Metric con ver sion char t – Top Flite TOPA0300 User Manual

Page 6

❏

Nylon Str

apping T

ape

(required f

or bending sheeting)

❏

Masking T

ape (required f

or constr

uction)

❏

Sandpaper (coarse

, medium, fine g

rit)*

❏

T

-Bar Sanding Bloc

k (or similar)

❏

Chalk Stic

k (local dr

ug store)

❏

W

a

x

ed P

aper

❏

Thin Cardstoc

k or a File F

older

❏

Lightw

eight Balsa Filler

, such as Hob

bico

Hob

b

yLite

™

❏

1/4-20 and 8-32 T

aps and T

ap Wrench

❏

Isoprop

yl Rub

bing Alcohol (70%)

❏

A

uto Body Filler (Bondo

®

or similar)

❏

Dremel

®

Moto-T

ool

®

or similar (optional)

*NO

TE:

On our w

o

rkbench, w

e

ha

v

e

f

o

ur 11”

T

-Bar sanders

, equipped with #50, #80, #150

and #220-g

rit sandpaper

. This setup is all that is

required f

or almost an

y sanding task. Custom

sanding b

loc

ks can be made from balsa f

o

r

sanding hard to reach spots

. W

e

also k

eep

some #320-g

rit w

et-or-dr

y sandpaper handy f

o

r

finish sanding bef

ore co

v

e

ring.

COMMON ABBREVIA

TIONS USED IN THIS

BOOK AND ON THE PLANS:

Deg = Deg

rees

Ele

v

= Ele

v

ator

Fuse = Fuselage

LE = Leading Edge (front)

LG = Landing Gear

Lt = Left

Ply = Plyw

ood

Rt = Right

Stab = Stabiliz

er

TE = T

railing Edge (rear)

”

= Inches

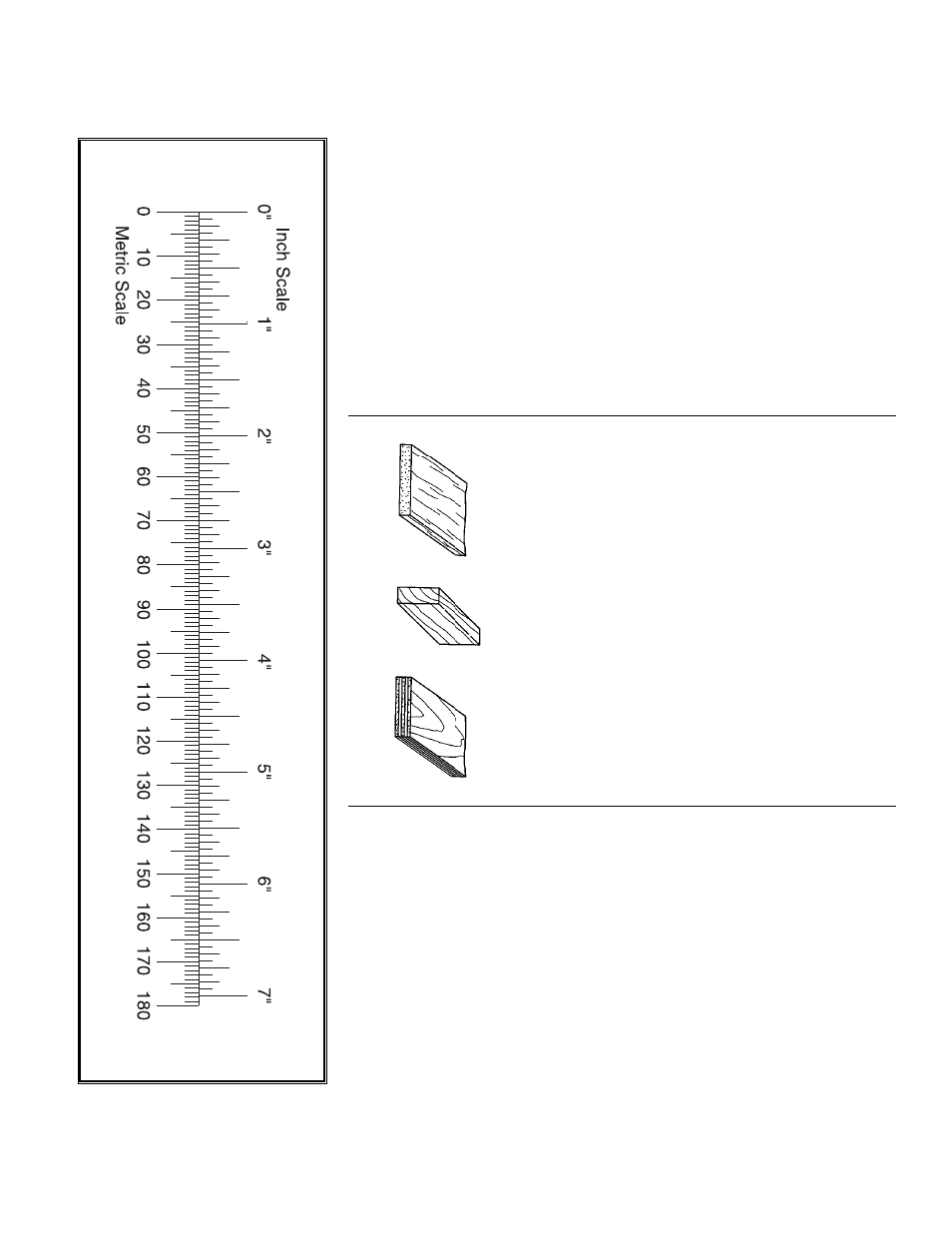

TYPES OF W

OOD

B

ALSA B

ASSW

OOD PL

YW

OOD

Metric Con

ver

sion Char

t

Inches x 25.4 = mm (conversion factor)

1/64” =

.4

mm

1/32” =

.8

mm

1/16” =

1.6

mm

3/32”

=

2.4 mm

1/8”

=

3.2 mm

5/32”

=

4.0 mm

3/16”

=

4.8 mm

1/4”

=

6.4 mm

3/8”

=

9.5 mm

1/2”

=

12.7 mm

5/8”

=

15.9 mm

3/4”

=

19.0 mm

1”

=

25.4 mm

2”

=

50.8 mm

3”

=

76.2 mm

6”

=

152.4 mm

12”

=

304.8 mm

18”

=

457.2 mm

21”

=

533.4 mm

24”

=

609.6 mm

30”

=

762.0 mm

36”

=

914.4 mm

6