General Tools and Instruments GTi10-20-30-50 User Manual

Page 62

62

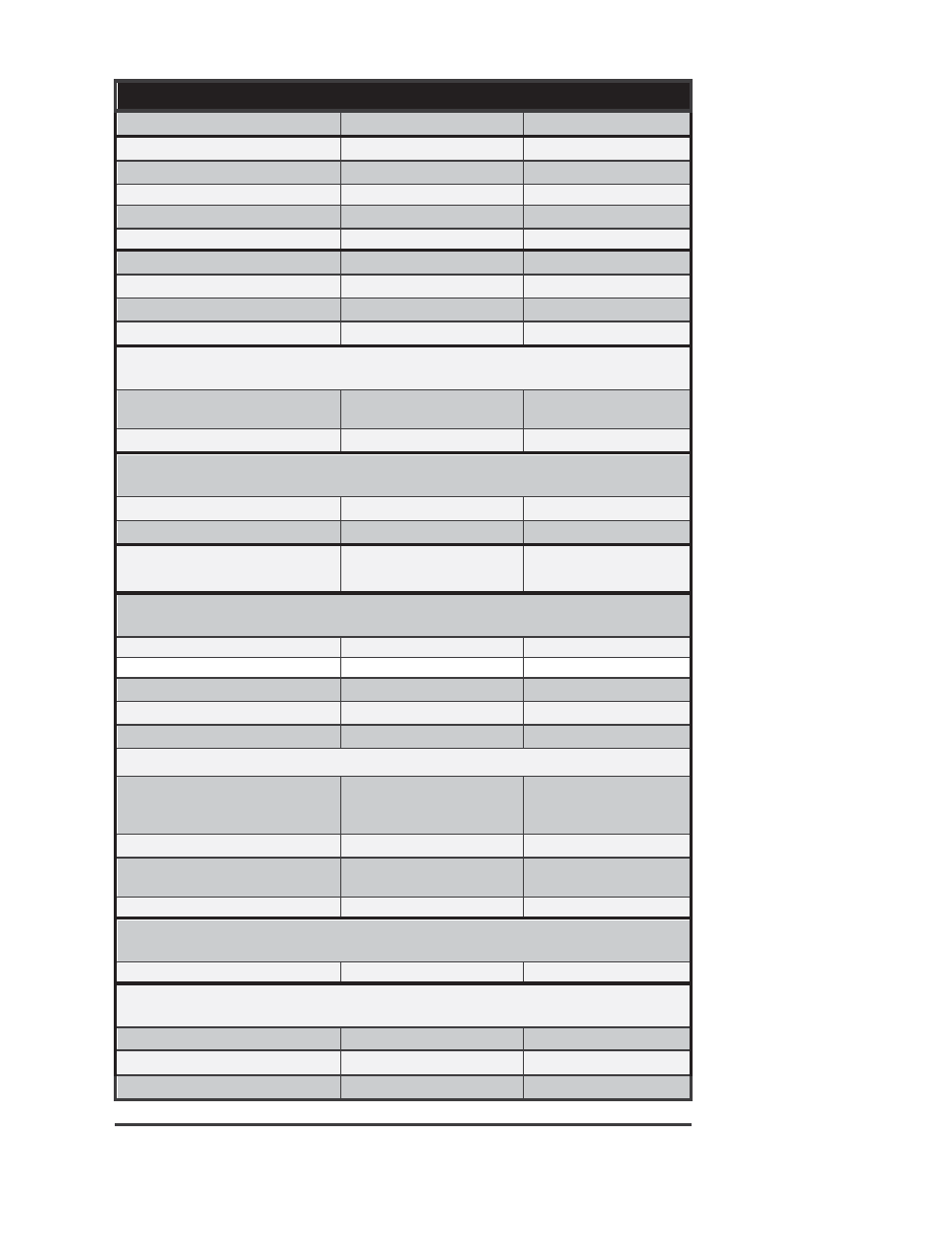

Emissivities of Common Materials (Con’t)

Material

Temperature

°C

Emissivity

Electrolytic ferric oxide

500

1200

0.85

0.89

Iron plate

925

1120

0.87

0.95

Cast iron, heavy ferric oxide

25

0.80

Tempered iron, ferric oxide

40

250

0.95

Melting surface

22

0.94

Melting cast iron

1300

1400

0.29

Melting mild steel

1600

1800

0.28

Liquid steel

1500

1650

0.42

0.53

Pure liquid iron

1515

1680

0.42

0.45

Lead

Pure lead (Non-

oxidization)

125

225

0.06

0.08

Mildly oxidized

25

300

0.20

0.45

Magnesium

Magnesia

275

825

0.55

0.20

Magnesia

900

1670

0.20

Hg

0

100

0.09

0.12

Nickel

Electroplate polishing

25

0.05

Electroplate non-polishing

20

0.01

Nickel wire

185

1010

0.09

0.19

Nickel plate (oxidized)

198

600

0.37

0.48

Nickel oxide

650

1255

0.59

0.86

Nickel alloy

Nickel-chrome (heat-

resistance) alloy wire

(shining)

50

1000

0.65

0.79

Nickel-chrome alloy

50

1040

0.64

0.76

Nickel-chrome (heat

resistance)

50

500

0.95

0.98

Nickel-silver alloy

100

0.14

Silver

Polished silver

100

0.05

Stainless steel

18-8

25

0.16

304(8Cr,18Ni)

215

490

0.44

0.36

310(25Cr,20Ni)

215

520

0.90

0.97