FEC AFC1500 User Manual

Page 34

AFC1500 Multi-2 Unit Hardware Manual (Rev. 2)

PAGE 4 - 10

Chapter 4: Installation & Wiring

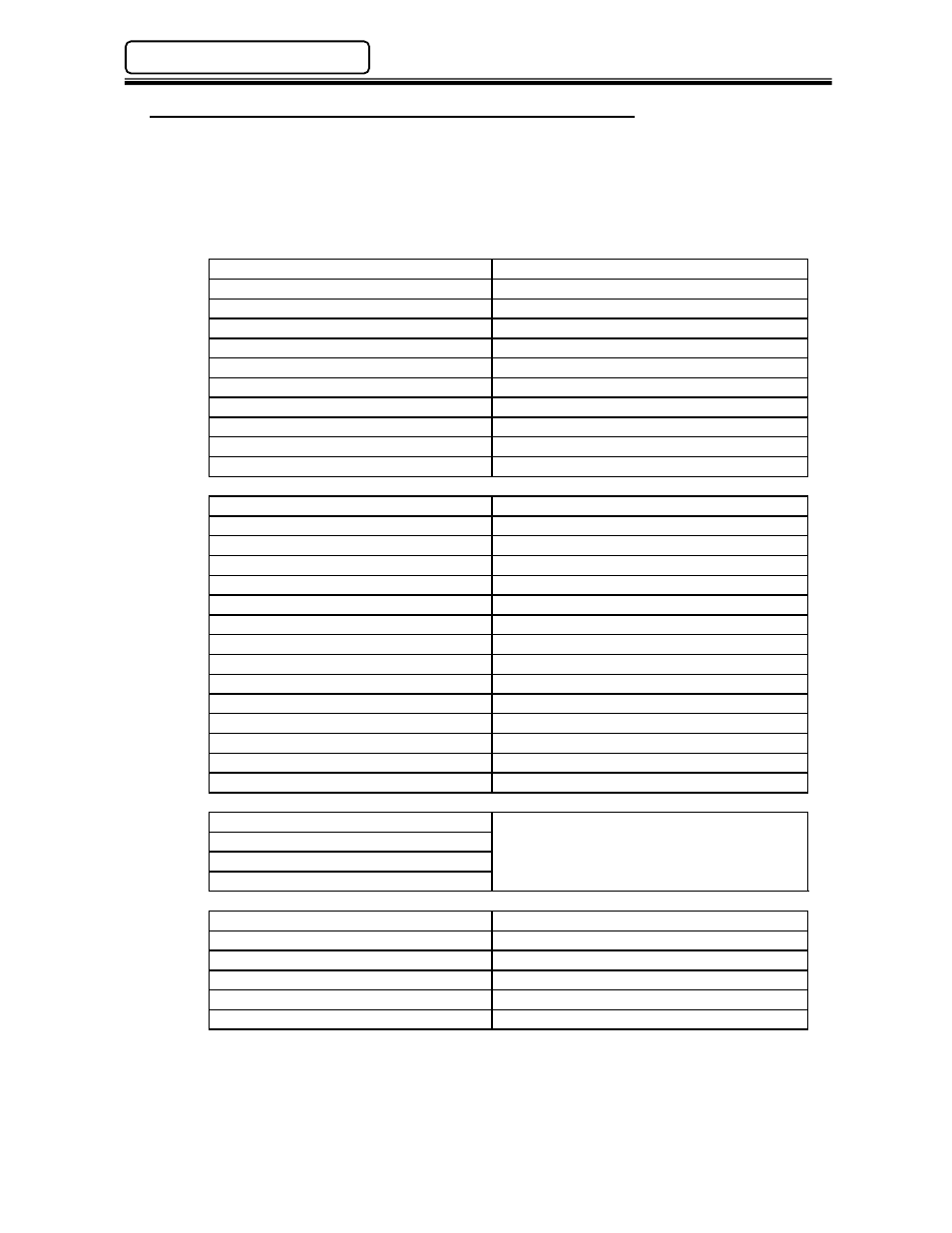

4.6.3.1 Available Output Data (From DATA-OUT 1 Port)

The Multi-2 Unit is capable of outputting the fastening results data in an ASCII format to a serial

printer or other serial peripheral devices. The data is sent from the Multi-2 Unit’s RS232C “DATA

OUT - 1” port. The output data string format as well as port configuration can be configured using

the AFC User Console Software. As little as one data item or up to all items can be user

configured. ASCII Control Characters may also be implemented (Ex: Start of Text, End of Text,

etc.). Below is a list of data available and its byte length.

Basic Fastening Data

Length in bytes

Peak Torque

6

Final Angle

5

First Time

6

Final Time

6

Cycle Time

5

First Torque Rate

7

Second Torque Rate

7

Third Torque Rate

7

Final Torque

5

Offset Torque

5

Judgment

3

Extended Fastening Data

Length in bytes

Current (@ peak torque)

4

Angle (@ peak torque)

4

First Peak Torque

5

Second Peak Torque

5

First Torque Rate Increment Torque

5

First Torque Rate Increment Angle

4

Second Torque Rate Increment Torque

5

Second Torque Rate Increment Angle

4

Third Torque Rate Increment Torque

5

Third Torque Rate Increment Angle

4

Rundown revolutions

4

Cal Voltage Value

5

Zero Voltage Value

5

Judgment

2

Retry Flag

3 (ASCII “RTY”)

Input Data*

Length in bytes

RS232C data buffer 1

Up to 128

This length is determined by the user and

dependent upon the length of data input to

these data areas.

RS232C data buffer 2

RS232C data buffer 3

RS232C data buffer 4

System Data

Length in bytes

Date

10

Time

8

Spindle Number

2

Sequence Number

2

Parameter Number

2

Cycle Count Number

7

*Input Data is input to the Multi-2 Unit using the RS232C “DATA INPUT” port. This port is

configured through the AFC User Console Software. The data must be ASCII formatted data & is

limited to 128 bytes in (4) separate data buffers. The port must be configured for the input string

which is to be received. The data received can then be married with the resultant fastening data by

selecting the RS232 data in the output format. This function is typically used to marry a part

number with the resultant fastening data for production birth history.