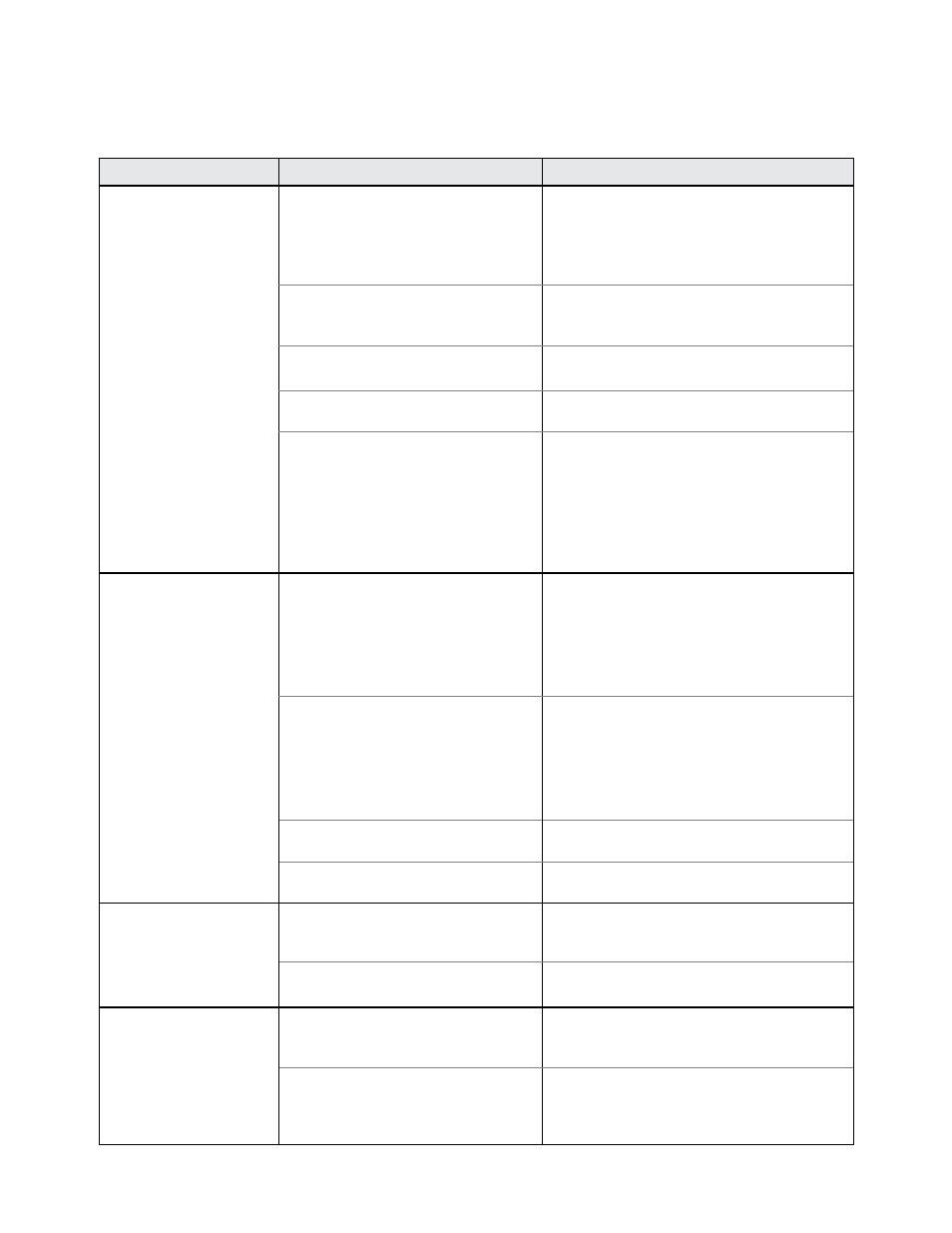

TROUBLESHOOTING GUIDE - DIRECT CHARGE

(Cont.)

Damaged fiber optic cable be-

tween robot plate and control

panel

Connection at robot or bell plate

is loose

Fiber optic transmitter failure

Bad transceiver module

Excessive vibration

Turbine is not rotating

Fluid valve does not actuate

Clogged fluid tube/fluid tip

Bad transceiver module

Fluid valve open

Fluid valve seat damaged or worn

Insufficient back pressure to fluid

regulator

Fluid regulator does not control

flow (system)

a. Repair or replace fiber optic cable.

b. Bad splice connection or too many

splices. Maximum three (3) splices

permitted.

Re-install cable and tighten locking set

screw.

Replace fiber optic transmitter.

Replace transceiver module.

a. Check bell cup for damage

b. Check bell cup for excessive paint

buildup

c. Insure bell cup is tightened properly

d. Check cup and shaft tapers for clean-

liness

Verify rotation of turbine (the paint

valve air pilot must be interlocked with

the turbine speed feed back signal to

ensure that paint does not flow into the

air bearing).

a. Verify that air pilot signal is present.

b. Fluid valve air pilot pressure is too

low. Increase air pressure to 70 psig

minimum.

c. Replace fluid valve.

Remove and inspect fluid tube or fluid tip.

Replace transceiver module.

a. Remove air pilot signal.

b. If still open, replace fluid valve.

Replace fluid valve seat.

Replace fluid tip with the next smaller

inner diameter size.

Disassemble fluid regulator and inspect

for failed components (system).

General Problem

Possible Cause

Solution

Speed Feedback

Fault

No Fluid Flow

No Fluid Flow

Continuous Fluid

Flow

Uncontrollable

Fluid Flow

MMA-570 Direct/Indirect Charge - Maintenance

Ransburg

LN-9279-13

78