Ransburg, Mma-570 direct/indirect charge - maintenance – Ransburg MMA-570 Direct_Ind Charge Atomizer A13366 User Manual

Page 54

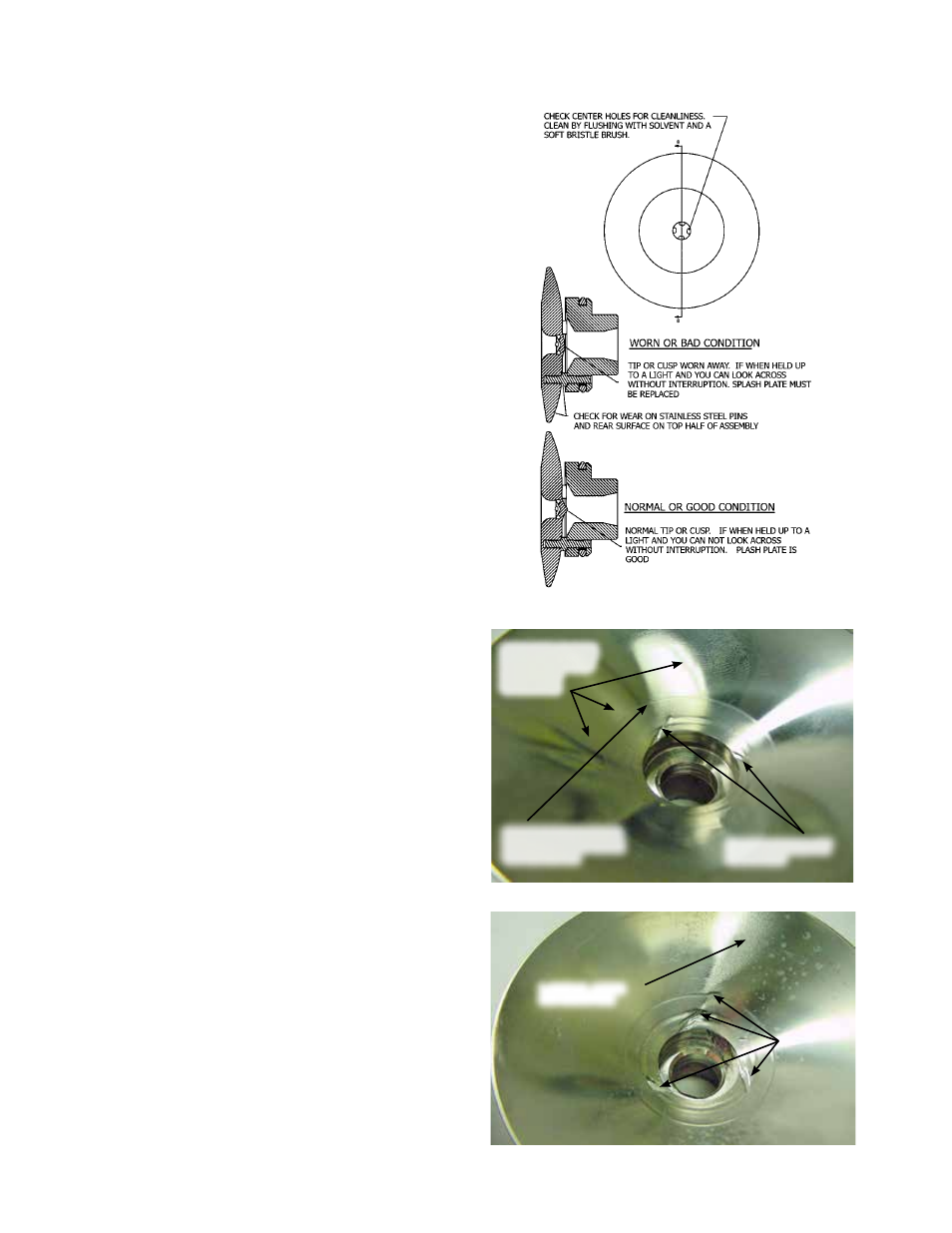

Bell Cup Replacement

Bell cup wear is dependent on many factors such

as bell speed, flow rate, and type of coating being

applied.

The bell cups shown in the photos indicates if a bell

cup has some useable life or should be replaced.

Photo 1 shows a bell cup that has some useable

life. The grooves worn around the splash plate

pins are shallow. The general appearance of the

cup surface is smooth and uninterrupted. Photo

2 shows a bell cup that needs to be replaced, as

well as the splash plate that was installed into the

cup. The grooves are deep, a visible groove exists

at the outer edge diameter of the splash plate and

there are noticeable lateral grooves extending

towards the outer edge of the cup.

Photo 1

Photo 2

LATERAL LINES

OR GROOVES

DEEP

GROOVES

SMOOTH CLEAN

UNINTERUPTED

BELL CUP

SURFACE

LIGHT VISIBLE WEAR

NEAR SPLASH PLATE

OUTER EDGE

SLIGHT, SHALLOW

GROOVES

6. Splash plate assemblies may be soaked for a

short time, under 2 hours, to loosen dried ma-

terial. Clean with a soft bristle brush. Blow out

center holes to dislodge material. Never use

any kind of pick instrument to clean these holes.

7. Soaking the bell in solvent may aid in

loosening or removing paint build-up. It

is recommended that the splash plate

be removed and cleaned separately.

8. Use a soft bristle brush dipped in solvent

to remove paint build-up from the serra-

tion cuts, paint feed holes or slots, and

external and internal surfaces of the bell.

9. A soft, lint free rag dampened with solvent

may be used to remove any paint residue from

the external and internal surfaces of the bell.

10. After removing all paint build-up or residue,

rinse the bell in clean solvent and blow dry.

11. Before reinstalling the bell on the shaft, check

the mating surfaces of the thread and taper for

any paint build-up or residue. Also, check the

fluid tip, fluid tube outside diameter, and the shaft

for any further paint build-up. These surfaces

should be cleaned before installing the bell.

12. It is recommended that extra bell cups be

purchased. The cups can then be cleaned

off line in an automated cup cleaner.

13. Reinstall cups to proper torque 50-70 lbs•in

(5.65-7.91 Nm).

Inspection of Bell Cups

s

MMA-570 Direct/Indirect Charge - Maintenance

Ransburg

LN-9279-13

51