AERCO BMK 6000 Dual Fuel User Manual

Page 216

Benchmark 6000 DF Installation, Operation & Maintenance Manual

APPENDIX N – ULTRA-LOW NOX CALIBRATION

Page 216 of 219

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

OMM-0096_0B

03/21/2014

Ph.: 800-526-0288

GF-141

Ultra-Low NOx Natural Gas Combustion Calibration - Continued

NOTE

If NOx readings exceed the target values shown (<9 ppm), increase the O

2

level up to 1% higher than the listed calibration range shown in the table.

Record the increased O

2

value on the Combustion Calibration sheet.

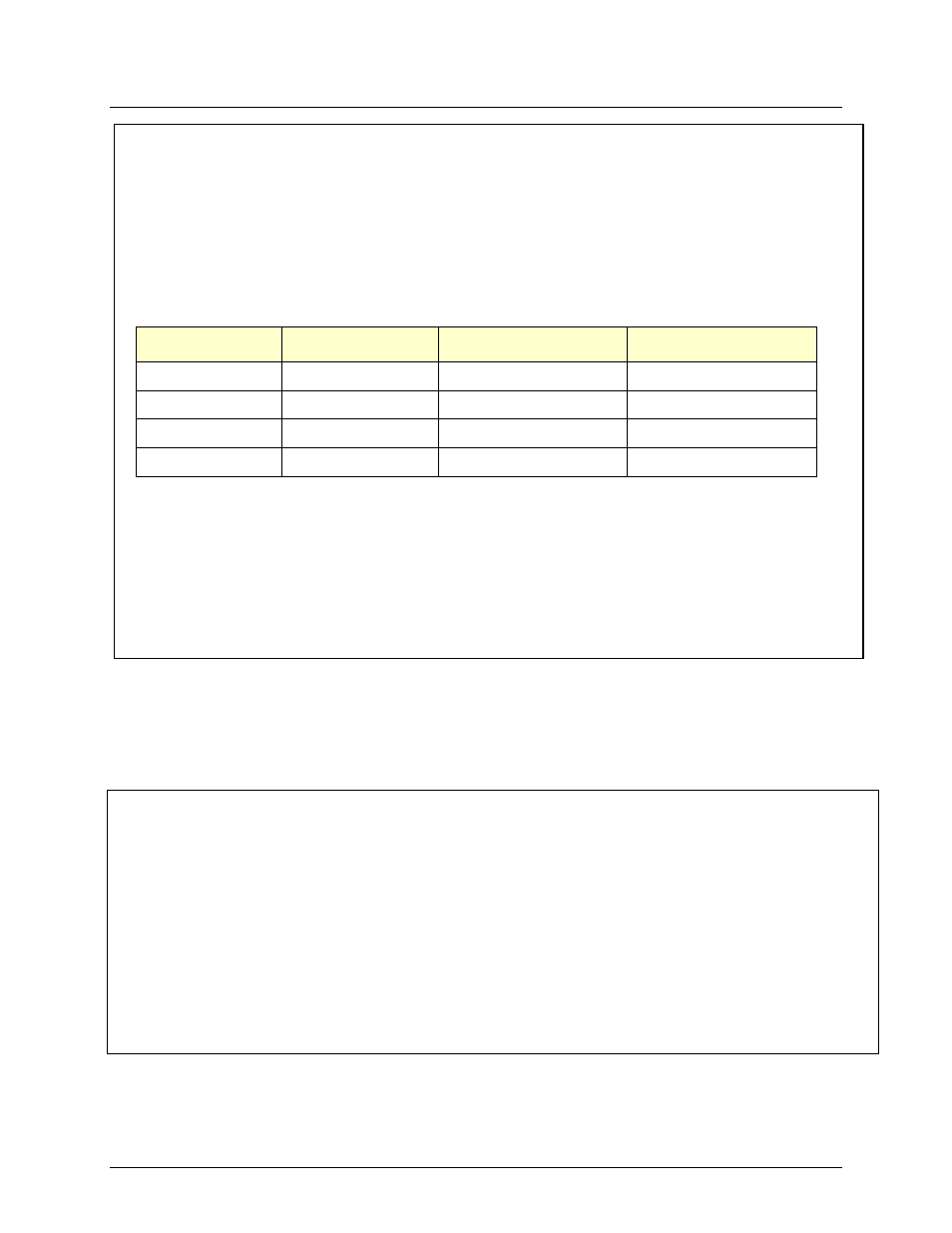

Ultra-Low NOx Combustion Calibration Readings

Valve Position

Oxygen (O

2

) %

Nitrogen Oxide (NOx)

Carbon Monoxide (CO)

60%

5% - 7%

<9 ppm

<100 ppm

45%

5% - 7%

<9 ppm

<100 ppm

30%

5% - 7%

<9 ppm

<100 ppm

18%

5% - 7%

<9 ppm

<100 ppm

29. If the oxygen level at the 18% valve position is too high and the Blower voltage is at the

minimum value, you can adjust the idle screw (TAC valve) which is recessed in the top

of the Air/Fuel Valve (see Figure 4-4). Rotate the screw 1/2 turn clockwise (CW) to add

fuel and reduce the O

2

to the specified level. Recalibration MUST be performed again

from 60% down to 18% after making a change to the idle screw (TAC valve).

30. This completes the ultra-low NOx Natural Gas combustion calibration procedures.

N-2. REASSEMBLY

Once the combustion calibration adjustments are properly set, the unit can be reassembled for

service operation.

Reassembly

1. Set the ON/OFF switch to the OFF position.

2. Disconnect AC power from the unit.

3. Shut off the gas supply to the unit.

4. Remove the manometer and barbed fittings and reinstall the NPT plug using a suitable

pipe thread compound.

5. Remove the combustion analyzer probe from the 1/4” vent hole in the exhaust manifold.

Replace the 1/4” NPT plug in the manifold.

6. Replace all previously removed sheet metal enclosures on the unit.