FEC AFC1500 User Manual

Page 20

AFC1500 Multi-2 Unit Hardware Manual (Rev.2)

PAGE 2 - 2

Chapter 2: Specifications

2.1 Specifications

Power Supply Voltage

100 to 220 VAC±15%, 1-phase, 50/60 Hz.

Power Consumption

9 Watt/Hour

In rush current

Less than 160 mA

CPU

NEC V53A

Data Communication

RS232C (User Console PC) (N/A with Ethernet Data Option)

RS232C (Data Output #1 / Data Output)

RS232C (Data Input)

RS232C (Data Output #2)

(N/A with Ethernet Data Option)

RS422 (External Remote Display)

RS485 Servo Units Programming/Control

Ethernet - User Console (User Console PC)

Ethernet - Network Communication (OPTIONAL 2E Version Only)

Control Interfaces

Discrete I/O (24Vdc Sink)

Discrete I/O (24Vdc Source)

DeviceNet

®

(Includes data messaging capability)

Profibus

®

Profinet IO

Ethernet I/P

(Includes data messaging capability)

Mitsubishi CC Link

®

1

Allen Bradley Remote I/O

1

Modbus Plus

®

CC Link

®

Version 2

(Includes data messaging capability)

Interbus-S

®

M-Net

Additional Interfaces also available:

Contact FEC for special fieldbus requirements

Fastening Sequence

Programming Steps

100

(99 plus “End” Step)

Fastening

Control Methods

Torque Control / Angle Control

Optional Yield Control (Requires SAN Ver. 2.39)

Max. No. of spindles

31 per Multi-2 Unit

Fastening Parameters

16

Fastening Sequences

16

Torque Rate

monitoring areas

3

(1

st

, 2

nd

and 3

rd

Rate areas)

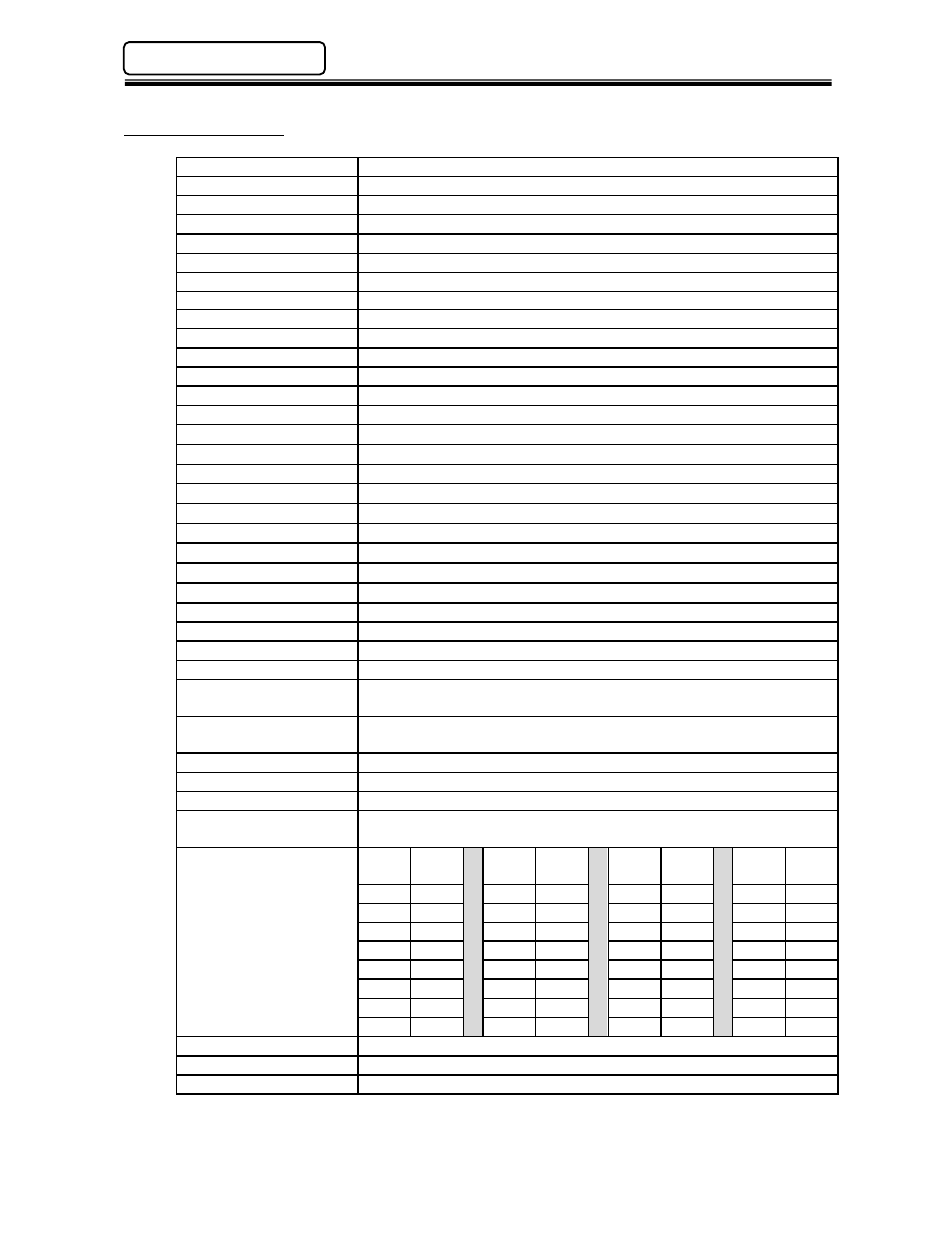

Data Storage

(Non-volatile RAM)

Based on the number of

spindles connected.

2

# of

Spdls.

Stored

Cycles

# of

Spdls.

Stored

Cycles

# of

Spdls.

Stored

Cycles

# of

Spdls.

Stored

Cycles

1

7878

9

2288

17

1326

25

936

2

6032

10

2080

18

1248

26

910

3

4888

11

1924

19

1196

27

858

4

4108

12

1794

20

1144

28

832

5

3536

13

1690

21

1092

29

806

6

3120

14

1586

22

1040

30

780

7

2782

15

1482

23

1014

31

754

8

2496

16

1404

24

962

Installation requirement NEMA12 Enclosure

Operation Temperature 0º to 50 ºC (32 º to 122 ºF)

Operation Humidity

20% to 90%

1) Mitsubishi CC Link & Allen Bradley Remote I/O are proprietary and licensed for use.

2) The number of cycles stored will be reduced if RS232C - DATA IN data is stored with the

fastening data.