Complete the fusela g e top – Top Flite TOPA0300 User Manual

Page 39

❏

12. Scre

w a n

y

lon

Cle

vis

onto a

2-56 x 4”

threaded Pushr

od

at least 14 re

v

olutions

. Slide

a Silicone Retainer o

v

er the Pushrod, onto the

aft end of the Cle

vis

. Clip the Cle

vis onto the

Rudder T

orque Rod Hor

n and center the T

orque

Rod (i.e

., neutr

al r

udder). With the ser

v

o

centered, position the 4” pushrod o

v

er the Split

Coupling Slee

v

e

, then mar

k it where it will just

miss touching the other pushrod already in the

Slee

v

e

. Repeat this procedure f

or the Ele

v

ator

.

❏

13. T

rim and

c

lean

(as y

ou did dur

ing Step 11)

the shor

t Pushrods

, then push them into the aft

end of the Coupling Slee

ve

s

. Use

liquid Flux and

Silver Solder

to solder the Pushrods into the

Coupling Slee

v

e

s

. If y

ou ha

v

en’t done this

oper

ation bef

ore

, read

Hot Tip f

o

r Silv

er Solder

ing.

No

w that most of the fiddly w

o

rk

is finished,

clean up y

our bench and let’

s get bac

k to what

man

y people consider “the fun stuff

”–finishing

the airfr

ame

.

❏

14. If y

ou are installing a beacon light on the

Fin, dr

ill a hole through the Stab that matches

the location of the conduit y

ou installed ear

lier

.

❏

15. Mix up some 30-Min

ute Epo

xy and add a

dash of microballoons to “thic

k

en it up” and

create a fillet. Apply the epo

xy mixture to the LE,

TE and bottom of the Fin. Align the Fin, and

press it into position. Use masking tape to hold it

in position while the epo

xy cures

. Once the tape

is in place

, chec

k the Fin to mak

e

sure that it’

s

on the fuse center

line

and

per

pendicular to the

Stab

. Use an

y lefto

v

e

r epo

xy to f

o

rm

a small fillet

around the base of the Fin.

❏

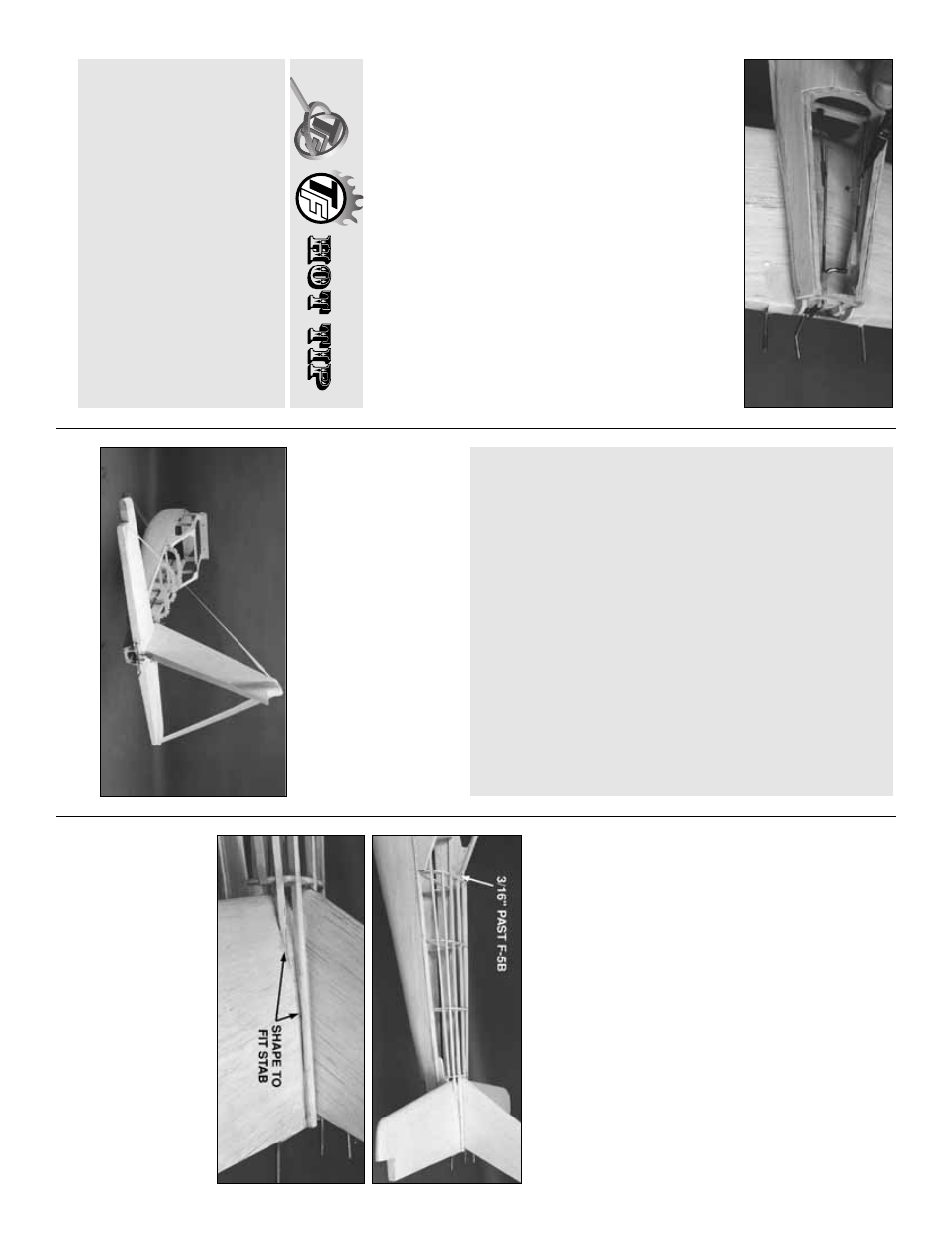

1. Cut 3/16” x 3/16” x 24” balsa Str

ingers to fit

the top aft f

o

rmers from F-5B to the top of the

Stab

. T

aper the Str

ingers to b

lend with the

surf

ace of the Stab

. Lea

v

e

about 3/16” of

eac

h

Str

inger protr

uding

forwar

d

of F-5B to pro

vide a

“ledge” f

or the rear windo

w

. Use thin CA to glue

them in place

.

Complete the fusela

g

e

top

B

. Roughen the area to be soldered with fine

sandpaper

, then clean again.

C

. Assemb

le the items to be soldered.

D

. Apply a small amount of solder

ing flux. Acid

based liquid flux w

o

rks best when one or more

of the items is steel.

E. Heat the metal with a solder

ing gun or iron,

and apply solder to the metal. The metal m

ust

get hot enough to melt the solder and the

solder m

ust flo

w freely into the joint.

F.

Do not mo

v

e

the par

ts until the solder has

cooled.

G. T

est the joint b

y

pulling hard.

H. Clean off the e

xcess flux with alcohol or

solv

ent. Coat the par

ts with a v

e

ry

fine film of oil.

HO

T TIP FOR SIL

VER SOLDERING

Use this process when solder

ing metal to

metal, such as br

ass tube to wire

, or pushrod

ends to wire

.

A. Thoroughly clean the items to be soldered

with alcohol or deg

reasing solv

ent. P

a

y special

attention to the

inside

of the Threaded

Br

ass Couplers

.

39