Sheet the bottom of the wing – Top Flite TOPA0300 User Manual

Page 22

❏❏

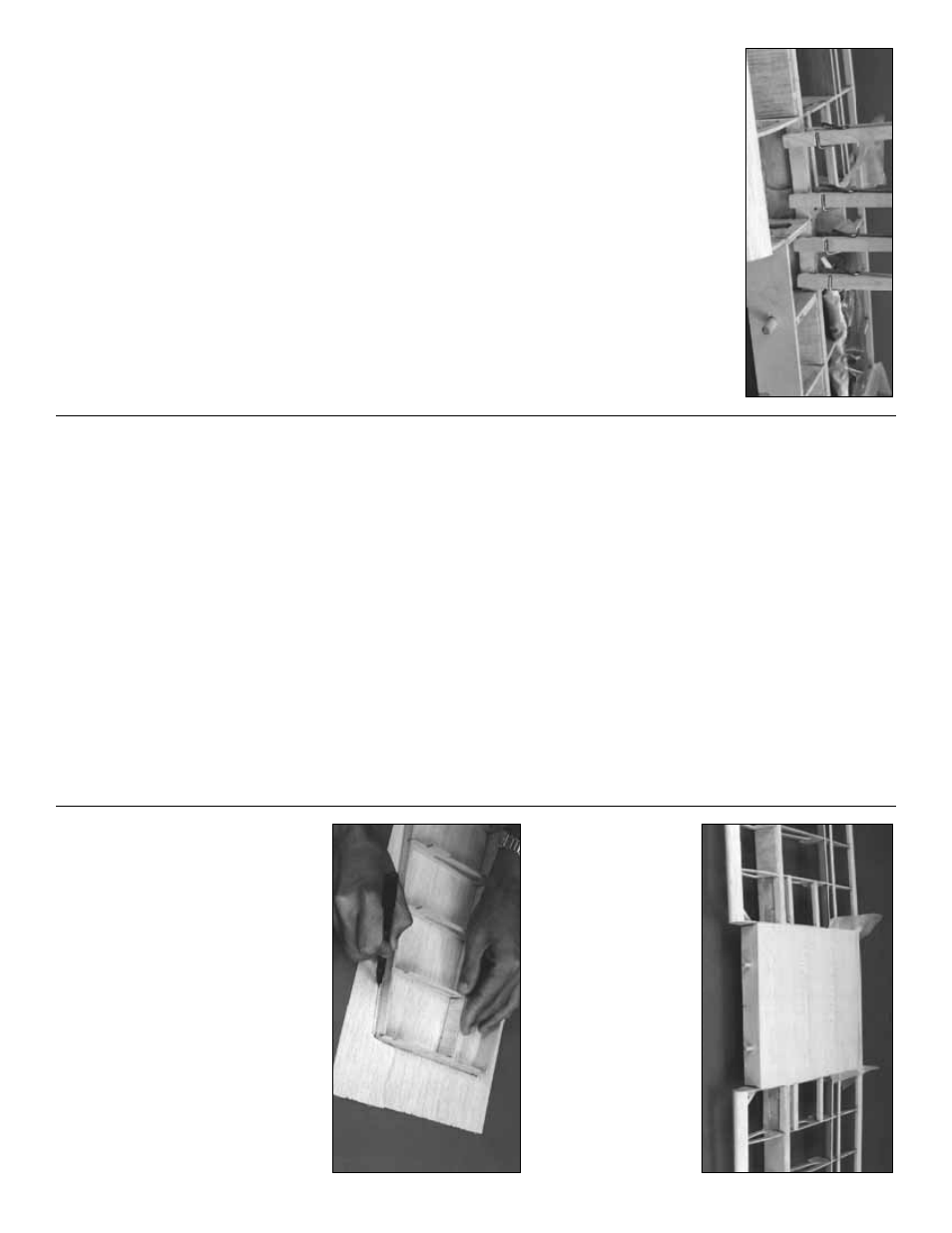

6. T

est fit the 1/16” die-cut ply bottom

Spar

Joiner

in the slots

. J

ust lik

e the P

olyhedr

al

Br

aces

, the Spar Joiners ha

v

e

one end that is

longer than the other

. The longer end points

to

w

ards the wing tip

. Equally sand the ends if

needed f

or a good fit betw

een the r

ibs

. Use 6-

min

ute or 30-Min

ute Epo

xy to glue the Spar

Joiners in position.

Clothes pins mak

e

handy

clamps while the epo

xy cures

.

❏❏

7. T

u

rn

the wing o

v

er and repeat the

process of installing the Spar Joiners on the top

wing spars

.

Our suggested wing sheeting process allo

ws

y

ou to sheet each of the wing panels with one

skin per side — plus a little e

xtr

a f

or the flaps

.

This technique is better than sheeting the wing

with individual sheets

, and allo

ws y

ou to

pre-

sand

all of the seams that will be o

v

er open

str

ucture

.

All balsa sheeting will usually bend when it’

s cut

from the log since inter

nal stresses are relie

v

ed.

F

or the best results

, tr

im the edges of the wing

sheeting with a long metal str

aightedge and a

sharp

knif

e bef

ore joining them. Y

ou ma

y also

tr

y tur

ning the sheets diff

erent w

a

ys to see if the

edges will line up e

v

enly

. If the bend is only

slight, use 150-g

rit sandpaper on a long sanding

b

loc

k to smooth out the cur

v

ature

.

For more

inf

ormation on making wing skins ref

er bac

k

to pa

g

e

10 f

or the

Hot Tip.

NO

TE: Do the f

ollo

wing steps f

or both the

right and left wing panels.

❏

1. Sor

t through the remaining 1/16” x 3” x 36”

balsa sheets and pic

k out the 6 best sheets to

be used f

or the top surf

aces of the outboard

wing panels

. Pic

k the best three sheets from the

1/16” x 3” x 21” sheeting to use f

or the top

Center Section skin

❏

2. La

y w

a

x

e

d paper o

v

er a flat,

smooth

w

o

rk

surf

ace

.

❏

3. Mak

e

f

our outboar

d wing skins

b

y

edge

gluing

three

1/16” x 3” x 36” balsa wing sheets

together to mak

e

(f

our) 9” x 36” skins

. Mak

e

one

center section

skin using

four

sheets of 1/16” x

3” x 21” balsa. This skin will be cut in half

after

sanding

to mak

e

tw

o 12” x 10-1/2”

skins

. Ref

er

to page 10 f

or tips on making skins

.

NO

TE: When sheeting, be sure that the

wing is resting squarel

y on the center

section Jig Bloc

ks, weighted do

wn on a flat

surface

, and that the W

-14 jig tabs are in

solid contact with the b

u

ilding surface

.

❏

4. Hold a 1/16” x 12” x 10-1/2” center section

skin on the bottom surf

ace of the wing with one

edge b

utted up to the LE. Mar

k

the per

imeter of

the skin. The

side edg

es of the skin

should be

centered on the joint

betw

een r

ibs W

-3 and W

-

4. Cut the skin close to the correct siz

e then

sand

it f

o

r an e

xact fit.

❏

5. Glue the center skin in position using

medium or thic

k CA. Hold the skin in contact

with the fr

ame until the glue has cured.

❏❏

6. Fit one of the 9” x 36” skins in place on

an outboard wing panel, with one long edge

b

utted tightly against the inner LE. The inboard

edge should o

v

er

lap the center section. T

ape the

skin in place

. With a fle

xib

le r

u

ler

, mar

k the edge

that mates with the center panel. Flip the wing

o

v

er and mar

k the tip and TE from the bac

k side

.

Allo

w an e

xtr

a 1/4” around these tw

o edges

.

Remo

v

e

the skin and cut it to the mar

k

ed siz

e

. If

necessar

y,

use 220 g

rit sandpaper to

fine tune

the inboard edge f

or an

e

xact

fit.

The photo at

step #9 sho

ws appro

ximately what y

our sheet

should look lik

e when it’

s tr

immed.

Sheet the bottom of the wing

22