Protective covers, Ransburg, Mma-570 direct/indirect charge - operation – Ransburg MMA-570 Direct_Ind Charge Atomizer A13366 User Manual

Page 48

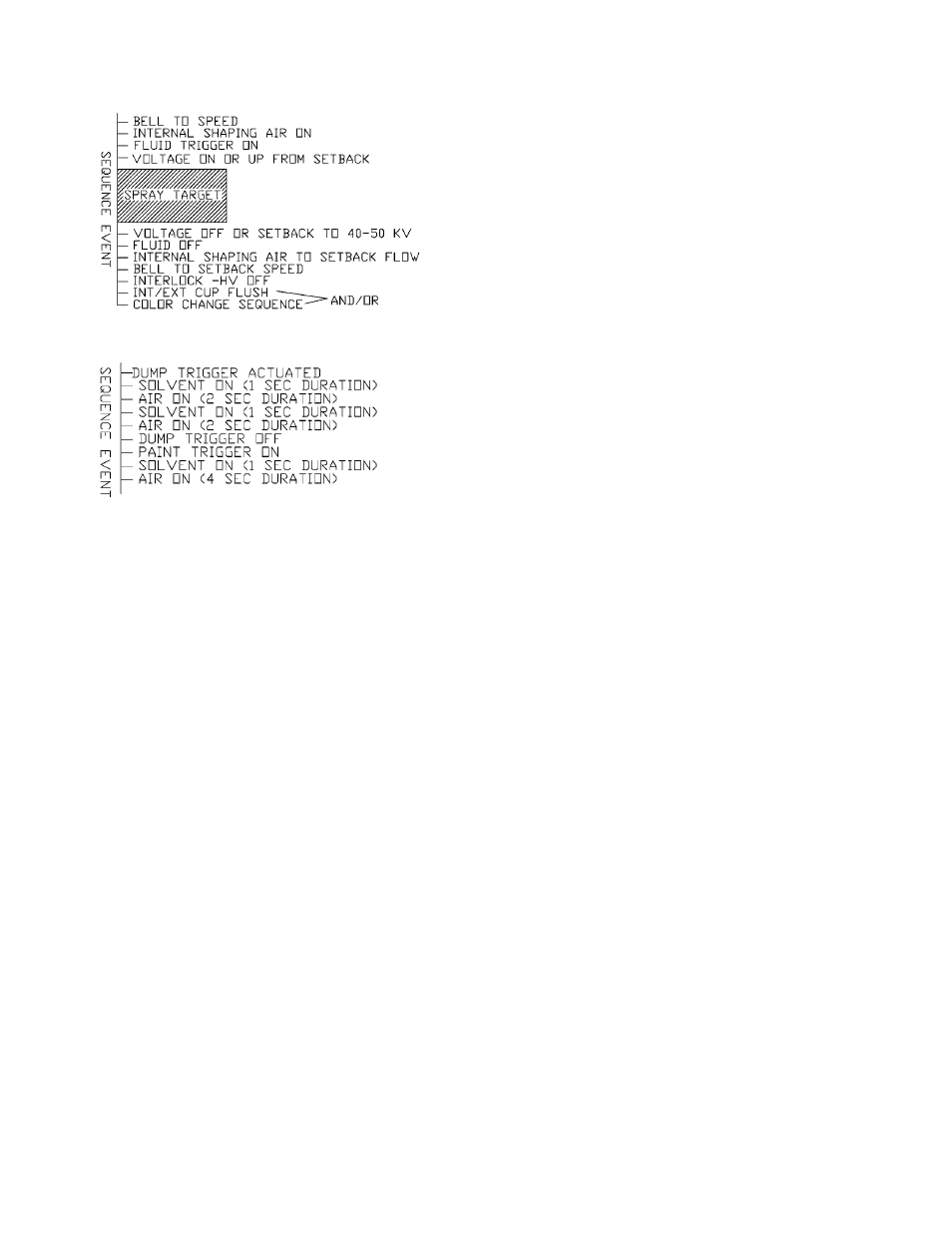

Typical Paint Sequence

Typical Color Change Sequence

Sequence Event Explanation:

1. Bell to Speed - This is accomplished by a set

point command from either the PLC, robot, or

other input device, through the I/O module.

2. Shaping Air - Set to 350-400 SCFM

w h i l e p e r f o r m i n g a c u p f l u s h .

3. Voltage On - The voltage is turned on from

a signal to the MicroPak. The lag time to

full voltage may be reduced if a setback

voltage is used. Recommended setback

voltage is between 30 kV and 50 kV.

4. Trigger Fluid - An air signal is sent through

the PT line of the tubing bundle. This should

occur when the target is 6-12-inches (152.4-

304.8mm) from the applicator centerline.

(Not to be confused with target distance.)

5. Voltage Off/Setback Voltage - Immediately

precedes the trigger off. Using a setback volt-

age shortens the cascade voltage ramp up time.

6. Fluid Trigger Off - This should occur

when the target is typically 0-6-inches (0-

152.4mm) past the applicator centerline.

7. Shaping Air to Setback - The setback

flow of air should never be below 70 slpm

(2.6 SCFM) for the inner shape air except

when performing a cup flush sequence.

8. Color Change Sequence - Used when

color is changed one to the other. Typical

sequence is shown in “Typical Color Change

Sequence” figure in the “Operation” section.

(Note: During this sequence, the applicator

should be moved to a position to collect

the waste material.) The sequence shown

is a starting point for processing, but the final

sequence will depend on the material being

sprayed and the solvent used to purge the

applicator with.

PROTECTIVE COVERS

It is recommended to use covers to reduce the

amount of overspray build-up on the shroud and

electrodes. Two covers are available, a white lint

free stretch cloth for covering the probes and a foam

cover (green) for the front shaping air shroud. The

white cloth cover should cover all of the electrode

except for the last 1-inch (25-4mm). The green

foam cover should be installed until just past the

radius edge of the shroud. Care is to be taken

when installing the white cloth covers over the

electrodes, do not bend them. (Devise a fixture

to help slide the cover over easier.).

When cleaning, do not get covers wet, it will attract

more overspray, more quickly. Push them back,

clean surface, dry thoroughly, and slide back to

original position. Depending on conditions, covers

should be replaced after each shift (8 hours).

A11565-00 White Stretch, Lint Free Covers

A11564-00 - Foam Elastic Covers (Green)

MMA-570 Direct/Indirect Charge - Operation

Ransburg

LN-9279-13

45