A=a a a, Attac h the stab and fin – Top Flite TOPA0300 User Manual

Page 37

NO

TE: Due to the v

ariety of hook-up methods

pref

erred b

y

diff

erent modeler

s, we do not

pr

o

vide an

y thr

ottle linka

g

e

har

d

ware in most

of our kits. Ho

we

ver

, we do off

er the f

ollo

wing

method as one that w

orks well. Y

ou pr

obab

ly

ha

ve the materials b

uried some

where under

y

our w

o

rkbenc

h.

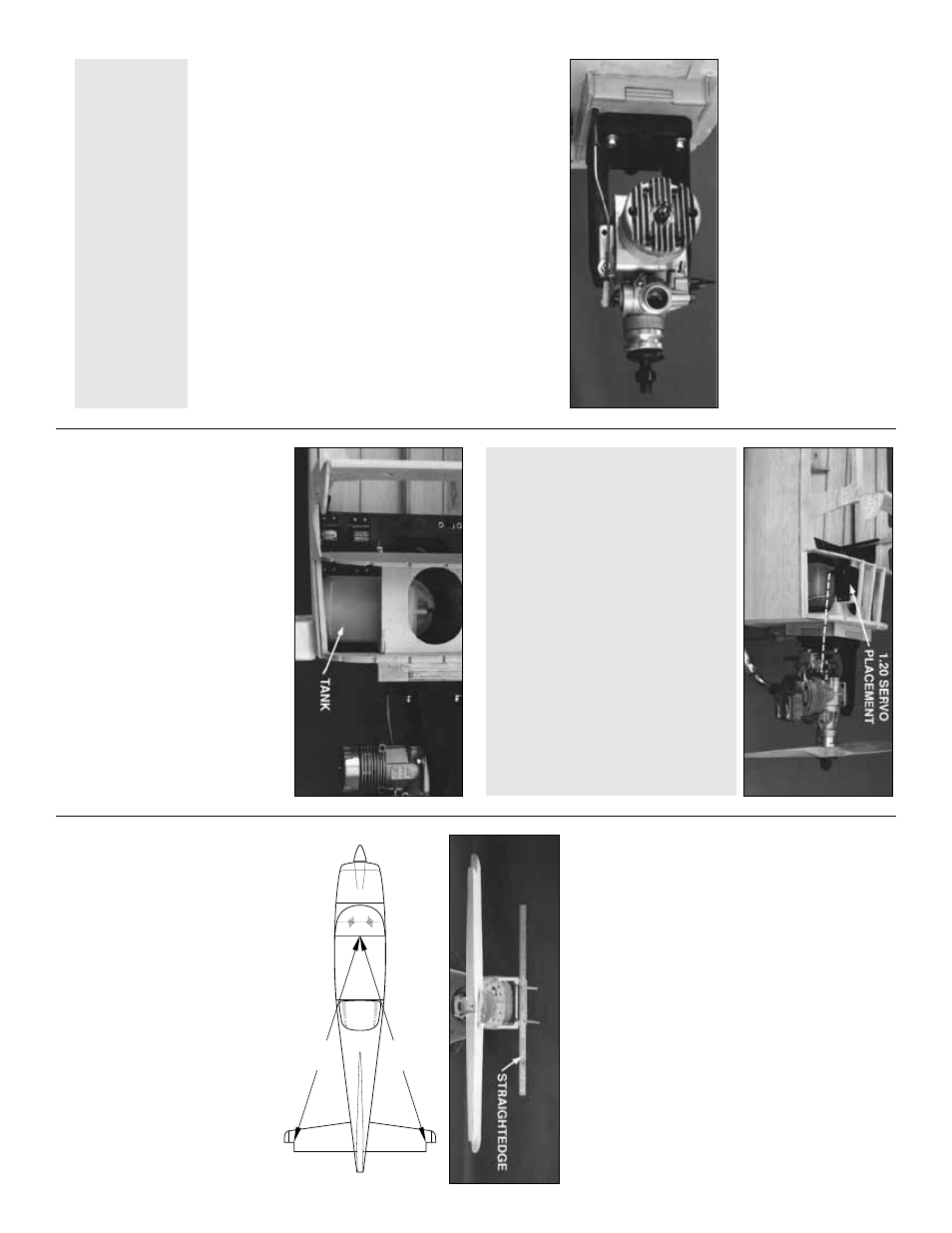

❏

7. Inser

t a shor

t length of outer pushrod tube

through the throttle hole in the Fire

w

all. Attach a

Ball Link to the throttle ar

m on the engine

. Scre

w

a Ball Link Soc

k

et onto a 2-56 x 12” threaded

wire pushrod. Inser

t the pushrod through the

outer pushrod tube

, then attach the Ball Link and

Soc

k

et. Bend a “dog leg” in the pushrod near the

ser

v

o so that the wire will be just abo

v

e

the

ser

v

o

hor

n. Attach the pushrod wire to the ser

v

o

with a small pushrod Connector

. Connect the

ser

v

o

to y

our r

adio and adjust the pushrod

length and position on the ser

v

o

hor

n to obtain

full throttle mo

v

ement.

❏

8. Assemb

le a

12 oz. Great Planes Fuel

T

ank

(GPMQ4105) with the

right angled

fuel

pic

kup tube

. The T

ank is installed “

side

w

a

ys

”

under the Instr

ument P

anel with the bac

k end

pointing to

w

ard the r

ight side of the fuse

. W

o

rk

a

small piece of 1/4” f

oam r

u

b

ber abo

v

e

and belo

w

the T

ank, then slide a couple of scr

ap balsa

stic

ks under the tank to secure it in position and

pro

vide throttle pushrod clear

ance

. W

e

fle

w all of

our test flights with the tank mounted in this

position and e

xper

ienced no prob

lems

.

❏

9

.

Mar

k and dr

ill 1/4” fuel tube holes through

the fire

w

all, being careful not to damage the tank.

Install both the fuel supply and pressure tubes

.

F

or ease of fueling w

e

suggest a

Great Planes

Fuel Filler V

alve

(GPMQ4160) that can be

mounted on the co

wling dur

ing final assemb

ly

.

❏

1. Chec

k the fit of the Stab with the Stab

Saddle

. Mak

e an

y adjustments to the Stab

Saddle v

e

ry

carefully

, so that y

ou

don’t c

hang

e

the b

u

ilt-in incidence angle

.

❏

2. Put the stab on the saddle and add a small

w

eight to hold it in place

. Place a 36”

str

aightedge across the Wing Saddle and clip it

to F-2B

. Sight across the top of the Stab to the

str

aightedge from six to ten f

eet behind the

model. If both Stab tips are not equidistant

belo

w the str

aightedge

, mak

e

small

adjustments

to the Stab Saddle to correct the prob

lem. Use a

str

ing, pinned to the top center of F-2, to

equaliz

e the distance of the Stab tips

.

A=A

A

A

Attac

h the stab and fin

Use scr

ap 3/16” or 1/4” plyw

ood to mak

e

tw

o

ser

v

o

mounting b

loc

ks appro

ximately 3/4”

square

. Use epo

xy to glue these b

loc

ks as

sho

wn abo

v

e

the Fuel T

ank Roof so that the

ser

v

o

hor

n aligns with the throttle ar

m on the

engine

. Use the same pushrod technique as

descr

ibed in Step 8 f

or a direct hookup

. The

do

wn-side to this method is that the ser

v

o

will

not be accessib

le after sheeting without cutting

into the top of the fuse

...b

ut, because ser

v

o

s

are gener

ally quite reliab

le

, this ma

y ne

v

er

be necessar

y.

SER

V

O

OPTION FOR 1.20 ENGINE

T

o

simplify the throttle hookup f

or a 1.20 4-

strok

e

engine y

ou ma

y w

ant to consider the

follo

wing suggestion.

37