Pressure bleeding instructions, Bleeding procedures, Bench bleeding instructions – Gradall 534B (9103-1390) Service Manual User Manual

Page 76

PRESSURE BLEEDING

INSTRUCTIONS

Master Cylinder must be mounted to

power assist section.

Fill reservoir with proper fluid.

Be certain all fittings are tight to avoid

leaking.

DO NOT DEPRESS PEDAL.

Connect pressure bleeder into

reservoir adapter. Recommended

bleeding pressure is 2.07 bar

(30 psi) maximum. NOTE: Make

sure to use correct pressure

bleeder for type fluid used in

system.

Open bleeder screw closest to

master cylinder outlet. Most of the

air contained in the system will

escape by this route. Close bleed-

er screw.

Continue to the next bleeder

screw and so on. At each point

when air bubbles disappear close

bleeder screw.

Remove pressure bleeder.

Open bleeder screw at master

cylinder. Actuate cylinder to re-

move any residual air. Tighten

bleeder screw before permitting

pedal to return.

Actuate pedal several times. If

pedal is spongy, check for system

leaks and repeat bleeding process.

Form No. 81-460-159

BLEEDING PROCEDURES

NOTE

Use only proper fluid specified by vehicle manufacturer. Never reuse fluid that has been drained from the system.

Be sure that you maintain a high level of fluid in the reservoir during and after the entire bleeding process.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

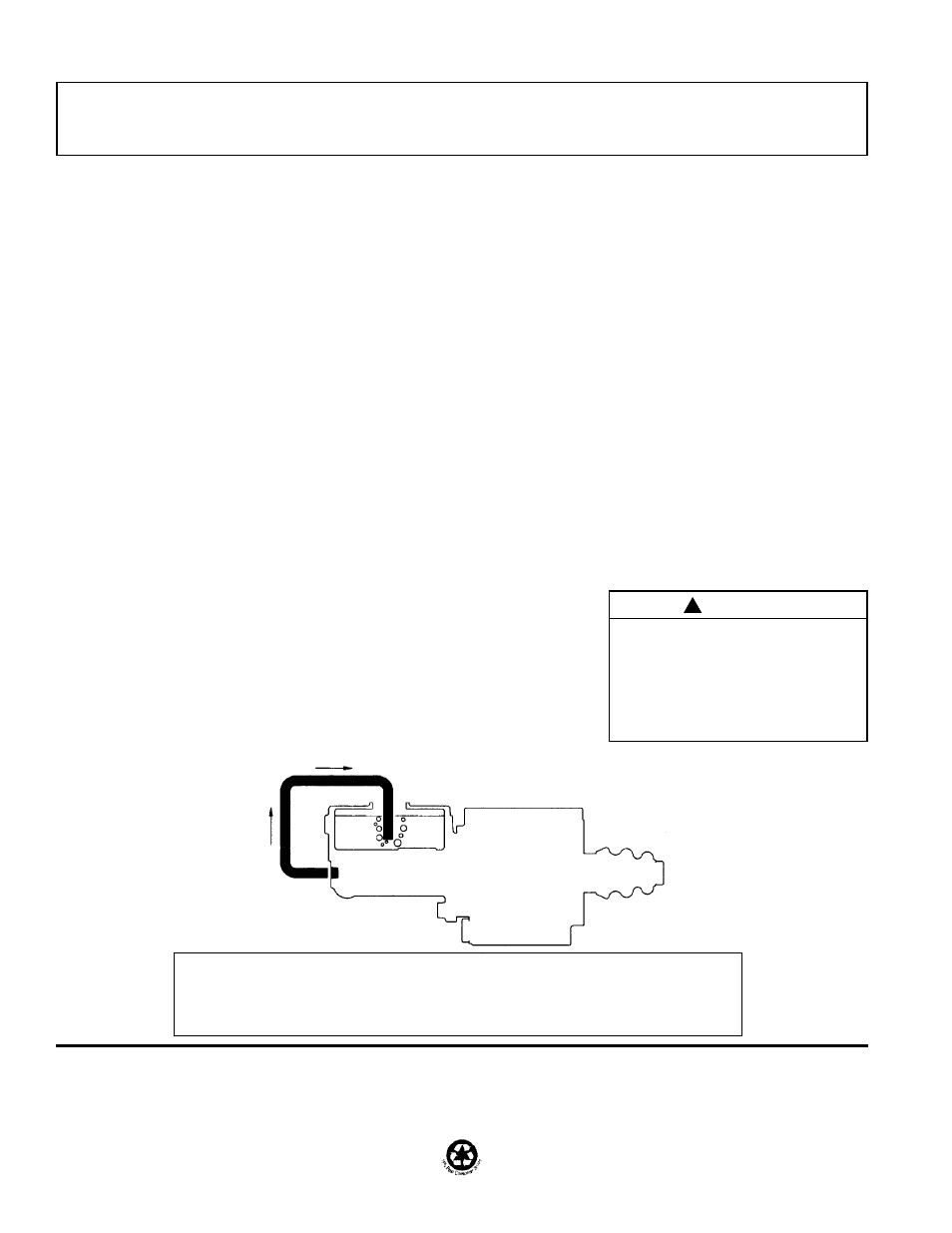

BENCH BLEEDING

INSTRUCTIONS

(Refer to Figure 5)

This process can be done in a

bench vise or on the vehicle with

master cylinder mounted to power

assist section.

Remove master cylinder filler cap

assembly.

Connect a length of tubing to an

outlet port and immerse the other

end below the fluid level in the

master cylinder reservoir. Keep

reservoir fluid within 12.7 mm

(.50") of inside reservoir top.

Actuate master cylinder piston

with a smooth object large enough

to hold the small internal piston

from coming out. Slowly stroke

and release master cylinder

piston. SEE CAUTION BELOW.

Repeat until air bubbles in reservoir

have ceased.

Remove tubing. This should be

done quickly so the loss of fluid

will be minimized.

If cylinder was bench bled in a

vise, it must now be attached

securely to the power assist

section and mounted on vehicle.

Finish all plumbing connections

before continuing to step 7.

1.

2.

3.

4.

5.

6.

Bleed remaining air from system

by depressing brake pedal and

opening bleeder fitting closest to

master cylinder. Close bleeder

fitting before brake pedal is re-

leased. Continue to next bleeder

port. In all cases the bleeder fit-

tings must be closed before the

brake pedal is released or air will

be pulled in through the bleeder

and ingest unwanted air in the

system.

Fill reservoir to within 12.7 mm

(.50") of top. Install filler plug and

torque 33.9-40.7 Nm (25-30 (lbs-ft).

Be certain all fittings are tight to

avoid any leaking.

Actuate pedal several times. If

brake pedal feels spongy, check

for system leaks and repeat

bleeding process.

CAUTION

Care must be taken so as not to over

stroke this cylinder. The cylinder does

not incorporate a piston stop. Over

stroking this cylinder may cause it to

leak from push rod end of cylinder.

Maximum recommended stroke for

this cylinder is 31.8 mm (1.25").

7.

8.

9.

10.

!!!!!

Output

Reservoir

FIGURE 5

MICO has made every attempt to present accurate information in catalogs, brochures and other

printed material. MICO can accept no responsibility for errors from unintentional oversights that

may exist. Due to a continuous program of product improvement, both materials and specifications

are subject to change without notice or obligation.

MICO is a registered trademark of MICO, Incorporated. MICO is registered in the U.S. Patent and Trademark office as well as in Canada, Great Britain, South Korea and Australia.

MICO, Incorporated

1911 Lee Boulevard (Zip Code 56003-2507)

P.O. Box 8118 / North Mankato, MN U.S.A. 56002-8118

(

(507) 625-6426 Facsimile (507) 625-3212

MICO West Division

701 East Francis Street (Zip Code 91761-5514)

P.O. Box 9058 / Ontario, CA U.S.A. 91762-9058

(

(909) 947-4077 Facsimile (909) 947-6054

Revised 3/98

Printed in U.S.A