Boom slider pad adjustment, How to check and tighten boom hoses – Gradall 534B (9103-1390) Service Manual User Manual

Page 90

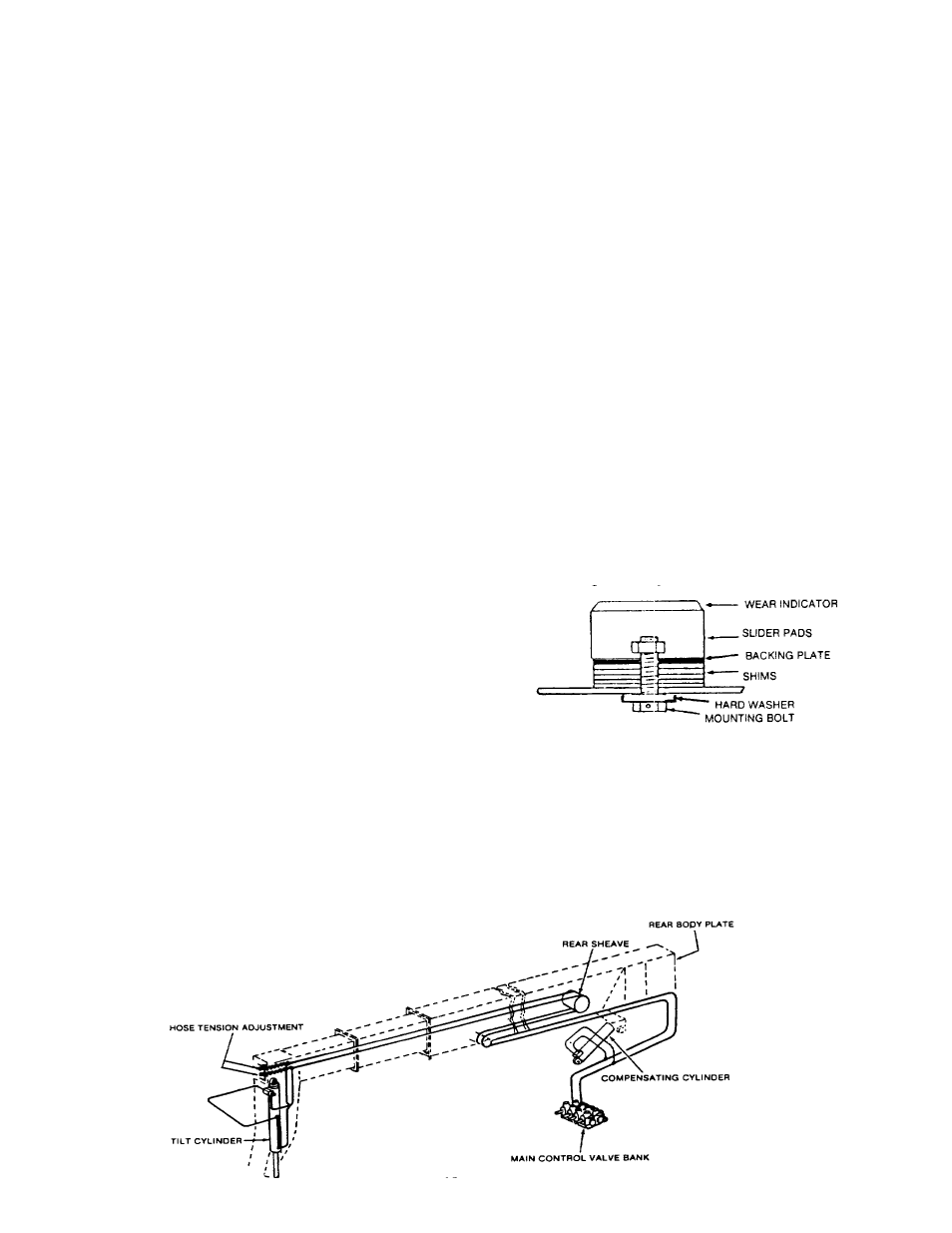

BOOM SLIDER PAD ADJUSTMENT

Slider pads are used between boom sections. If

excessive clearance appears between the boom sec-

tions, pads should be adjusted by shimming.

HOW TO TEST PADS

FOR EXCESSIVE CLEARANCE

(OVER 1/16") BETWEEN BOOMS

To test the boom clearance, extend the boom fully

and place the head or the attachment on the ground.

Raise and lower the boom slowly and observe the

clearance between the pads and the boom sections.

Also inspect the mating surface of each of the top

and bottom pads. These pads are beveled on the

sides. When they wear down to a point where there

is no more bevel, they should be replaced.

If adjustment is called for, shims should be added to

bring the pads back into close contact with the

adjacent boom. Add shims until no more shims can

be added.

The hoses carrying oil to the front of the main boom

are adjusted at the bottom front of the main boom. To

keep them against the sheave assemblies, tensioning

devices are clamped to each hose.

PROCEDURE FOR INSTALLING

BOOM BEARING RETAINING BOLTS

Shim bearing to proper fit.

When installing bearing retaining bolt, make sure

end of bolt is not sticking out of bearing insert to the

point where it would be in the bearing wear area. To

achieve this, you may have to use washers under the

heads of the bolts as shims. If this causes the bolt

heads to hit other boom bearings exchange these

bolts for ones of correct length.

3/8" bearing retainer bolts should be installed with

blue loctite and then torqued to 30-35 ft./lbs.

1/2" bearing retainer bolts should be installed with

blue loctite and then torqued to 68-78 ft./lbs.

When rechecking bolts at correct torque after loctite

has set they should not turn.lf they do turn more than

360 they must be removed and blue loctite reapplied.

NOTE: When removing bearing pad bolts to

reapply loctite only remove one bolt at a time.

Reinstall the bolt and tighten before removing

another bolt. This prevents the shims or bearing pad

from falling out of place.

l

l

l

l

l

HOW TO CHECK AND TIGHTEN

BOOM HOSES

Remove the rear main boom plate visually

inspect, using a flashlight, to see if the hoses are tight

against the rear sheave. If there appears to be slack

in the hoses, tighten them by turning in on the

adjusting nuts. Loosen the jam nut and tighten as

required. When proper tension is obtained, tighten

the jam nut and replace the rear plate.

13