FEC AFC1500 User Manual

Page 26

AFC1500 Multi-2 Unit Hardware Manual (Rev.2)

PAGE 3 - 4

Chapter 3: System Description

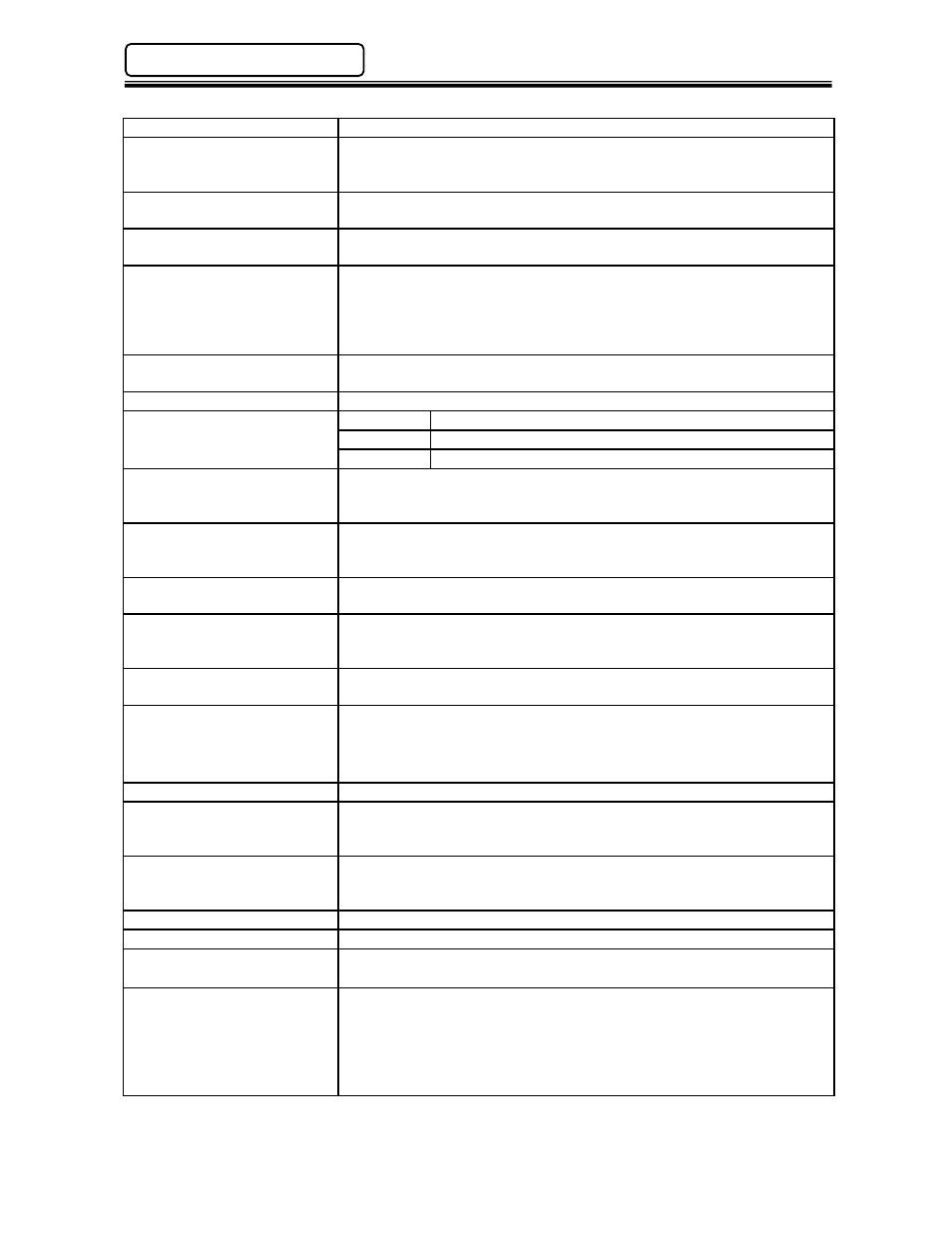

Multi-2 Unit Panel Description

Power On LED

Indicates when power is applied to the Multi-2 Unit.

Busy LED

Lights when the unit is performing a self check, return, fastening

operation or is downloading/uploading data to the AFC User Console

software package.

Accept LED

Lights if a fastening cycle or a self check test falls within acceptable

parameters. (This LED indicates status for ALL connected spindles)

Reject LED

Lights if a fastening cycle or a self check test is outside of acceptable

parameters. (This LED indicates status for ALL connected spindles)

Abnormal LED

Lights when a system abnormal condition is detected in the control

system of any connected spindle. (Does NOT indicate a spindle reject).

All operations are halted and cannot be restarted until the Abnormal

condition is corrected. Can be cleared only by the Reset function. (see

AFC1500 Operation Manual for Abnormal Troubleshooting)

RS485 Port

RJ45 style connector used to connect to all AFC1500 Servo (SAN)

Units included in the system.

Ethernet U/C Port

Communication port for the AFC Software User Console PC.

Ethernet U/C Status LEDs

Red

(TX) Transmitting Data

Yellow

10/100 Link

Green

(RX) Receiving Data

Reset Button

Resets all signal and communication buffers to “clear” conditions.

Clears the Abnormal signal and performs the Torque Transducer Zero

Level Check.

Start Button

Starts the fastening cycle. Requires a pulse of 0.1 to 0.5 sec. for

“Normal” start selection or must be maintained during complete cycle

for “Deadman” start selection.

Reverse Button

Turns the spindles in the opposite direction of the preset fastening

direction while the button is held active.

Cal Button

Performs the Torque Transducer shunt calibration test. When pressed,

the Servo (SAN) Units will display either a green accept LED or red

reject LED indicating status of the individual Calibration test.

Power Connector

Connects to incoming power: 100 to 220VAC (auto-sensing), Single

phase, 50/60 Hz.

Interface Board (I/O)

Allocation socket for input/output signal Interface boards. Options

available are Discrete I/O (Sink or Source), Interbus-S

®

, DeviceNet

®

,

Profibus

®

, CC-Link

®

(Version 1 or 2), Modbus Plus

®

, Allen Bradley

Remote I/O (Rockwell License #199906006) or Ethernet-I/P

RS232C – PC Port

Communication port for the User Console PC.

RS232C – Data Out Port #1

(RS232C – Data Out Port)

Communication port for fastening result data output to any external

device, i.e.: host computer, serial printer, etc. Data output format is

configured using the User Console (AFC) Software package.

RS232C – Data In Port

Communication port for ASCII data input from peripheral devices. (Ex:

bar code readers, RF tag, etc.) Allows external ASCII data to be merged

with fastening result data.

RS232C – Data Out Port #2

Not Used

RS422 – Display Port

Not Used

Ethernet Network Port*

for network connectivity (Toolsnet

®

, QDAS

®

, SQL, Custom Protocol,

etc.)

Ethernet Reset Button*

For resetting the Network Ethernet Port IP address to default setting.

(IP: 192.168.10.40 Subnet Mask: 255.255.255.0 Gateway:

192.168.10.1)

To reset port to default IP address, power down Multi Unit. Depress

reset button and hold it depressed while powering on the Multi Unit until

green Accept LED illuminates.

*On Ethernet Version only.