8 gas supply piping – AERCO BMK 6000 Dual Fuel User Manual

Page 23

Benchmark 6000 DF Installation, Operation & Maintenance Manual

CHAPTER 2 – INSTALLATION

OMM-0096_0B

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 23 of 219

GF-141

Ph.: 800-526-0288

03/21/2014

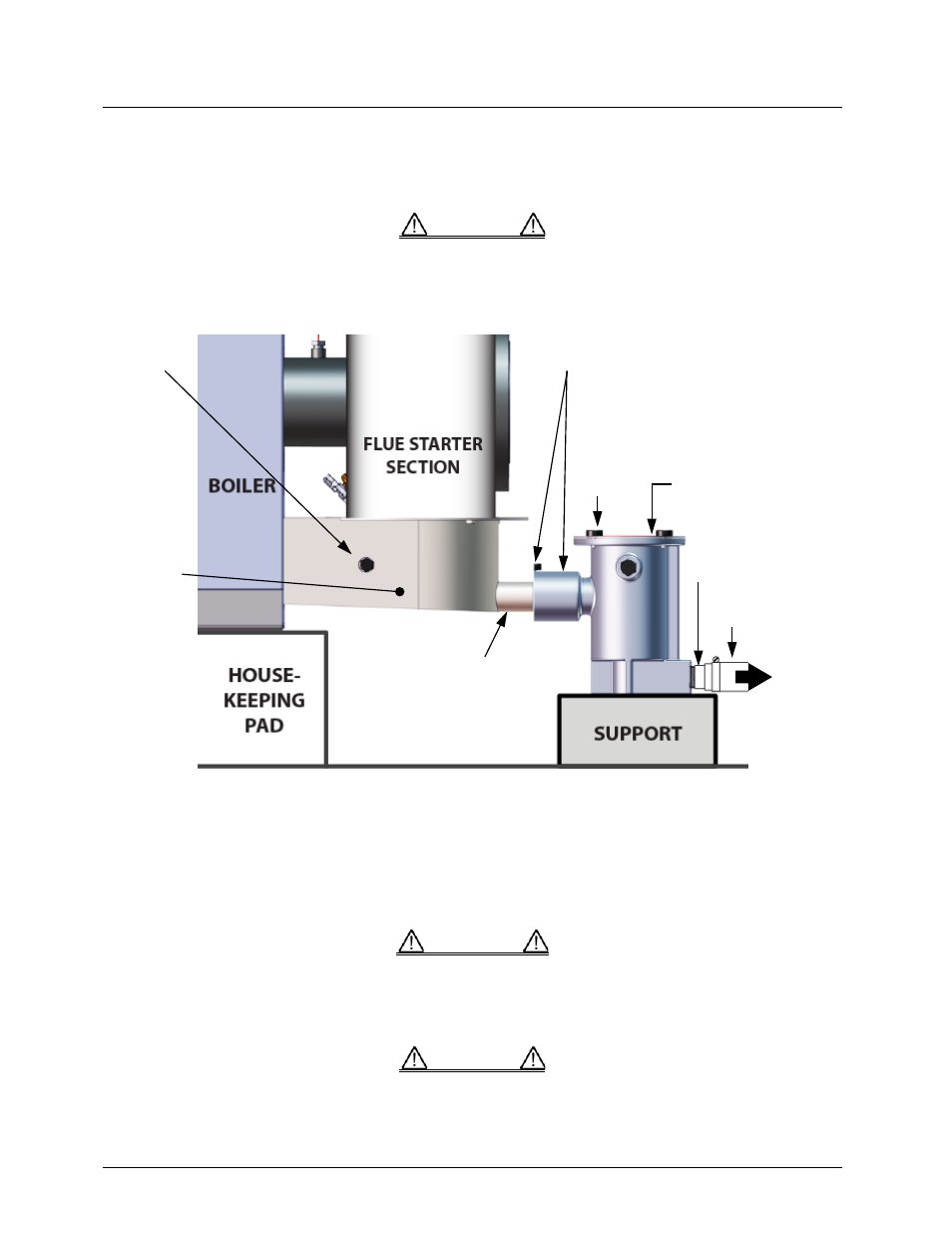

If a floor drain is not available, a condensate pump can be used to remove the condensate to

drain. The maximum condensate flow rate is 40 GPH. The condensate drain trap, associated

fittings and drain line must be removable for routine maintenance.

Use PVC, stainless steel, aluminum or polypropylene for condensate drain

piping (Figure 2-6). DO NOT use carbon or copper components.

Figure 2-7. Sample Condensate Trap Installation – Side View

2.8 GAS SUPPLY PIPING

The AERCO Benchmark Gas Supply Design Guide, GF-2030 must be consulted prior to

designing or installing any gas supply piping.

NEVER USE MATCHES, CANDLES, FLAMES OR OTHER

SOURCES OF IGNITION TO CHECK FOR GAS LEAKS

.

Many soaps used for gas pipe leak testing are corrosive to metals.

Therefore, piping must be rinsed thoroughly with clean water after leak

checks have been completed.

CAUTION

WARNING

CAUTION

COMBUTION

ANALYZER

PROBE PORT

EXHAUST

MANIFOLD

3/4” NPT

NIPPLES

T O

FLOOR

DRAIN

CONDENSATE

TRAP (P/N 24060)

TOP

COVER

THUMB

SREWS

(4 each)

1” DIAM.

HOSE

NOTE

HOUSKEEPING

PAD MUST NOT

EXTEND

UNDER THE

CONDENSATE

ASSEMBLY.

TRAP INLET

INTEGRAL ADAPTOR

AND THUMBSCREW

EXHAUST

MANIFOLD

DRAIN PORT

Tilt down 2° for

gravity flow