How to test and adjust main control valve relief – Gradall 534B (9103-1390) Service Manual User Manual

Page 82

TESTING HYDRAULIC RELIEF

VALVE PRESSURES

The reason for testing the main relief valves is to

assure that the relief valves open and to limit the

pressure in the lines at that time.

A. The engine should be turning at full governed

rpm.

B. The hydraulic oil should be warmed up to

operating temperature.

C. The test gage or gages should be installed in the

circuit being tested.

D. The circuit function should be stalled by either

running the cylinder to the end of its stroke or by

stalling the motor action.

E. With the control levers actuated, a gage reading

is taken. The gage indicates the setting of the

respective relief valve.

Circuit relief valves are used in some circuits to

protect Gradall Material Handler from external

forces.

Other relief valves are installed in the circuit to limit

the pressures for that circuit or to control flow

during specific actions.

NOTE

Park Material Handler on level ground with

forks on ground. Shut off engine, set parking

brake and remove ignition key. Chock the

wheels belore pertorming any servicing.

ADJUSTING RELIEF VALVES

All of the relief valves can be adjusted using an allen

wrench or a screwdriver. Loosen the lock nut, and

turn the adjusting screw clockwise to increase the

prssures. Turning it counter-clockwise will

decrease the pressures. The valve adjustment is

sensitive, so adjust in smalll moves, like 1/8 to 1/4

turn at a time. Tighten lock nut after adjustment.

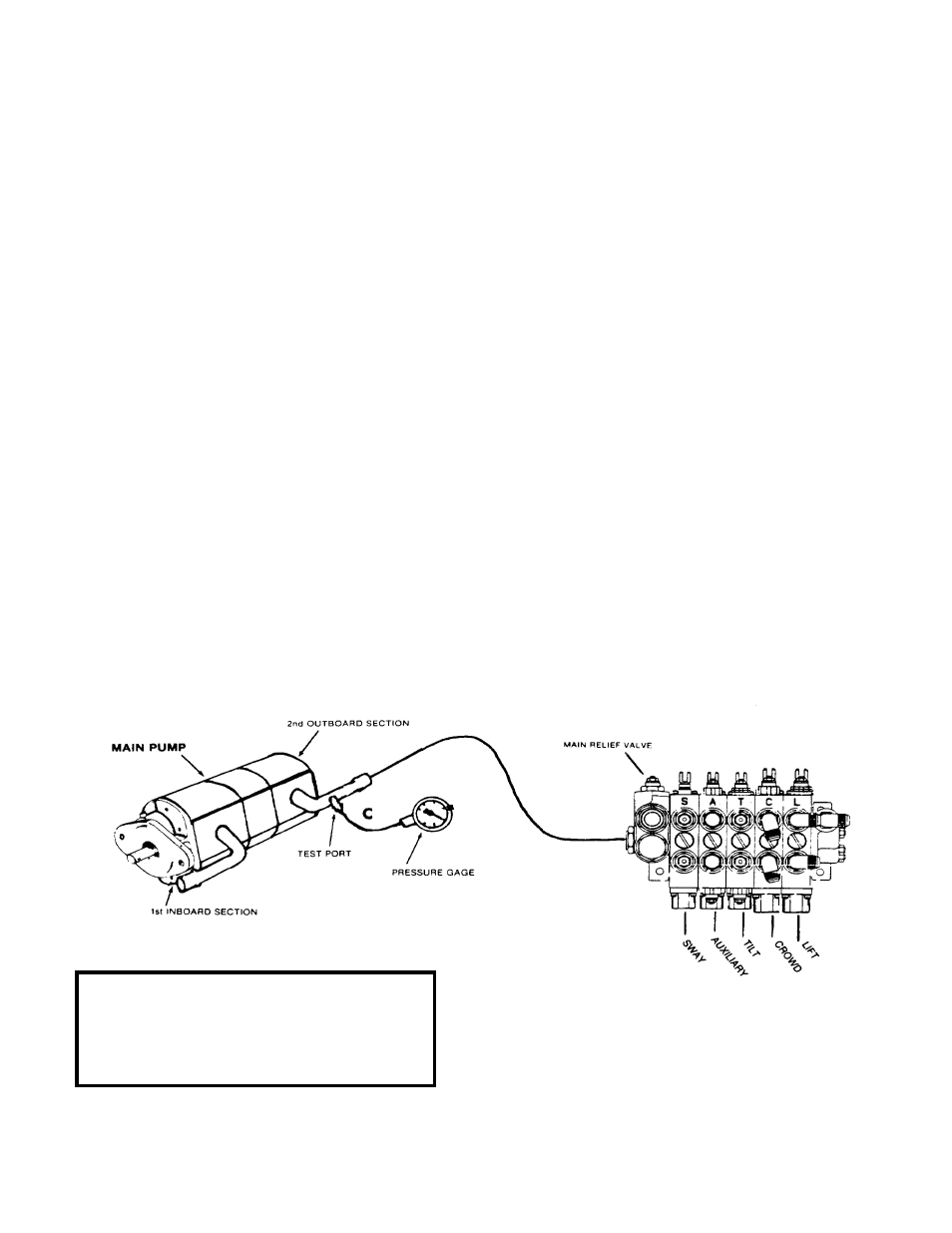

HOW TO TEST AND ADJUST

MAIN CONTROL VALVE RELIEF

Set pressures with oil at operating temperature and

engine at 2800 rpm.

1. Install gage in test port on tandem pump out-

board tube. (C)

2. Retract boom fully and hold control lever full

to left.

3. Gage should read 3000 psi.

4. Adjust, reseal or replace relief valve, as

necessary.

5. Remove gage and recap test port.

If adjustment of the relief valve will not provide

desired pressure readings:

1. Replace pressure gage.

2. Test or examine other components in the circiut

being tested.

3. Replace defective component.

5