3 high gas pressure fault test – AERCO BMK 6000 Dual Fuel User Manual

Page 83

Benchmark 6000 DF Installation, Operation & Maintenance Manual

CHAPTER 6 – SAFETY DEVICE TESTING

OMM-0096_0B

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 83 of 219

GF-141

Ph.: 800-526-0288

03/21/2014

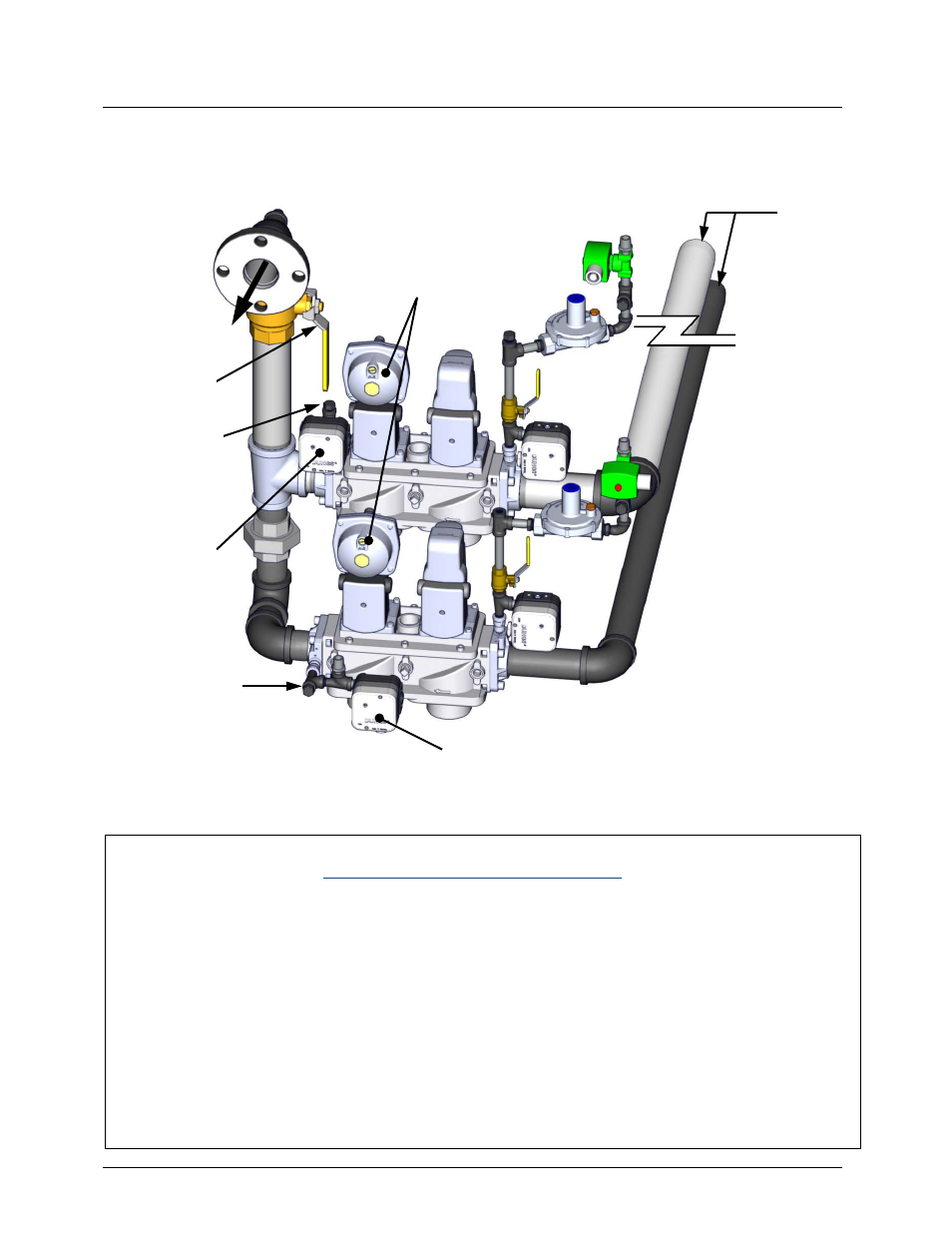

6.3 HIGH GAS PRESSURE FAULT TEST

To simulate a high gas pressure fault, refer to Figure 6-1B and perform the following steps. The

instructions below apply to both the Natural Gas and Propane gas trains.

Figure 6-1B. High Gas Pressure Test

High Gas Pressure Fault Test

1.

Remove the 1/4“ plug from the Tee next to the NATURAL GAS High Gas Pressure Switch,

shown in the upper half of Figure 6-1B.

2.

Install a NPT-to-barbed fitting and a 0 – 16” W.C. manometer where the 1/4” plug was

removed. Open the ball valve at the High Gas Pressure switch.

3.

Apply the readings of the manifold pressure taken in Step 11 of section 4.4 (for Natural

Gas) and Step 10 of section 4.5 (for Propane), and plug them into the following formulas,

which calculate the maximum allowable gas pressure:

•

Natural Gas Pressure

______ x 1.5 = ______ max gas pressure

•

Propane Gas Pressure

______ x 1.5 = ______ max gas pressure

4.

Remove the cover from the High Gas Pressure switch and set the dial indicator to 20 (the

maximum).

NATURAL GAS

HIGH GAS PRESSURE

SWITCH

(10.5” W.C.)

PROPANE HIGH GAS PRESSURE SWITCH

(6.3” W.C.)

GAS

INLET

TO AIR/FUEL

VALVE

NATURAL GAS

TEE with 1/4" PLUG

(Install manometer

here for HIGH GAS

PRESSURE test)

MANUAL SHUT-

OFF VALVE

PROPANE

TEE with 1/4" PLUG

(Install manometer

here for HIGH GAS

PRESSURE test)

DOWNSTREAM

SSOV with POC

SWITCH