Electrical and fiber optic connections, Fluid connections, Typical installation – Ransburg MMA-570 Direct_Ind Charge Atomizer A13366 User Manual

Page 37: Ransburg

ELECTRICAL AND FIBER OPTIC

CONNECTIONS

The fiber optic connection is made on the back

of the atomizer’s mounting manifold. The fiber

optic cable comes pre-assembled with connec-

tors that are secured in place with a fiber optic

tensioning fitting.

Maximum amount of splices for any length of

cable is 3. The speed detection signal may be

affected if splices are exceeded. Length in any

combination for the fiber optic is 100-feet.

FLUID CONNECTIONS

The paint, solvent, and dump fluid tubing are

connected on the back of the mounting manifold

with plastic fluid fittings. The tubing is made of

PFA. Fluid tubing requirements are shown in “Fluid

Tubing Connection Requirements” chart below.

TYPICAL INSTALLATION

The “Direct and Indirect Charge Typical Instal-

lation” figures in the “Installation” section shows

a typical installation of the applicator with the

MicroPak.

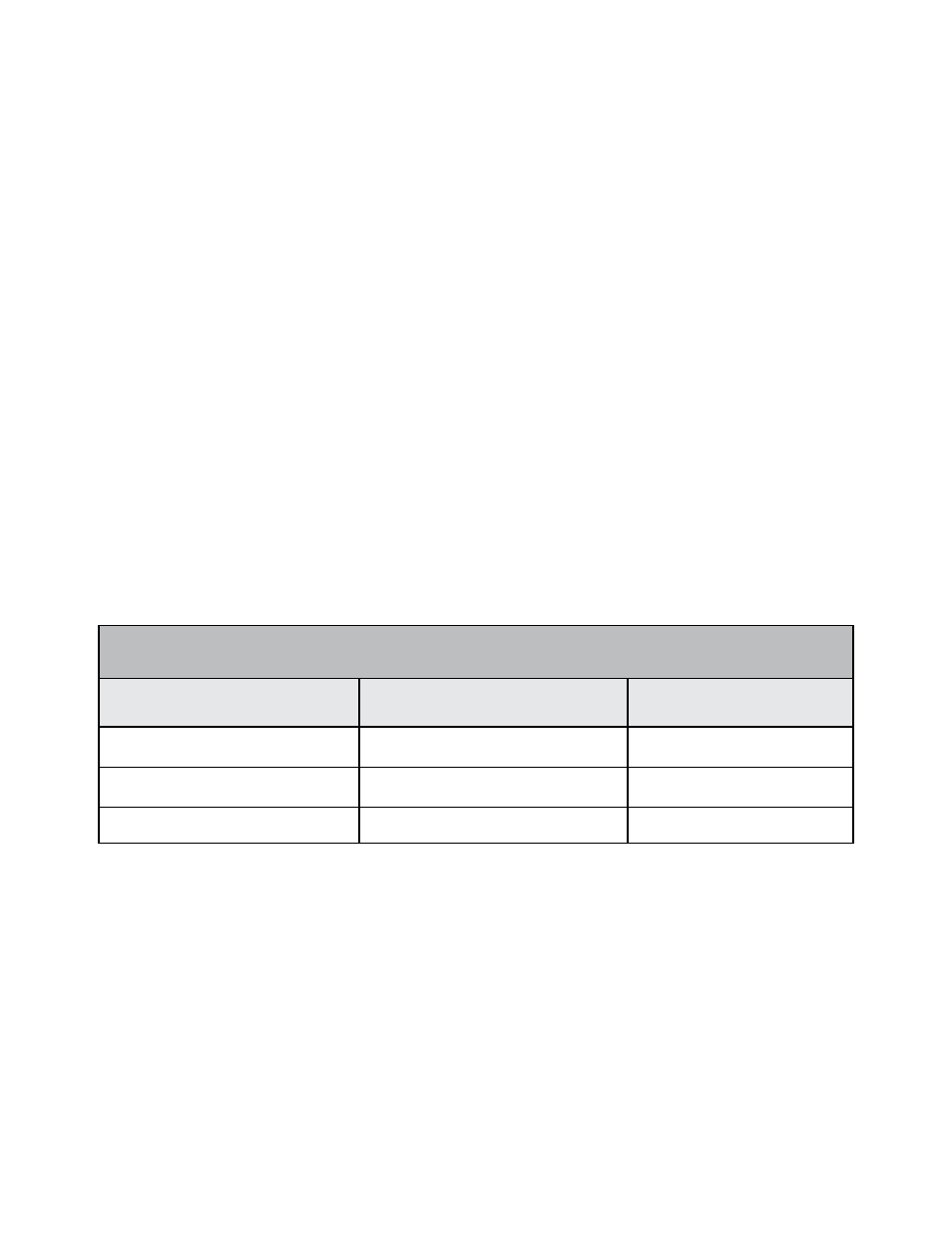

FLUID TUBING CONNECTION REQUIREMENTS

Pressure (Maximum)

Fixed Atomizer

Paint Line (P)

Cup Wash Solvent Line (SOL)

Dump Line (DL)

6mm OD PFA

6mm OD X 4mm ID PFA

8mm PFA or Nylon

200 psi max. (1379 kPa)

150 psi max. (1033 kPa)

200 psi max. (1379 kPa)

MMA-570 Direct/Indirect Charge - Installation

Ransburg

LN-9279-13

34