FEC AFC1500 User Manual

Page 41

AFC1500 Multi-2 Unit Hardware Manual (Rev. 2)

PAGE 4 - 17

Chapter 4: Installation & Wiring

(Output Signals – Continued)

In addition to the main Multi unit output signals, individual spindles that are connected to the Multi unit

report status signals to the Multi Unit. These signals are available on a “per spindle” basis and can

be used or programmed using the AFC User Console software.

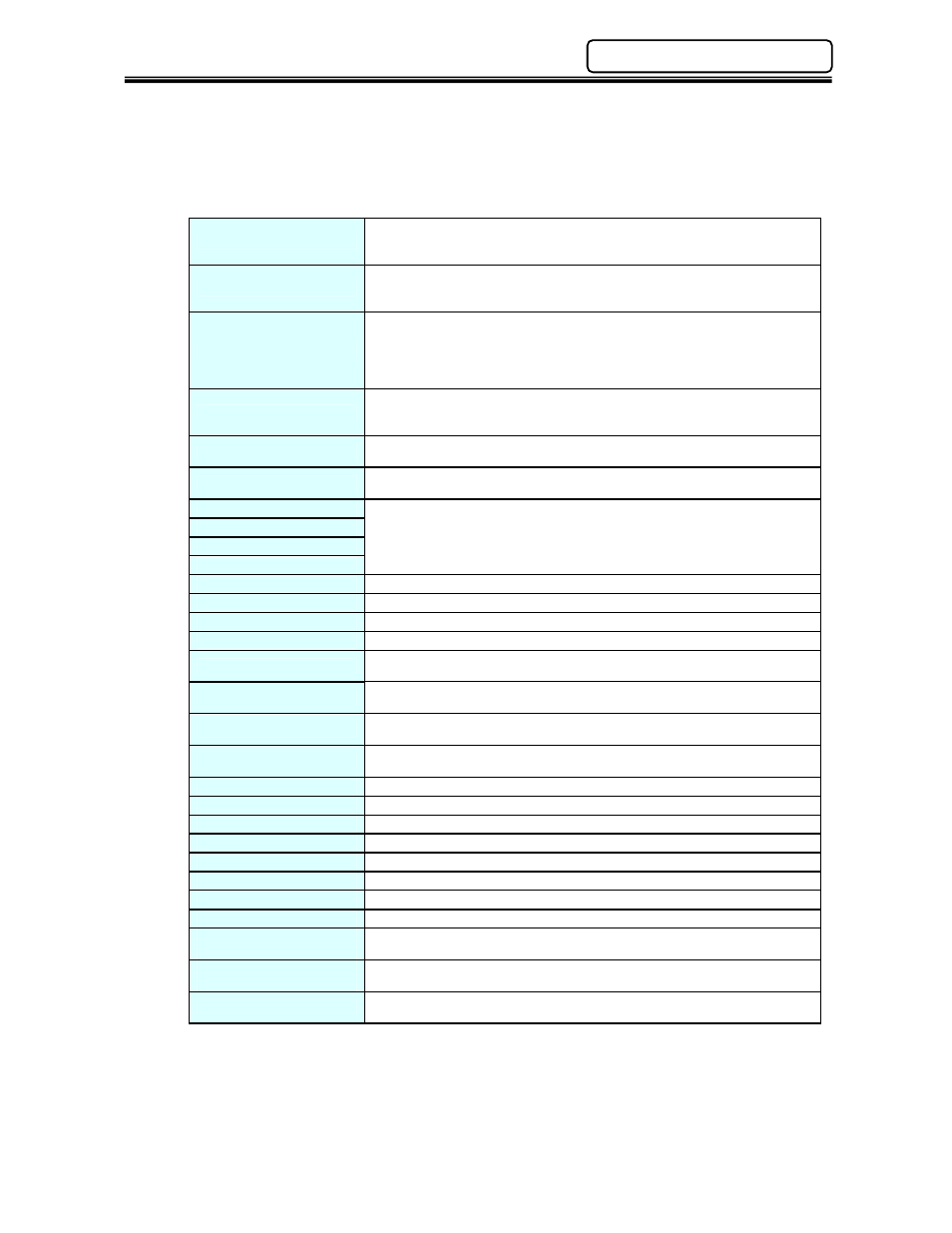

Available Individual Spindle Unit Output Signals (Per connected spindle)

Reject

Output when the fastening result is a REJECT. Indicates that the spindle has

failed achieving the fastening limits. This output remains active until the

START signal or RESET signal is input.

Accept

Output when the fastening result is an ACCEPT. Indicates that the spindle is

within fastening limits. This output remains active until the START signal or

RESET signal is input.

Abnormal

Output when an Abnormal condition occurs. This signal indicates that the

spindle has detected an internal fault and can no longer proceed. The fault

maybe generated during a self-check function (see AFC1500 Operation

Manual for troubleshooting). The RESET signal clears the abnormal

condition.

Ready

Output when the spindle is in the READY condition. Indicates spindle is

ready to operate and inputs are enabled. This signal is inactive (off) when the

BUSY output is active (on).

Busy

Output after a START signal is received, and remains active until the

fastening cycle is complete and the READY signal is output.

Bypass

Signal is active when the spindle is bypassed either from San Unit bypass

input signal or from the San Unit bypass switch.

Parameter Select 1

Output confirmation of PARAMETER SELECT 1~4 input selections.

Parameter Select bits are active according to what sequence is set from the

sequence select inputs.

Parameter Select 2

Parameter Select 3

Parameter Select 4

Time 1 Low Reject

Output when 1

st

Time result is below the set 1

st

Time Low Limit value.

Time 1 High Reject

Output when 1

st

Time result is above the set 1

st

Time High Limit value.

Time 2 Low Reject

Output when Final Time result is below the set Final Time Low Limit value.

Time 2 High Reject

Output when Final Time result is above the set Final Time High Limit value.

Peak Torque Low Reject

Output when Peak Torque result is below the set Peak Torque Low Limit

value.

Peak Torque High Reject

Output when Peak Torque result is above the set Peak Torque High Limit

value.

Final Torque Low Reject

Output when Final Torque result is below the set Final Torque Low Limit

value.

Final Torque High Reject

Output when Final Torque result is above the set Final Torque High Limit

value.

Angle Low Reject

Output when Angle result is below the set Angle Low Limit value.

Angle Low Reject

Output when Angle result is above the set Angle High Limit value.

Rate 1 Low Reject

Output when Rate 1 result is below the set Rate 1 Low.

Rate 1 High Reject

Output when Rate 1 result is above the set Rate 1 High.

Rate 2 Low Reject

Output when Rate 2 result is below the set Rate 2 Low.

Rate 2 High Reject

Output when Rate 2 result is above the set Rate 2 High.

Rate 3 Low Reject

Output when Rate 3 result is below the set Rate 3 Low.

Rate 3 High Reject

Output when Rate 3 result is above the set Rate 3 High.

Current Limit Low

Warning

Output when the current is below acceptable Limits.

Current Limit High

Warning

Output when the current is above acceptable Limits.

Combination Bits 1-8

Used to create “special” outputs formed by using a combination of SAN Unit

outputs in “AND / OR” logic.