Ransburg, Mma-570 direct/indirect charge - maintenance – Ransburg MMA-570 Direct_Ind Charge Atomizer A13366 User Manual

Page 72

CHECKING PROBES

Check atomizer voltage using the Ransburg Test

Meter Kit (76652-01 or 76652-04). Verify that the

output voltages have not varied much from the

setup standard. A drastic change in voltage can

be an early indicator of a component or system

problem. The data shown was collected under

the ideal lab conditions using a clean atomizer

and an unloaded fluid delivery system.

The following data is for use with the MMA-570. The

output voltage measured at the bell will normally

range between 91% and 97% of the kV set-point

displayed at the control unit. Typical setting for

spraying is 70 kV.

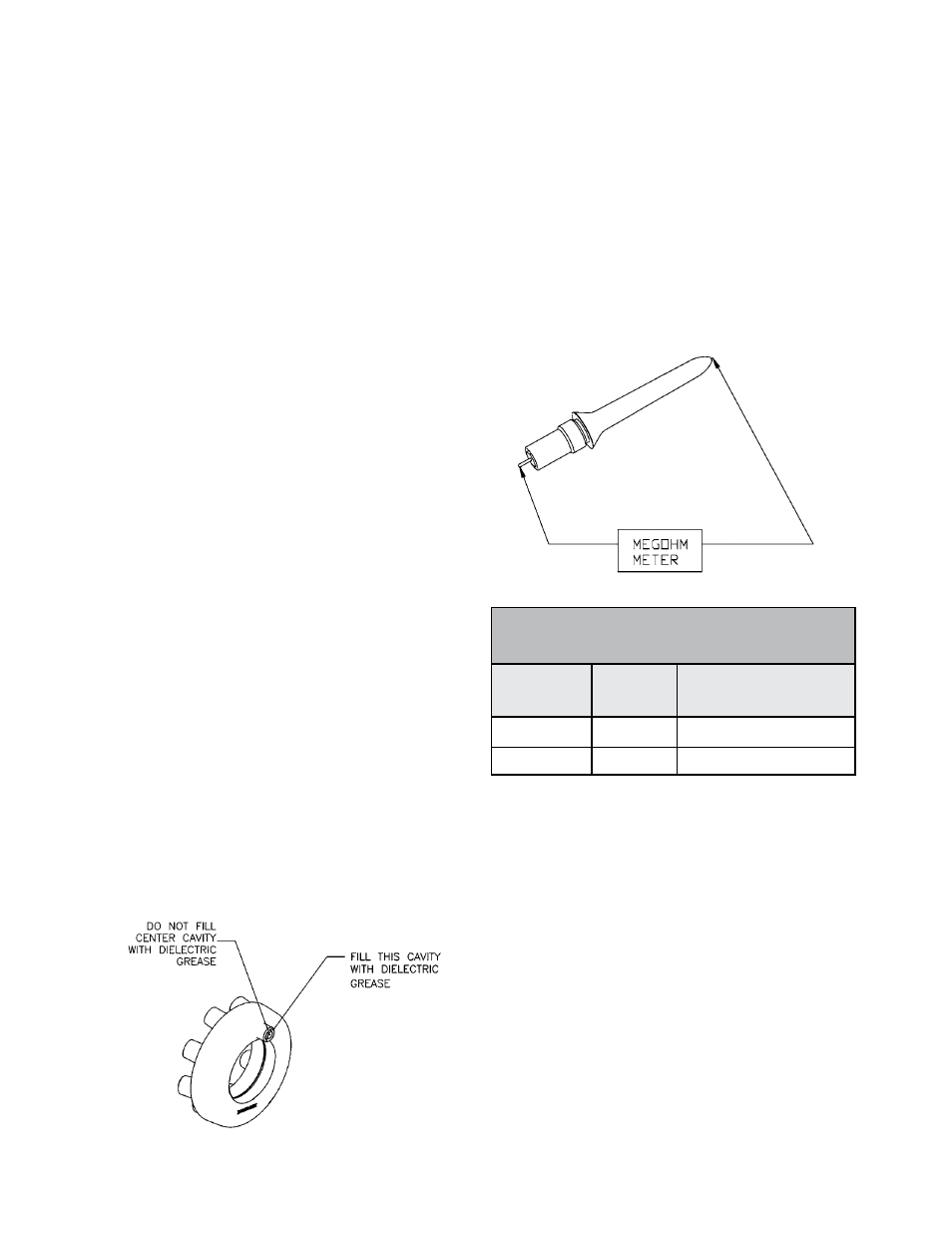

High Voltage Ring Inspection

Examine entire ring for burning marks indicated

by melted plastic or blackened areas around or

near where the electrodes are located, the area

where the high voltage input tube is, and on the

inner diameter of the ring.

If any area is found with the above conditions, the

ring must be replaced.

After verifying, clean all old dielectric grease from

the eight (8) protrusions on the front of the ring

and from the concentric circles at the high voltage

input protrusion.

Re-apply dielectric grease (LSCH0009) to both of

these areas. The eight (8) protrusions only require

a thin film of grease. The high voltage input area

must be filled with grease allowing no air voids.

Excess grease will be squeezed out when the

input tube and high voltage cable are installed.

Wipe off all excess grease.

High Voltage Ring Lubrication

ELECTRODE RESISTANCE TEST

To verify that all indirect charge electrodes are

functioning, place one lead of a Yokogama meg-

ohm meter or equivalent to the metal contact at

the base of the electrode and the other end to

the small metal wire at the tip of the electrode.

Refer to the “Electrode Assembly Resistance

Reading” chart for the proper resistance reading

for the electrode assembly.

If readings fall out of this range, disassemble elec-

trode assembly and check reading of resistor only.

If reading is in the acceptable range, discard the

electrode body (A11342-00) and replace with a

new one. Rebuild electrode assembly as follows:

apply a small amount of dielectric grease to each

end of the resistor, slide resistor into the electrode

body (A11342-00). Install the contact assembly

after the resistor. Finally, apply a small amount of

dielectric grease to contact area of plunger contact

assembly. Thread plunger contact assembly into

electrode body by hand until it stops. Hand-tight

is good enough. Over-tightening will damage

the electrode body (see “Disassembly/Assembly

Electrode Assembly” figure).

A11343-02 209-231 Sea Level

A11343-03 129-151 Above 5,000 ft.

ELECTRODE ASSEMBY

RESISTANCE READING

Part No.

Used At (Locations)

Resistance

Reading

(Megohms)

MMA-570 Direct/Indirect Charge - Maintenance

Ransburg

LN-9279-13

69