Top Flite TOPA0300 User Manual

Page 44

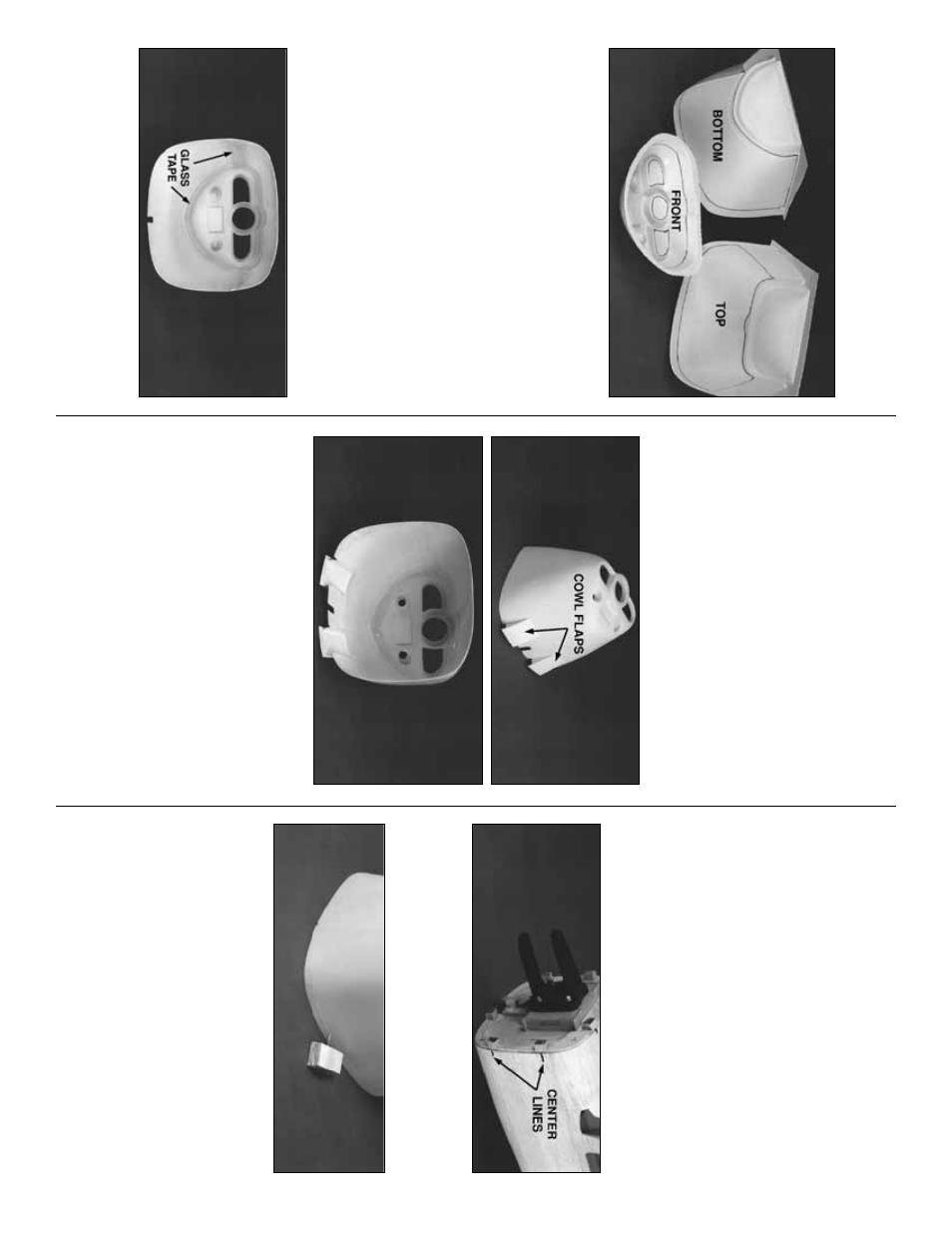

❏

1. Use a

ne

w # 11 b

lade

in a hob

b

y

knif

e to

score

around the

cutlines

inside all three par

ts

of the ABS co

wl as sho

wn in the photo

. Fle

x

the

ABS along the scores until the e

xcess mater

ial

breaks free

. Use a Moto-T

ool and cutting b

urr to

cut the air intak

es and propshaft opening.

❏

2. Use a sanding b

loc

k to clean up the edges

and to mak

e an

y adjustments that ma

y be needed

for a nice flush fit. Roughen the inside edges of the

joints with coarse sandpaper

, then fit the three

par

ts together and secure them with tape

. Carefully

wic

k thin CA around the joints and allo

w the par

ts

to cure

. Do

not

use CA acceler

ator

.

❏

3. F

or added strength, epo

xy 1”-wide

fiberglass cloth tape across all of the seams on

the inside of the co

wl.

IMPOR

T

ANT

: Hot air g

enerated b

y

the

engine MUST be vented fr

om the co

wl

or

y

our engine will o

verheat and quit!

While

w

e

e

xper

ienced no o

v

erheating prob

lems with

our

engine running slightl

y

ric

h

and both air

inlets open, y

ou ma

y pref

er

not

to open

both

air inlets

. By lea

ving only the inlet in front of

the cylinder open,more air is f

orced directly

o

v

er the cylinder and out through the co

wl

flaps

. If y

ou choose to open the second inlet, a

dumm

y cylinder head or baffle could be

installed behind the opening to restr

ict the

air-flo

w

into the co

wl.

❏

4

.

Use a hob

b

y

knif

e to cut along the

embossed lines on the inside of the co

wl f

or the

co

wl flap openings

. Use the patter

ns on the plans

to cut the co

wl flap sides from e

xcess 1/16” ply

lefto

v

er from the ser

v

o

hatch die-cut sheet. Cut

out the

co

wl flaps

from the ABS sheet, using the

cut lines f

o

r ref

erence

. Glue the co

wl flap sides to

the inside edges of the co

wl, then center the flap

across the sides and glue it in place

.

❏

5. Fill the seams on the outside of the co

wl

with

Bondo

®

type automotiv

e body filler

.

❏

1. Mount the engine

. Slide the Co

wl into

position as f

ar as it will fit. Cut a slot in the Co

wl

for the Nose Gear

. Sand the hardw

ood Co

wl

Mounting Bloc

ks and balsa Co

wl Ring until the

Co

wl fits flush with the fuse

. With the co

wl in

position, install a spinner on the prop shaft and

chec

k the clear

ance around the front of the

Co

wl. Sand the aft edge of the Co

wl until the

spinner is centered and is 1/16” a

w

a

y

from the

front of the Co

wl.

❏

2. Dr

a

w

a shor

t line to e

xtend the center

line of

each Co

wl Mounting Bloc

k onto the f

o

rw

ard

edge of the balsa sheeting.

❏

3. Sandwich a T

-pin betw

een tw

o scr

aps of

1/4” balsa to mak

e

a quic

kie height gauge

. Glue

the top to the bottom piece of balsa with CA.

Hold the height gauge and the Co

wl flat on the

w

o

rk

bench, then rotate the height gauge around

the per

imeter of the co

wl to

lightl

y

scr

ibe a line

.

NO

TE: A pen or pencil ma

y be substituted

fo

r the “Pin” so long as the point is 1/4”

abo

ve the w

ork surface

.

Fit the co

wl to the fusela

g

e

and engine

Assemb

le the co

wl

44